Integrated block type valve-block hydraulic control system for drilling machine

A hydraulic control system and integrated block technology, which is applied to the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc., can solve the problems of cumbersome connection, troublesome operation, easy heating, etc., and achieve easy maintenance, reduced energy consumption, and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

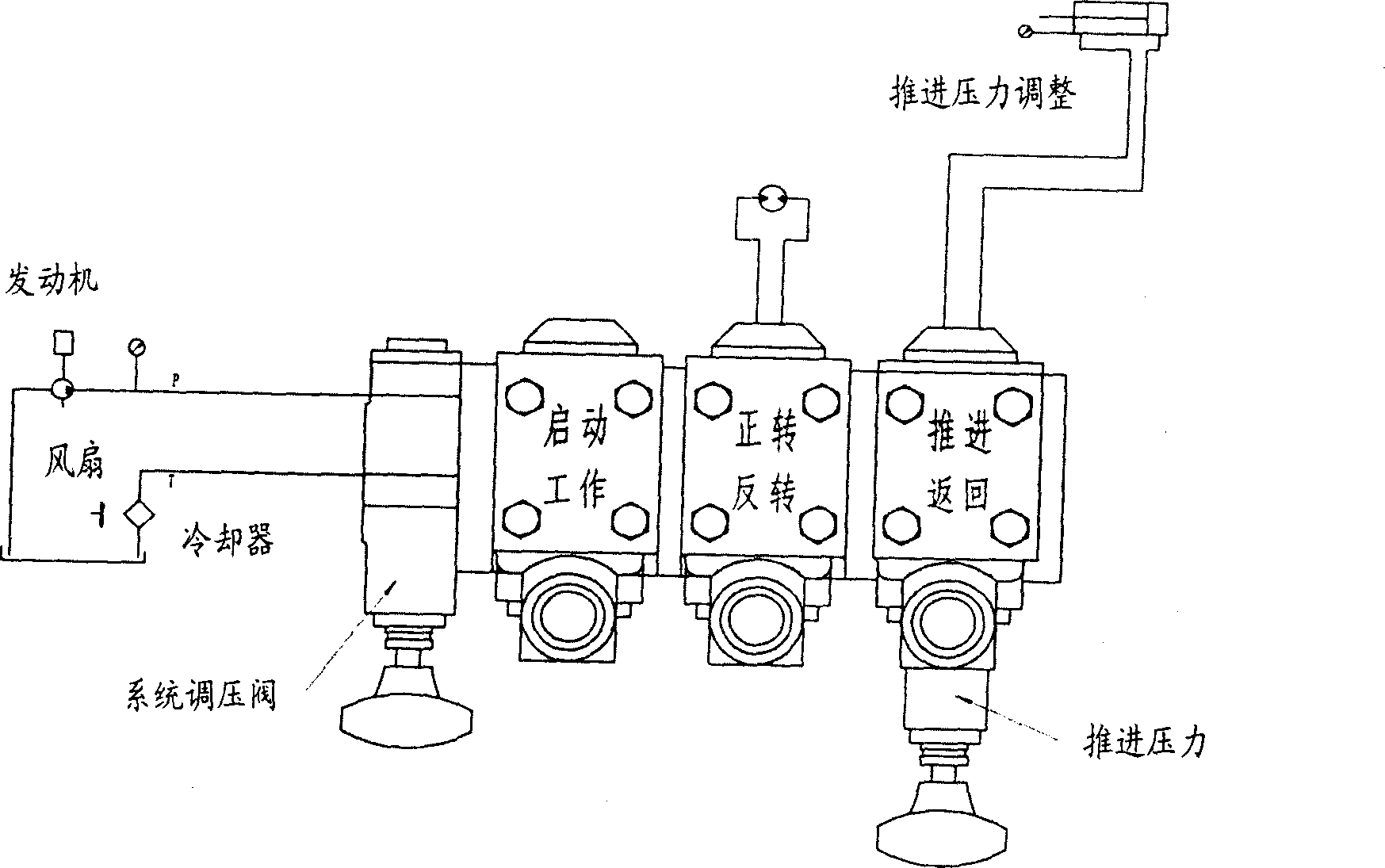

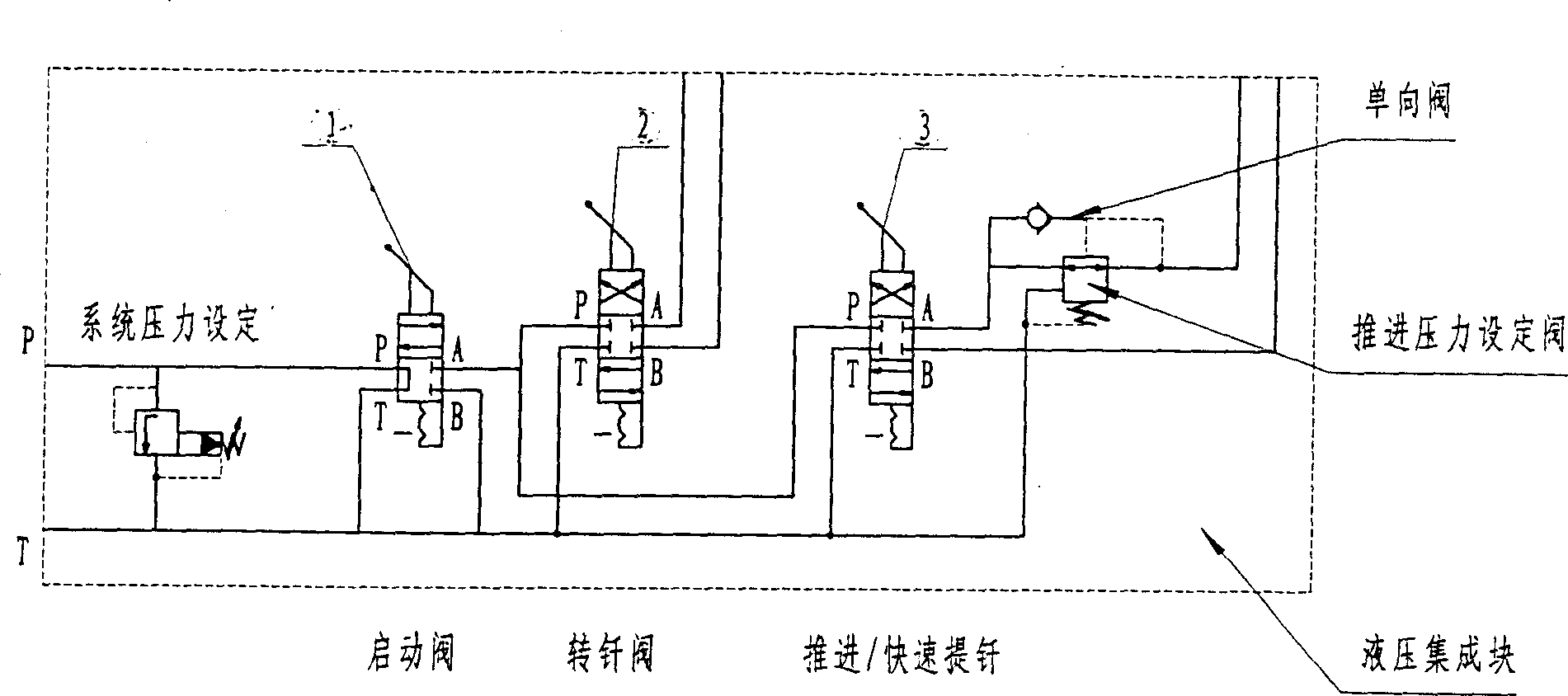

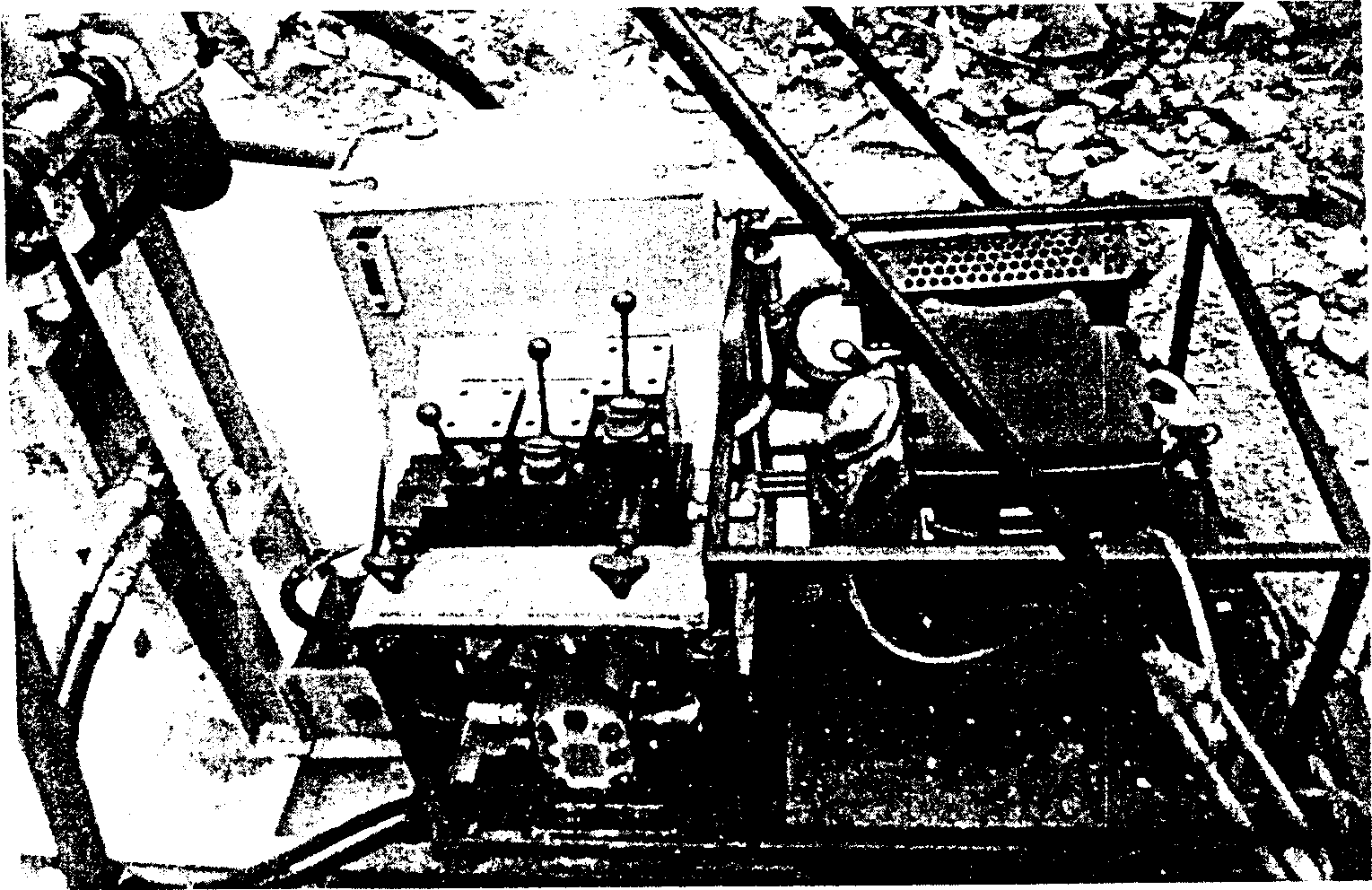

[0010] The structure of the multi-functional full hydraulic mountain drilling rig is mainly composed of two parts: the drill frame and the hydraulic power station. The drill frame part mainly includes the drill frame base, the impactor, and the reducer. The motor, the hydraulic motor, is connected to the hydraulic power unit, the reducer is connected to the thruster through the splint and the slide plate, the impactor is connected to the reducer through the connecting flange, the hydraulic power unit is installed on the drill frame through the pin shaft, and the hydraulic power unit is installed on the drill frame. Lever to control the impactor. Drilling rig control with integrated block hydraulic control system such as figure 1 As shown, the valves that control the action of the drilling machine are assembled on the manifold, and the manifold is directly connected to the actuators of the drilling machine, so that the entire system has only six pipelines, which reduces the num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com