Plate indirect ice-melting and direct ice-melting concurrent ice-storage tank

An ice storage tank and ice melting technology, which is applied in the directions of space heating and ventilation, heating mode, lighting and heating equipment, etc. Heat loss and other problems, to achieve the effect of uniform freezing and melting, reducing scale, and low cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

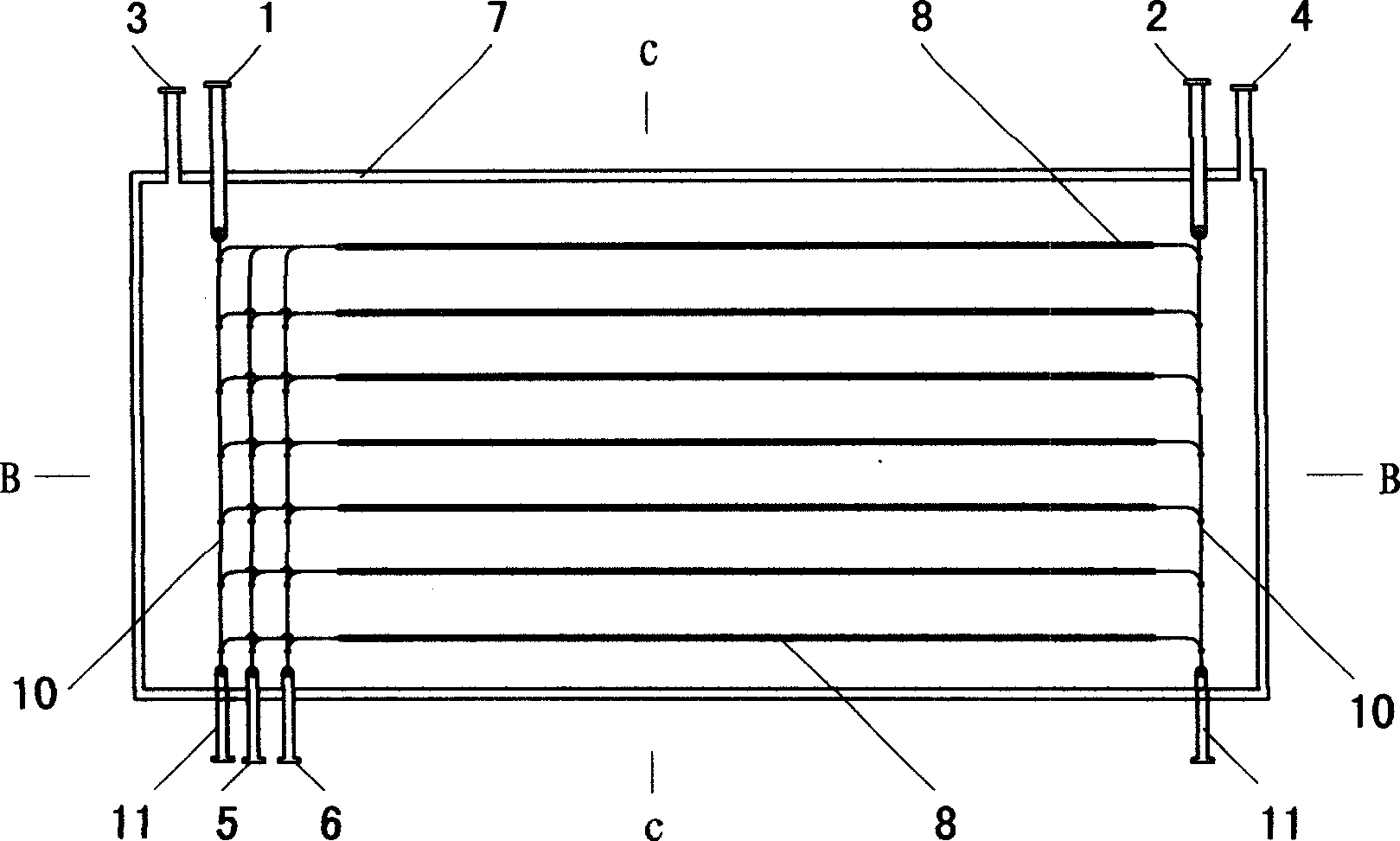

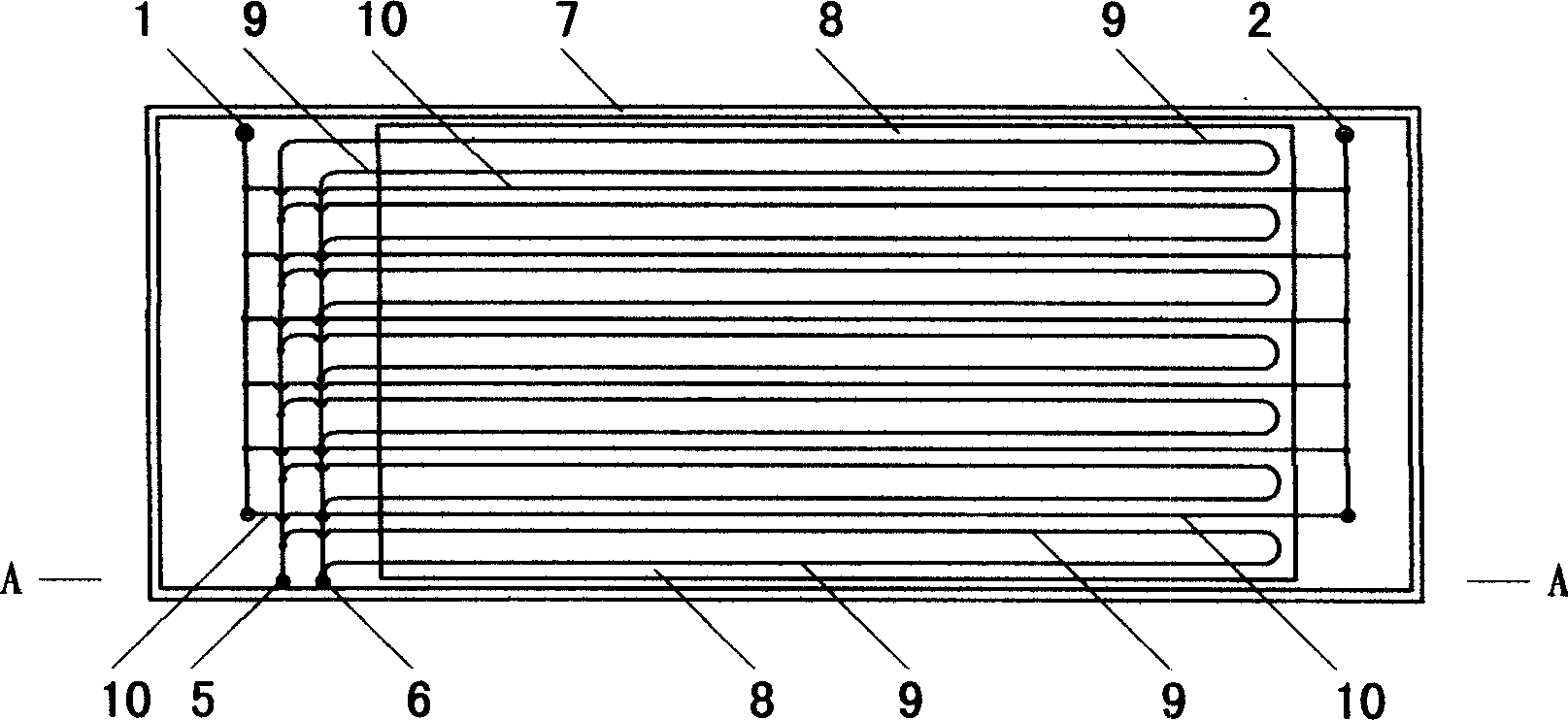

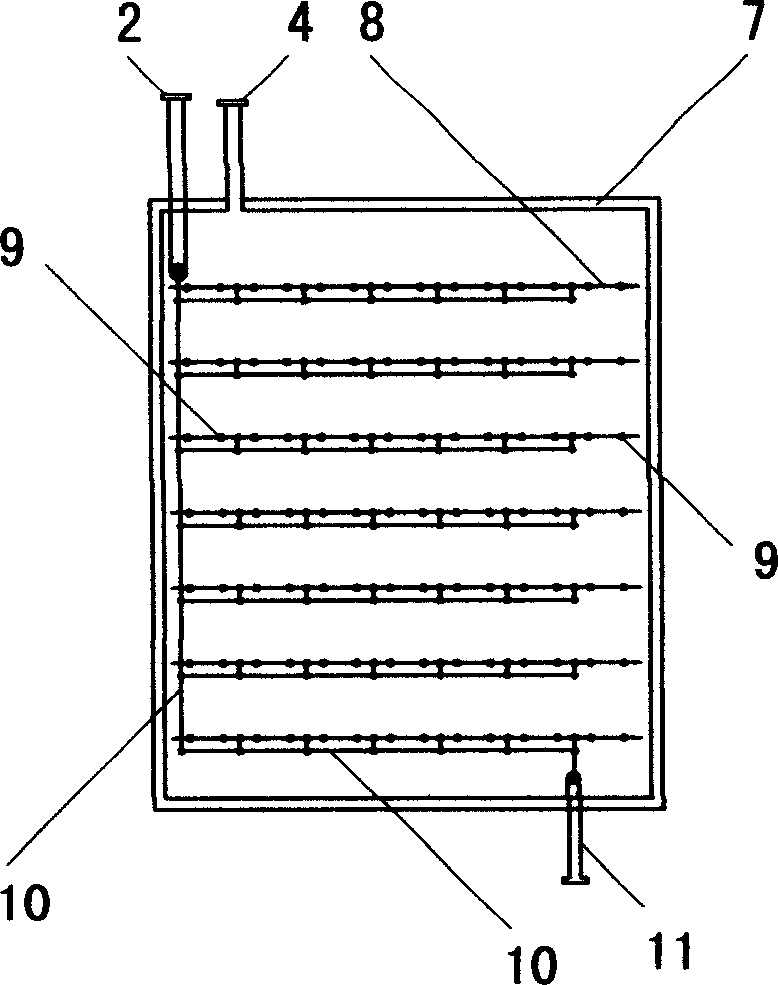

[0023] Such as Figure 4 The shown is a plate-type ice storage tank system in which indirect ice melting and direct ice melting coexist, and the indirect ice melting channel drainage type ice storage tank system mainly includes:

[0024] 1) Refrigerant or brine circuit: the outlet of the refrigerator 20 is connected to the ice storage tank 12 with plate-type indirect ice-melting and direct ice-melting through the inlet 6 of the refrigeration coil, and the plate-type ice storage with both indirect ice-melting and direct ice-melting The tank 12 is connected to the refrigerator 20 through the outlet 5 of the refrigeration coil.

[0025] 2) Air-conditioning water circuit: The water outlet of the refrigeration pump 18 is divided into two channels, one of which is connected to the plate-type ice storage tank 12 where indirect ice melting and direct ice melting coexist through the indirect ice melting inlet valve 19, the indirect ice melting coil inlet 1, and then through the The indi...

specific Embodiment approach 3

[0030] Such as Figure 5 The shown is a plate-type indirect ice-melting and direct ice-melting ice-storage tank system implemented by an indirect ice-melting channel brine type ice-storage tank system, which mainly includes:

[0031] 1) Refrigerant or brine circuit: the outlet of the refrigerator 20 is connected to the ice storage tank 12 with plate-type indirect ice-melting and direct ice-melting through the inlet 6 of the refrigeration coil, and the plate-type ice storage with both indirect ice-melting and direct ice-melting The tank 12 is connected to the refrigerator 20 through the outlet 5 of the refrigeration coil.

[0032] 2) The refrigerant circuit of the indirect ice-melting channel of the air conditioner: the outlet of the refrigeration pump 18 is connected to the ice storage tank 12 of the plate-type indirect ice-melting and direct ice-melting through the inlet 1 of the indirect ice-melting coil, and the plate-type indirect ice-melting and direct ice-melting coexist...

specific Embodiment approach 4

[0037] Such as Figure 6 The shown is a plate-type ice storage tank system in which indirect ice melting and direct ice melting coexist, and the indirect ice melting channel refrigerant heat exchange type ice storage tank system mainly includes:

[0038] 1) Refrigerant or brine circuit: the outlet of the refrigerator 20 is connected to the ice storage tank 12 with plate-type indirect ice-melting and direct ice-melting through the inlet 6 of the refrigeration coil, and the plate-type ice storage with both indirect ice-melting and direct ice-melting The tank 12 is connected to the refrigerator 20 through the outlet 5 of the refrigeration coil.

[0039] 2) Air-conditioning water circuit: The outlet of the refrigeration pump 18 is divided into two circuits, one of which is connected to the water-side inlet of the heat exchanger 17 through the indirect ice-melting inlet valve 19, and the water-side outlet of the heat exchanger 17 is connected to the air-conditioning terminal 13 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com