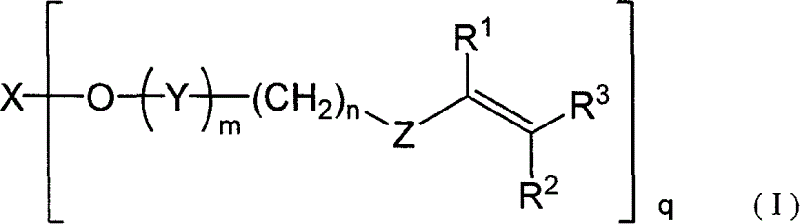

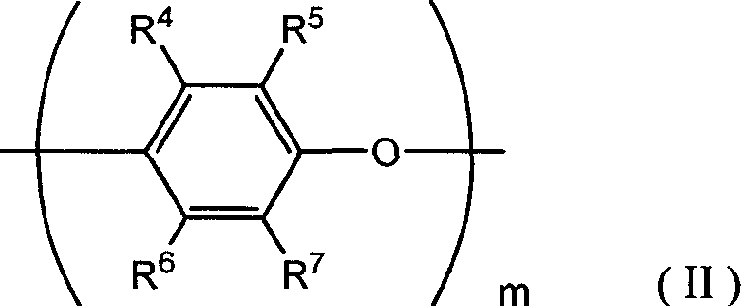

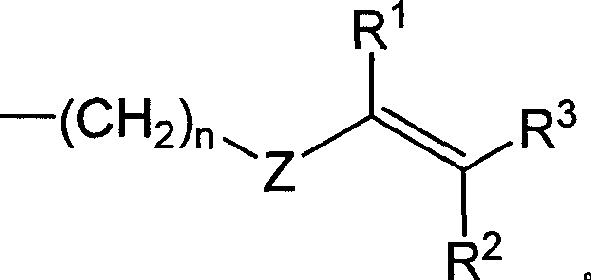

Poly(phenylene ether) resin composition, prepreg, and laminated sheet

A technology of polyphenylene ether resin and prepreg, which is applied in the field of laminates and can solve problems such as difficulty in production, decreased heat resistance of laminates, and reduced relative content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] Preparation of Low Molecular Weight PPE (PPE-1)

[0070] First, adjust the molecular weight of PPE.

[0071]Prepare and mix 36 parts by mass of PPE (Japan GE Plastics Co., Ltd., trade name "Noryl PX9701", number average molecular weight 14,000), 1.54 parts by mass of 2,6-xylenol as phenols, 1.06 parts by mass of tert-butylperoxyisopropyl monocarbonate (NOF Corporation, trade name "Perbutyl I"), and 0.0015 parts by mass of cobalt naphthenate. To this mixture was added 90 parts by mass of toluene as a solvent, and the mixture obtained above was stirred at 80°C for 1 hour to disperse or dissolve the components. After the reaction was completed, the prepared PPE was reprecipitated by adding a large amount of methanol, and after removing impurities, it was dried at 80° C. under reduced pressure for 3 hours to completely remove the solvent. The number average molecular weight of the PPE obtained after this step was determined to be about 2,400 by gel permeation chromatograp...

Embodiment 1

[0085] 70 parts by mass of vinylbenzene methylated low molecular weight PPE ("PPE-1") and 100 parts by mass of toluene as a solvent were mixed and stirred at 80°C for 30 minutes until completely dissolved. In the PPE solution obtained, add 30 mass parts of TAIC (Japan Chemical Industry Co., Ltd.) as a crosslinking curing agent, 20 mass parts of brominated organic compound decabromodiphenylethane (Albemarle Asano company, trade name " SAYTEX 8010 ", bromine content: 82wt%) as a flame retardant, and 2.5 parts by mass of α, α'-bis(tert-butylperoxym-isopropyl)benzene (NOF Corporation, trade name "Perbutyl P") ) as an initiator. Further, 14 parts by mass of spherical silica (Denki Kagaku Kogyo Co., Ltd., trade name "FB3SDC") was added as an inorganic filler, and then the above mixture was mixed, dispersed and dissolved in a solvent (toluene) to obtain a resin composition, namely varnish. Since the flame retardant is a brominated organic compound that does not react with PPE and T...

Embodiment 2~9

[0092] Using the components in the compositions shown in Table 1 and Table 2, prepregs and samples (i) to (v) were prepared in a similar manner to Example 1. Incidentally, the unmodified PPE with a number average molecular weight of about 9,000 added in Example 9 was obtained from the above-mentioned PPE with a number average molecular weight of 14,000 (Japan GE Plastics Co., Ltd., trade name "Noryl PX9701") by molecular cutting technology. prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com