Organic waste gas purifying processing device

A technology for purification and treatment of organic waste gas, applied in the field of organic waste gas purification and treatment devices, can solve the problems of prominent energy consumption and high operating costs of purification equipment, affecting the promotion and application of the process, and low process efficiency, and achieving a small footprint, Simple structure and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

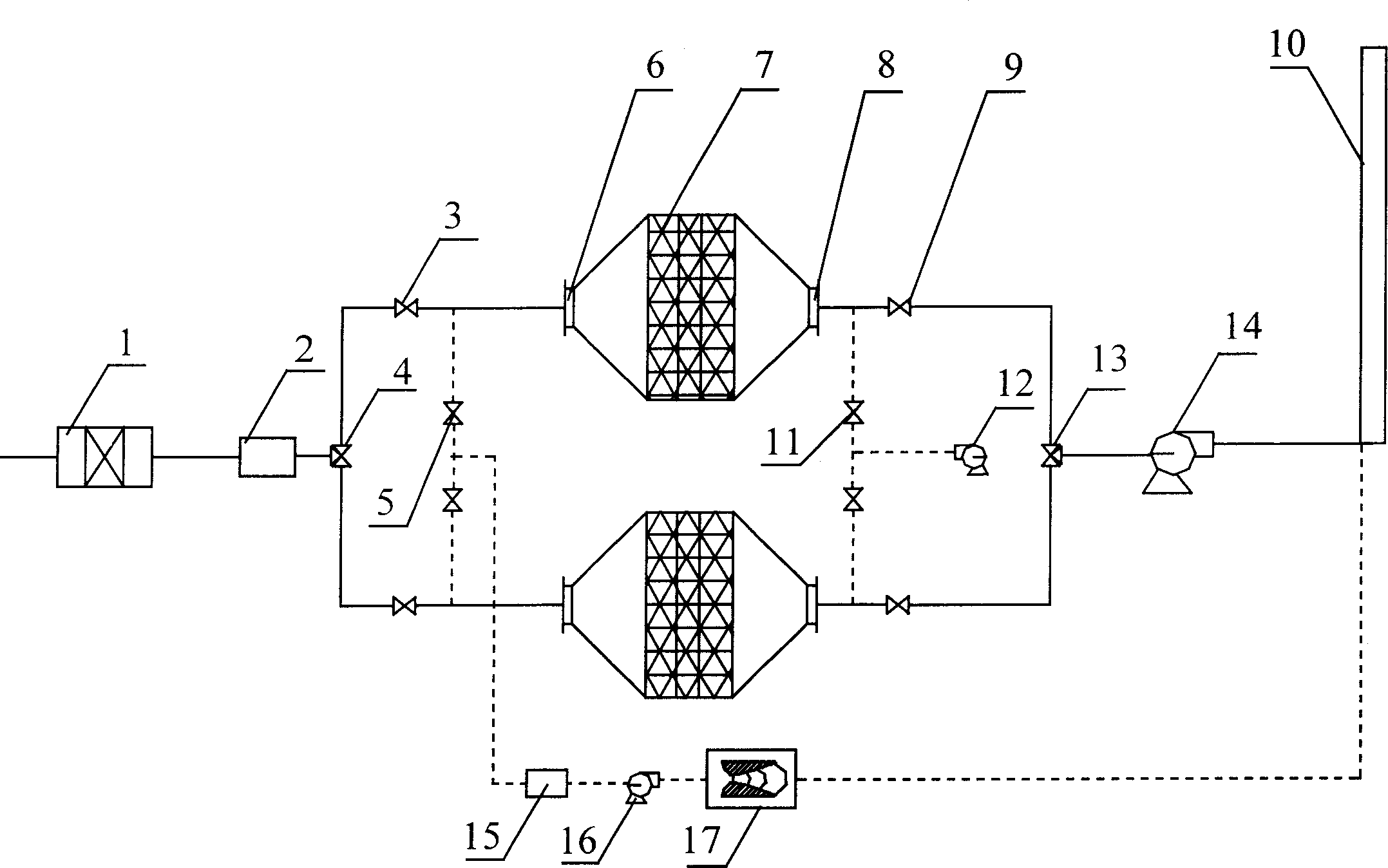

[0010] Specific embodiments of the present invention will be described in detail with reference to the above-mentioned drawings. figure 1 A purification treatment device for organic waste gas is given, which is composed of adsorption, desorption components and purification components. The suction and desorption components include a filter 1 and a flame arrester 2 connected in sequence. The outlet of the flame arrester 2 passes through a three-way valve 4 and is connected to the inlet 6 of two adsorbers 7 at the same time. The inlet 6 of each adsorber 7 is connected to the three-way valve. Each of the through valves 4 is provided with a valve 3, and the valve 3 is used to control the switch of the pipeline between the flame arrester 2 and the inlet 6 of the adsorber 7. The outlet 8 of each adsorber 7 is connected to the three-way valve 13 after passing through a valve 9, and the three-way valve 13 is connected to the exhaust cylinder 10 after absorbing the main fan 14, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com