Fabrication method of field emitter electrode

An emitter electrode, manufacturing field technology, applied in electrode system manufacturing, discharge tube/lamp manufacturing, cold cathode manufacturing, etc., can solve problems such as low mechanical shock resistance and poor adhesion strength of carbon nanotubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

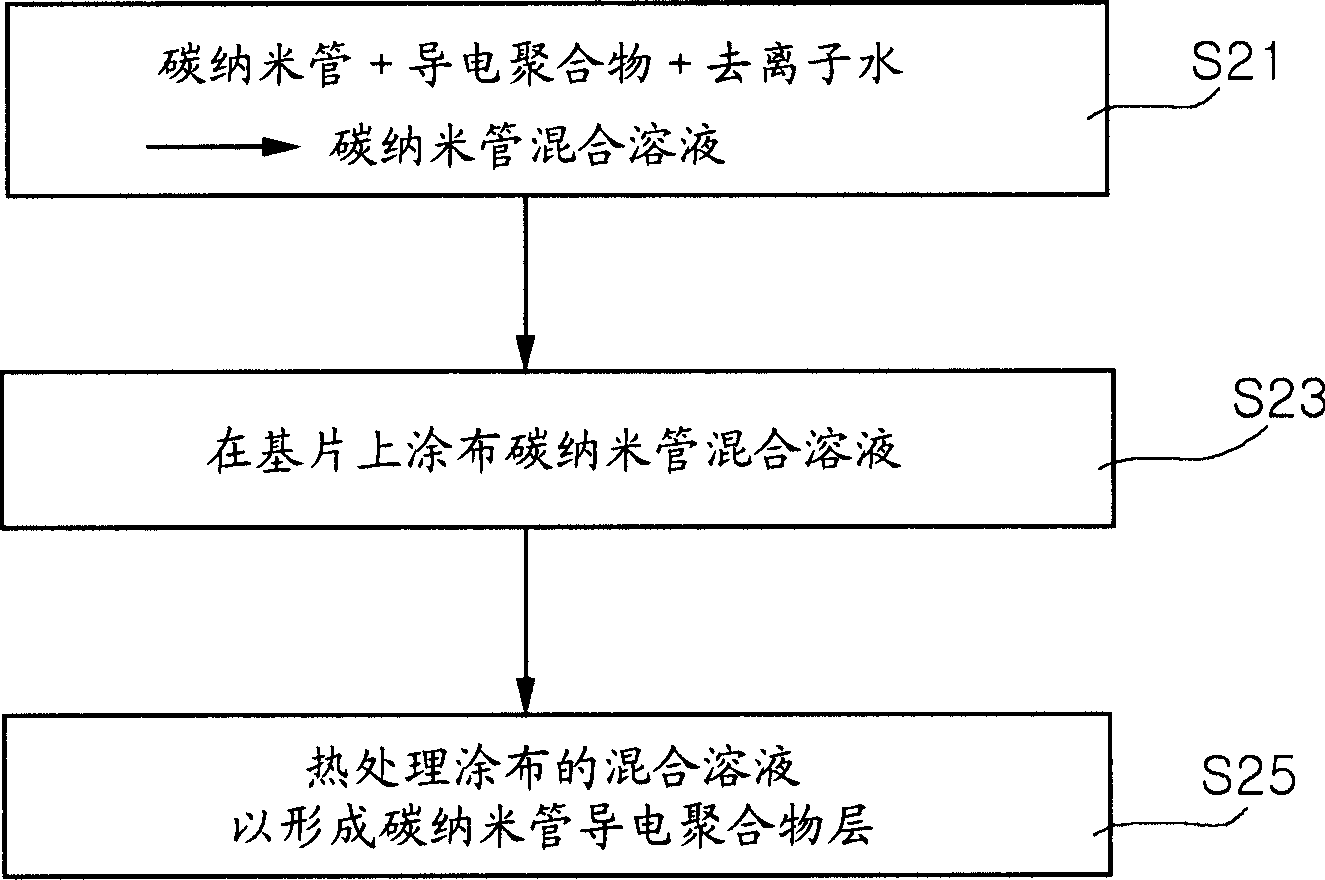

[0036]First, in order to prepare the carbon nanotube mixture according to the present invention, 3 grams of poly(3,4-ethylenedioxythiophene) (Baytron P, Bayer) as a conductive polymer were weighed out, and 15 milligrams (mg) were passed through chemical vapor Multi-walled carbon nanotubes prepared by phase deposition (CVD). The conductive polymer and carbon nanotubes were mixed in 97 grams (g) of deionized water to prepare the desired carbon nanotube mixture. In order to improve the adhesive strength of the substrate, 4 grams of isopropanol, 1.5 grams of ethylene glycol, 1.2 grams of tetraethoxysilane, and 1 gram of acetic acid (100%) were added to the carbon nanotube mixture, and an additional 30 mg was added as A dispersant of benzalkonium chloride (BKC) was added to the CNT mixture. The viscosity of the carbon nanotube mixture was measured to be about 90 cps.

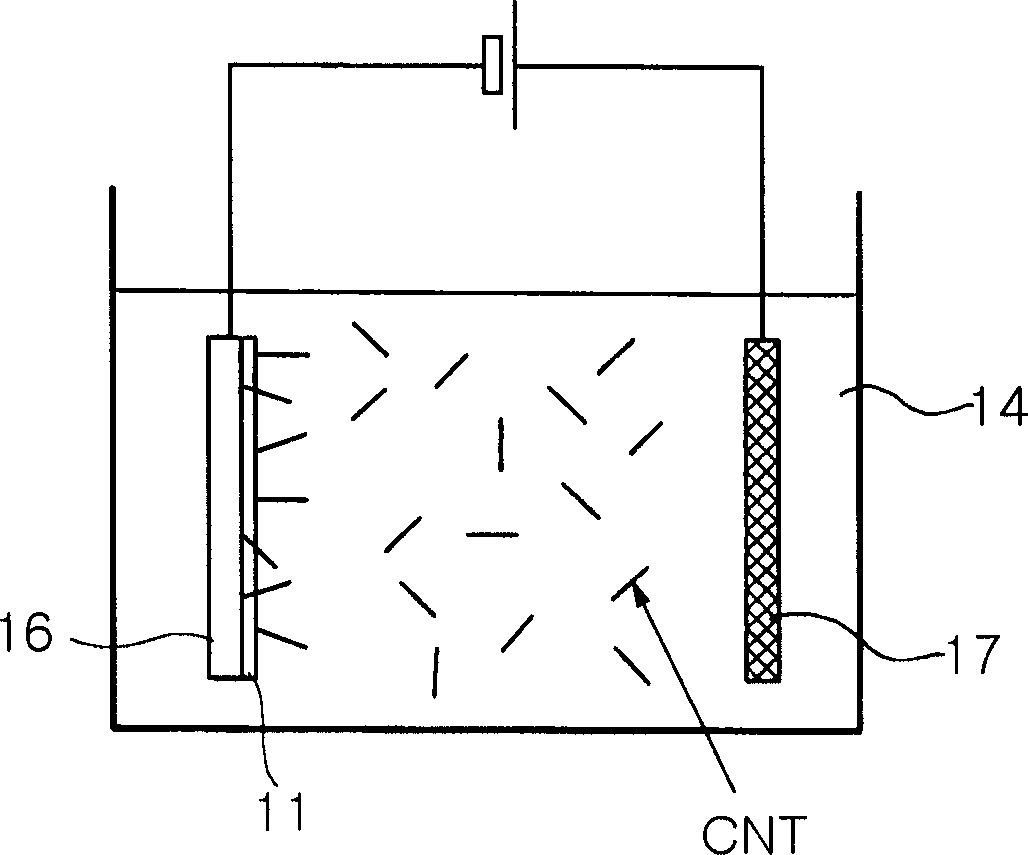

[0037] In this example, in order to achieve uniform dispersion of carbon nanotubes, the carbon nanotube mixture ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com