System for continuous batch preparing diamond film

A technology of diamond film and preparation system, which is applied in metal material coating process, gaseous chemical plating, coating, etc., and can solve the problems such as the reduction of diamond film preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

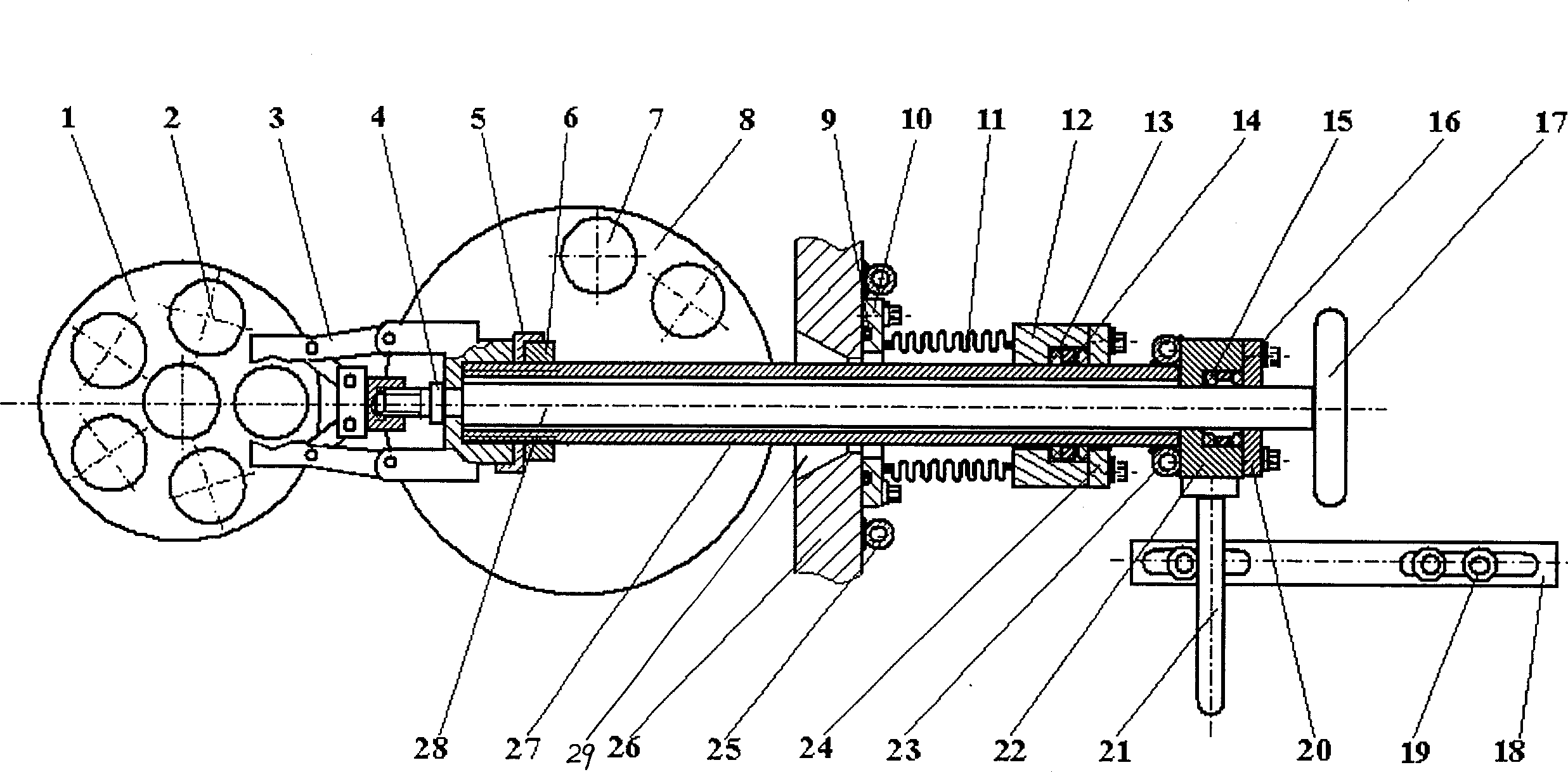

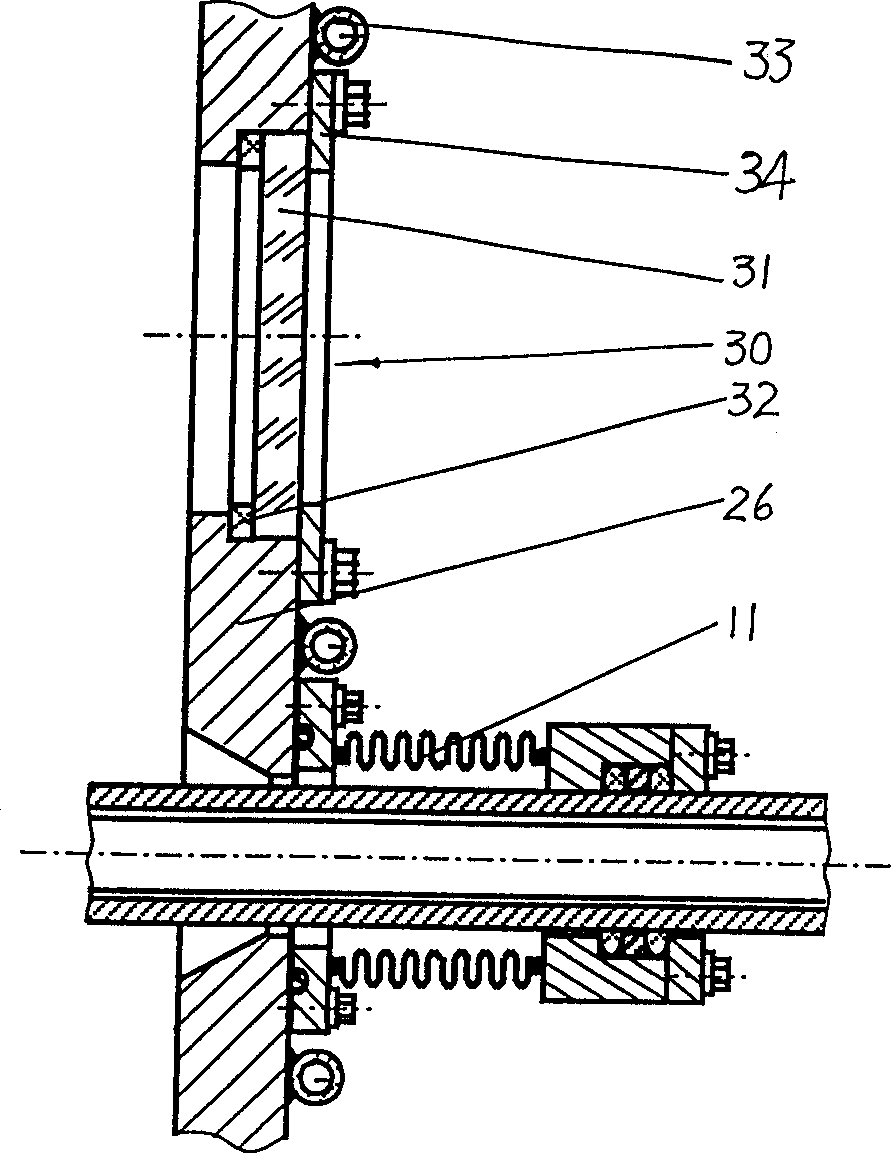

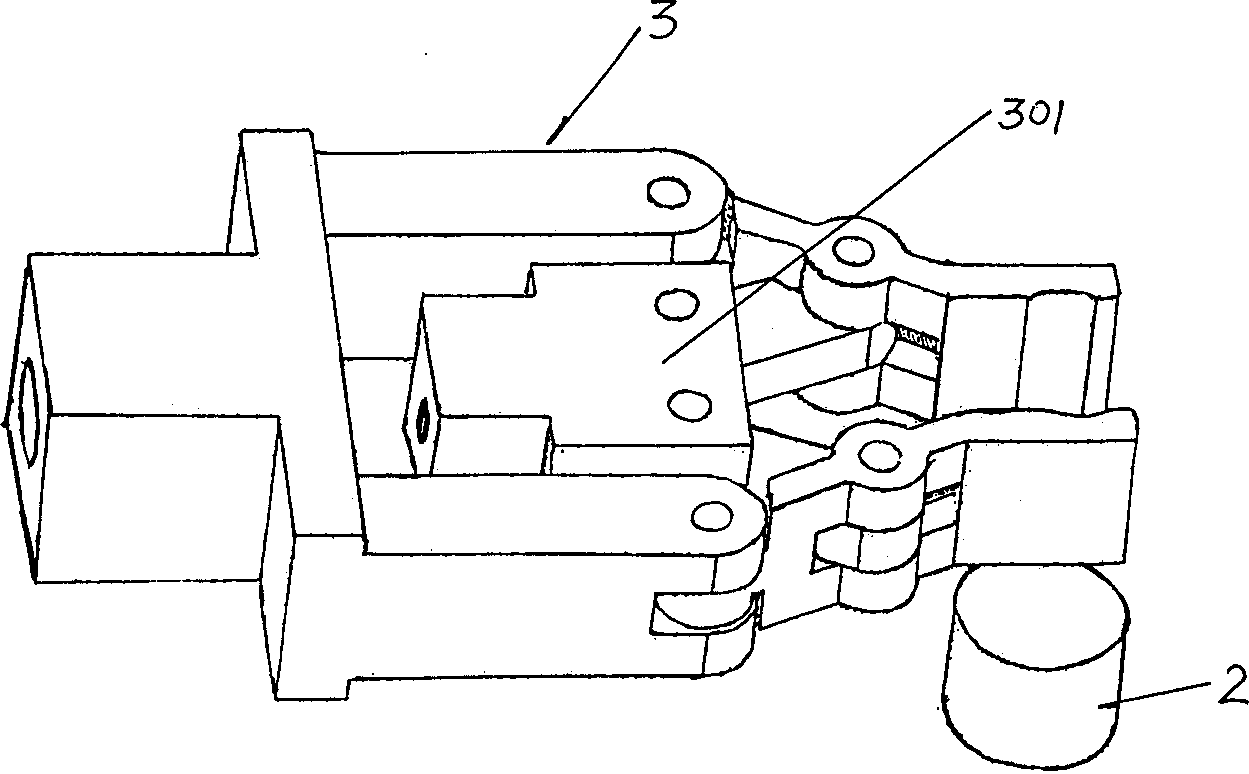

[0030] Such as figure 1 , 2 , 3 shown.

[0031] figure 1 Schematic diagram of the continuous preparation system for CVD diamond films. In the figure, the substrate 2 on which the diamond film is deposited is placed on the substrate water-cooled workbench 1, and the substrate 7 to be deposited is placed on the substrate warehouse 8 that can be rotated at a certain angle. The substrate 7 to be deposited on the platform is placed on the workbench 1, and the substrate on which the CVD diamond film deposition has been completed on the workbench 1 is taken back to the substrate warehouse 8. The substrate warehouse 8 can be used figure 1 The single-storey, single-layer structure shown can also be designed as a single-layer multi-storey structure according to needs. Each substrate storehouse rotates around the center under the drive of a conventional mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com