Rotor fluid mechanical transfiguration mechanism

A rotor fluid and mechanical technology, applied in the direction of rotary piston machinery, mechanical equipment, machine/engine, etc., can solve the problems that the blades cannot be tightly attached, cannot form a closed volume, and have poor sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

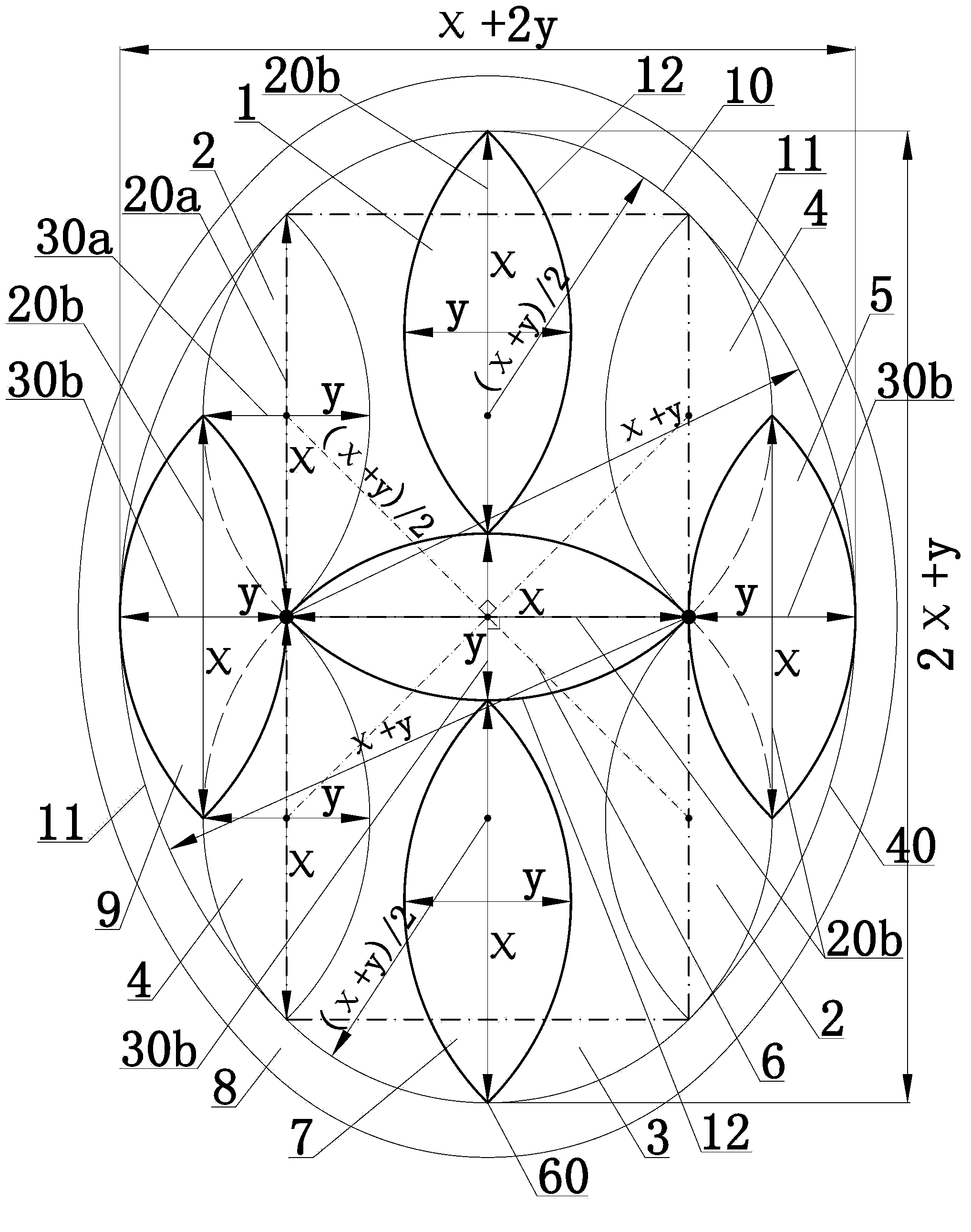

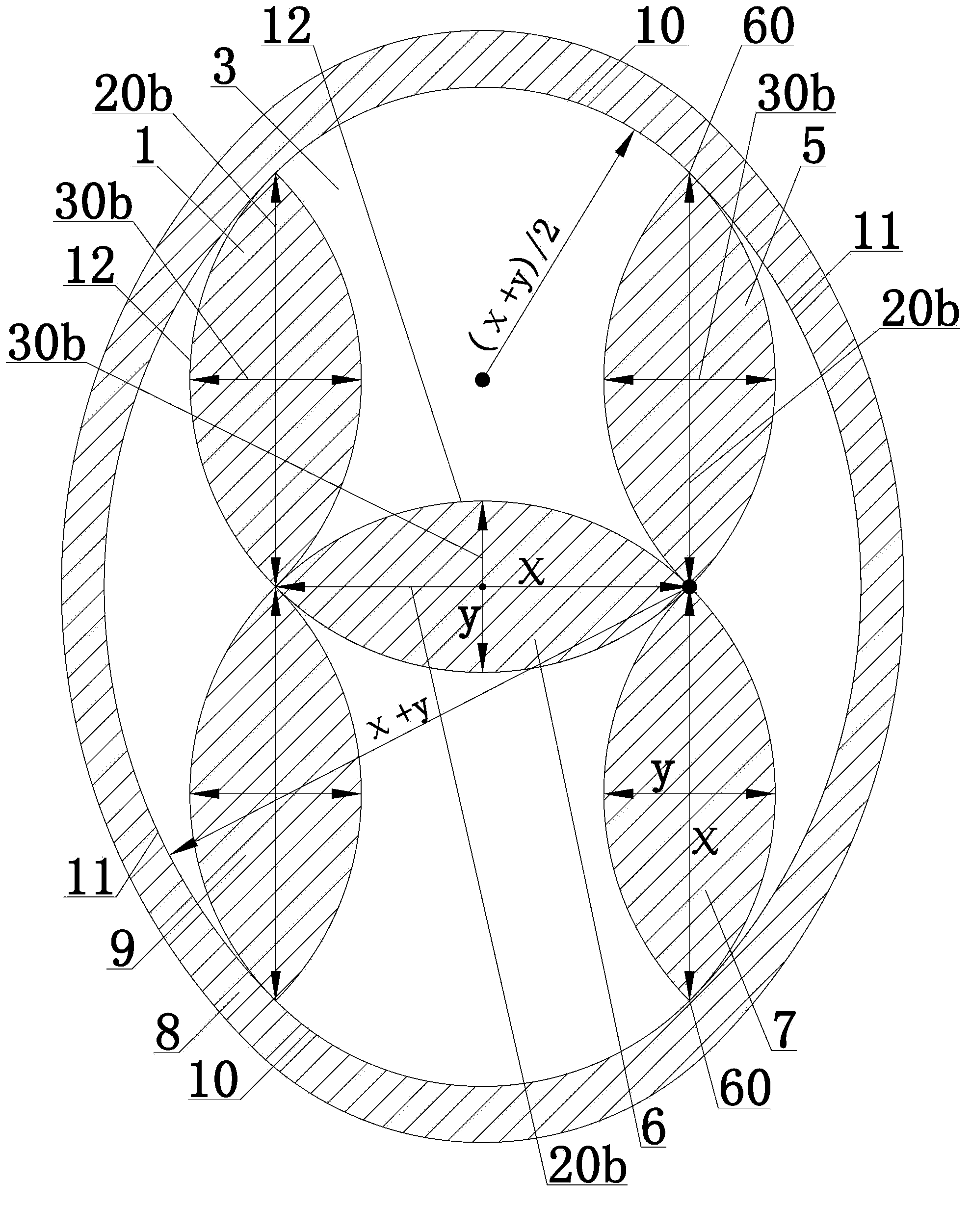

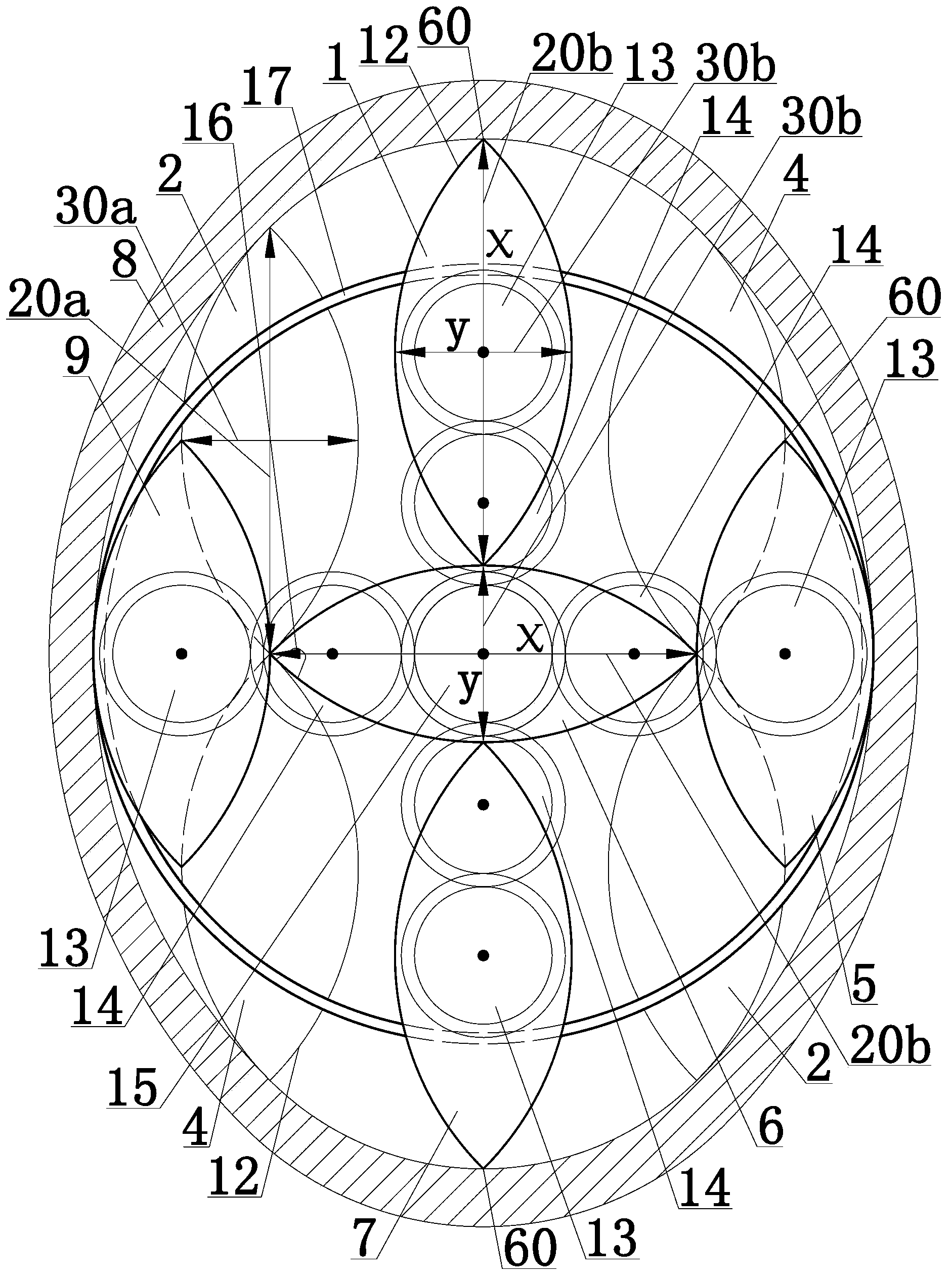

[0035] A rotor fluid mechanical displacement mechanism, comprising a casing (8) and a rotating shaft (18), a chamber (3) and a planetary gear train transmission mechanism are arranged in the casing (8), and the chamber (3) is in the shape of an ellipse The contour line of the shaped cross-section consists of a pair of mirror images with equal length, an arc of 90° and a radius of The small arc line segment (10) and a pair of mirror symmetry are equal in length, the arc is 90° and the radius is The large arc line segment (11) is correspondingly connected to form, and the two ends of a small arc line segment (10) are respectively connected tangentially with each end of the two large arc line segments (11), and the two ends of the other small arc line segment (10) are respectively It is connected tangentially with each other end of the two large circular arc segments (11), and the length of the central major axis of the chamber (3) is a sub-elliptical cross-section. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com