Method for producing resist substrates

A technology of resist and resist layer, which is applied in the field of preparing substrates, can solve the problems of time-consuming and increased processing time, and achieve the effects of large beam width, reduced exposure time, and excellent separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

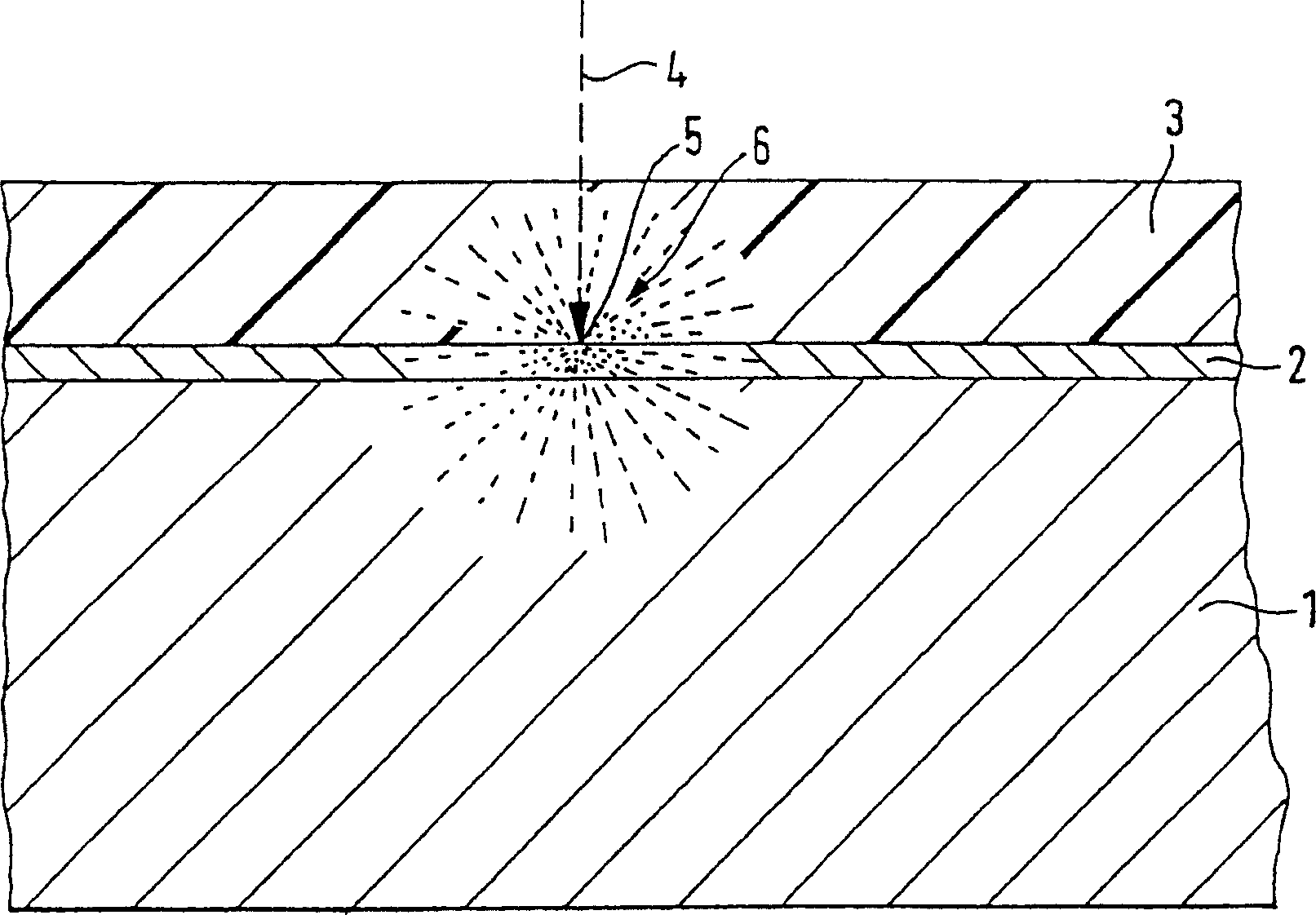

[0041] Figure 1A is a cross-sectional view of a substrate 1 on which a conductive layer 2 made of a conductive material is coated. The conductive layer 2 can be produced, for example, from metals, metal alloys or conductive polymers. On the conductive layer 2 is located a resist layer 3 made of a negative resist. Since the negative resist 3 is generally non-conductive, the conductive layer 2 serves to redirect the electrons incident with the electron beam 4 . When the substrate 1 is sufficiently conductive, the conductive layer 2 can be discarded.

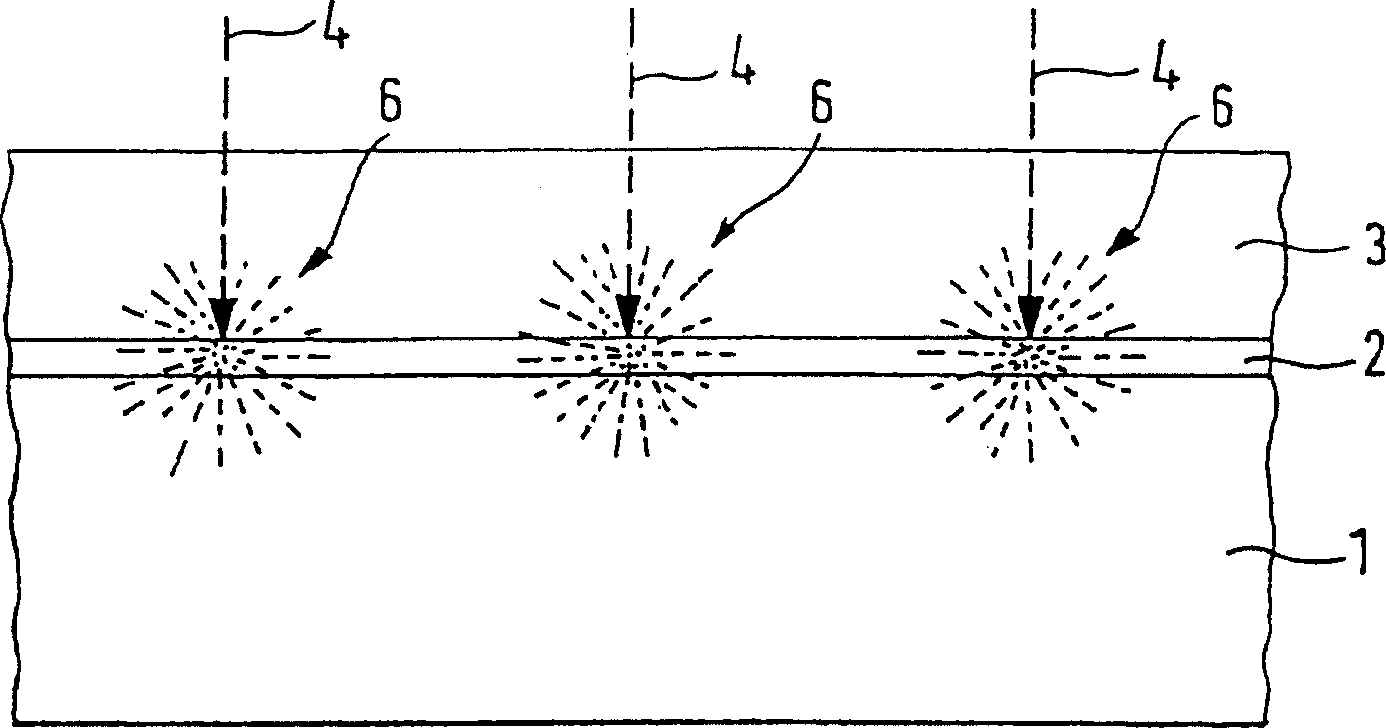

[0042] Since the conductive layer 2 scatters the primary electrons incident with the electron beam 4 and additionally emits secondary electrons by the conductive layer 2, an exposure region 6 is formed near the target region 5 hit by the electron beam 4, through which the adjacent target region 5 Areas of negative resist 3 are exposed. The range of the exposure area 6 is determined by the material used, the electron acceleratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com