Exposure apparatus, exposure method, and method for producing device

An exposure device and component technology, which is applied in semiconductor/solid-state device manufacturing, photolithography exposure device, microlithography exposure equipment, etc., can solve the problems of insufficient formation of liquid immersion area, vibration, liquid splash, etc. Occurrence of exposure blur and environmental changes in which substrates are placed, prevention of environmental changes, and effects of reliable recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

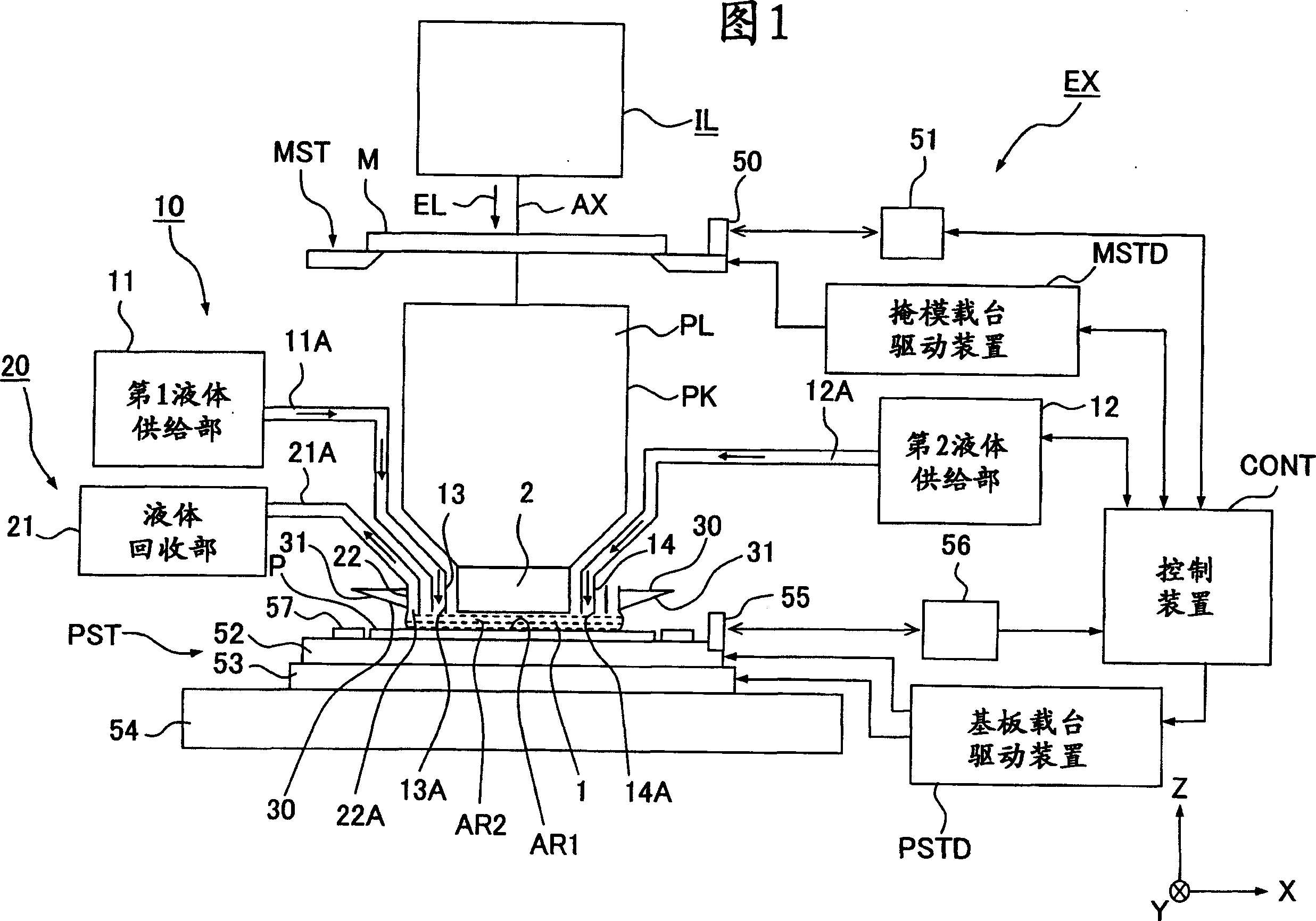

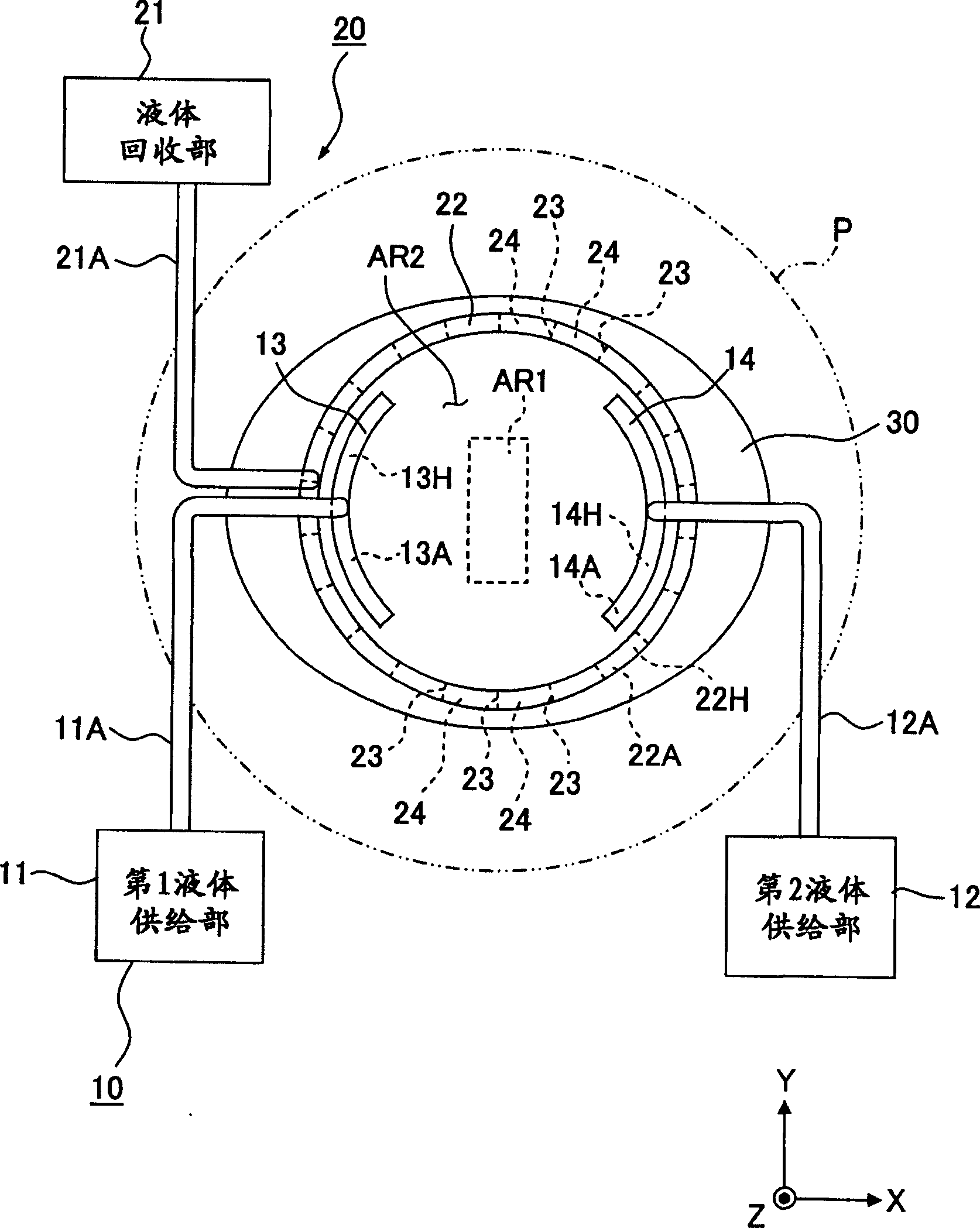

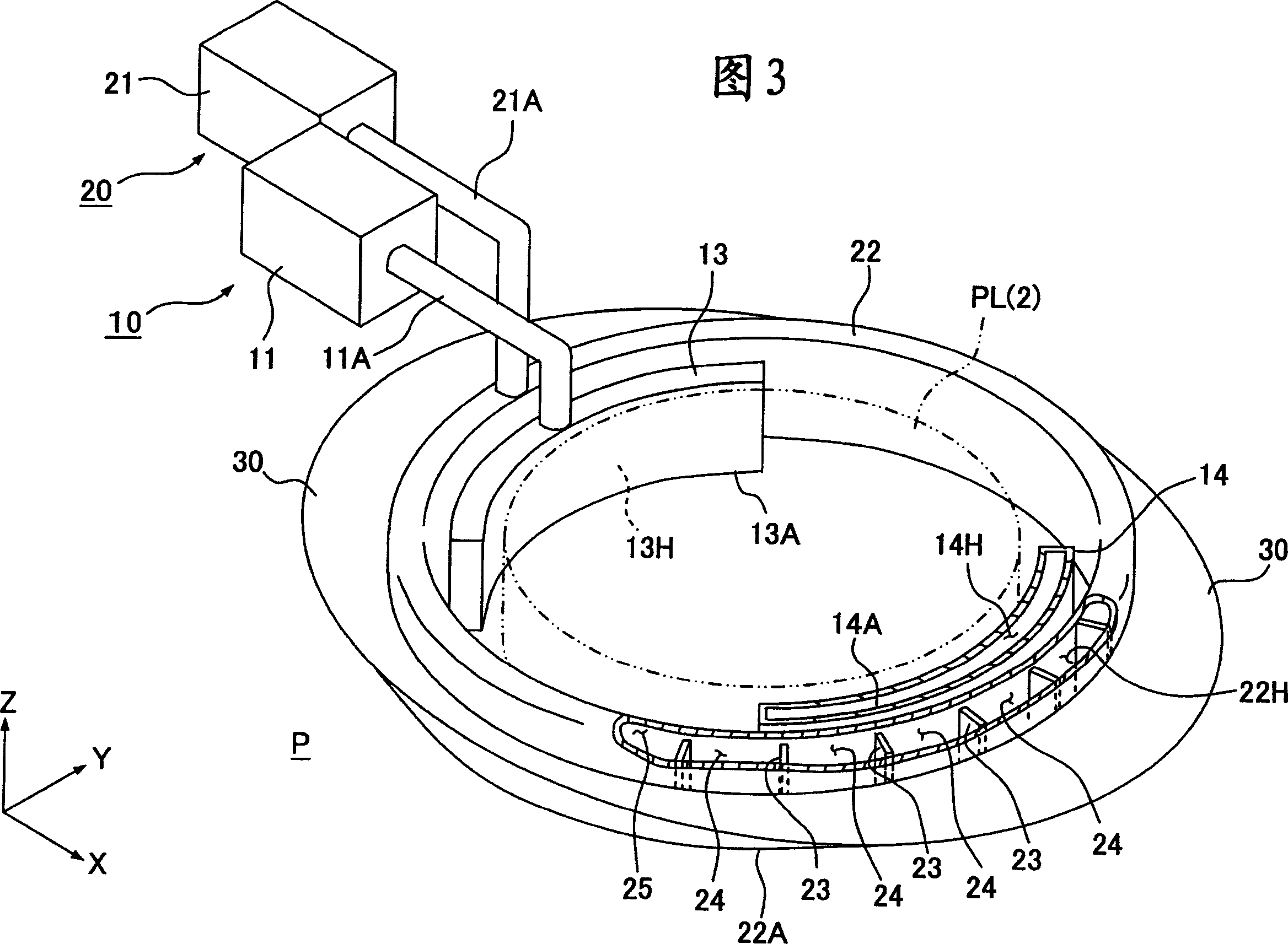

[0096] Hereinafter, the exposure apparatus of this invention is demonstrated with reference to drawings. FIG. 1 is a schematic configuration diagram showing an embodiment of an exposure apparatus of the present invention. In FIG. 1, the exposure apparatus EX includes: a mask stage MST supporting a mask M; a substrate stage PST supporting a substrate P; and an illumination optical system for illuminating the mask M supported by the mask stage MST with an exposure light beam EL. IL; the projection optical system PL for projecting and exposing the pattern image of the mask M illuminated by the exposure light beam EL onto the substrate P supported by the substrate stage PST; and the control device CONT for overall controlling the overall operation of the exposure device EX.

[0097] In addition, the exposure apparatus EX of this embodiment is a liquid immersion exposure apparatus to which a liquid immersion method is applied in order to substantially increase the depth of focus wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com