Plastic clad plate and its production method

A manufacturing method and composite board technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of plastic boards not being able to withstand gravity, low connection strength, high manufacturing cost, etc., and achieve beautiful appearance , light weight and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0088] Example 1, a plastic composite chair, such as Figure 20 , 21 As shown, it includes a base 8 , a leg frame 9 , a seat plate 10 , a backrest 11 and a connecting rod 12 .

[0089] The base 8 includes a base and five feet evenly and fixedly connected to the base, each foot is provided with a universal roller, so the base 8 can move.

[0090] The outrigger frame 9 is fixedly connected to the center of the base, and the outrigger frame 9 includes a sleeve, a sleeve rod slidingly sleeved in the sleeve, a lifting device arranged between the sleeve and the sleeve rod, and an adjusting rod for adjusting the lifting device. The lifting of the sleeve rod can be regulated by the adjusting rod, so as to achieve the purpose of adjusting the height of the outrigger frame 9 .

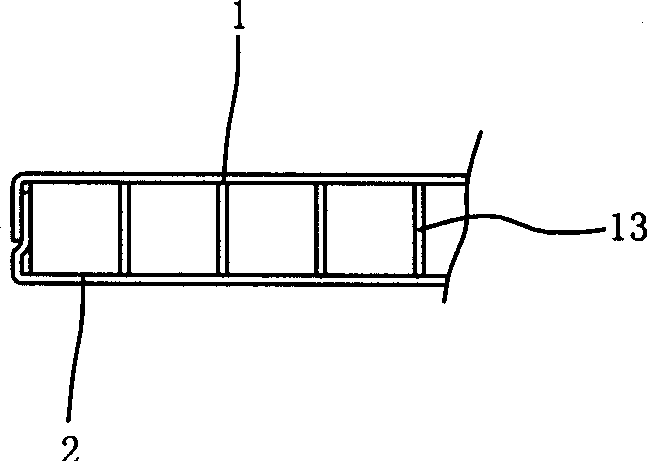

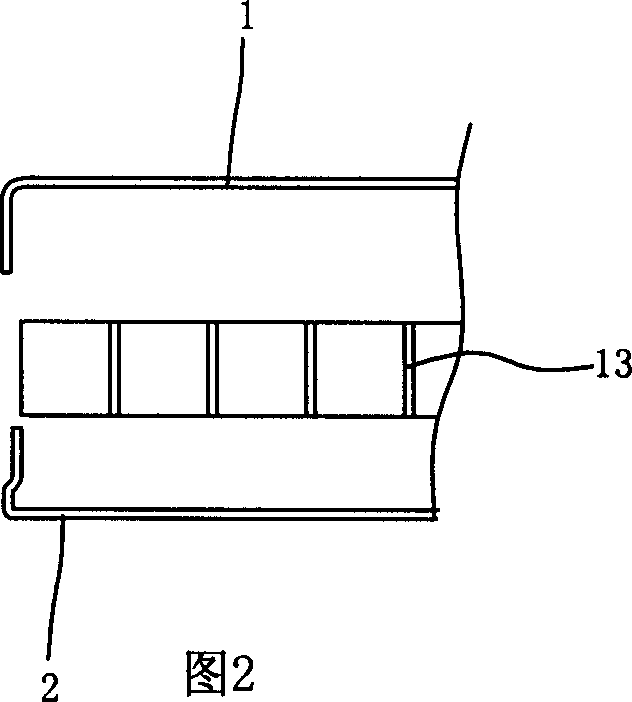

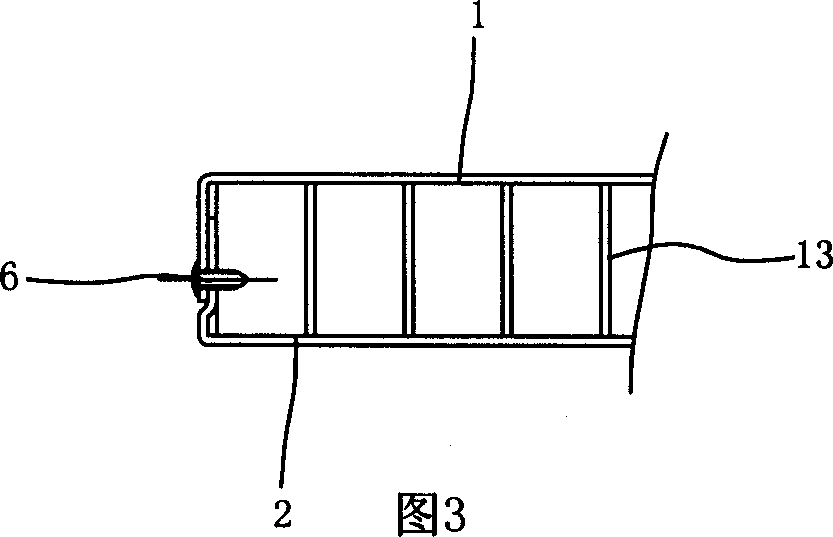

[0091]Early seat boards 10 and backrests 11 are made of bent wood boards or solid wood boards, which are heavy and waste wood. The structure of the seat board 10 and the backrest 11 of the present invention a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com