Method and apparatus for detecting leakage of liquid pressure pipeline

A technology for pipeline leakage, liquid pressure, applied in measuring devices, by detecting the appearance of fluid at the leak point, using liquid/vacuum for liquid tightness measurement, etc., can solve liquid pressure pipeline leakage, liquid pressure pipeline leak detection and positioning and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

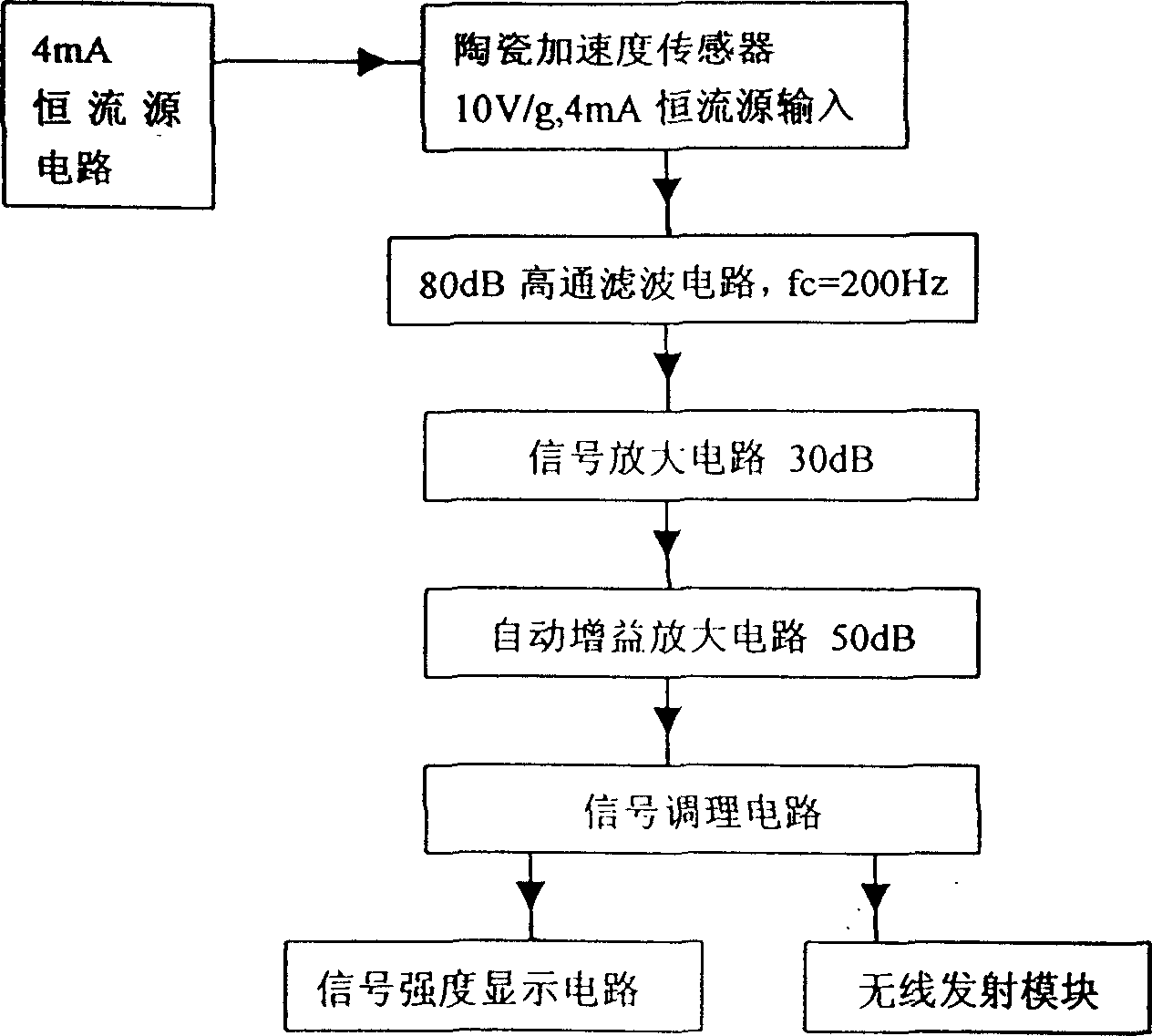

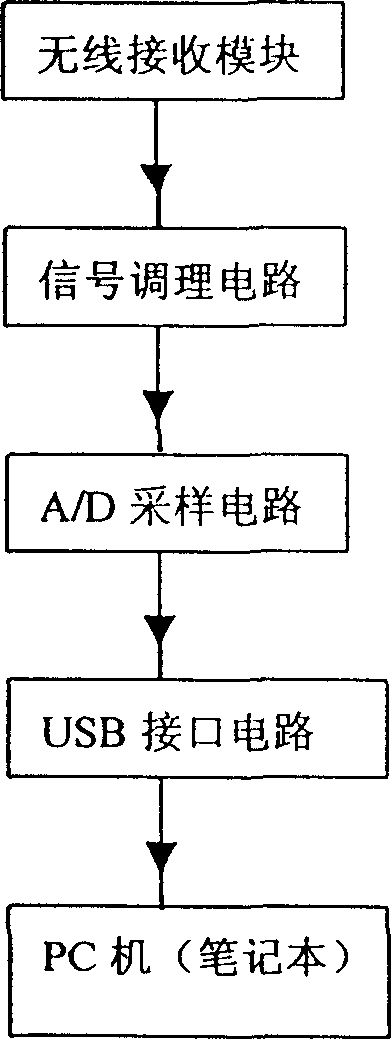

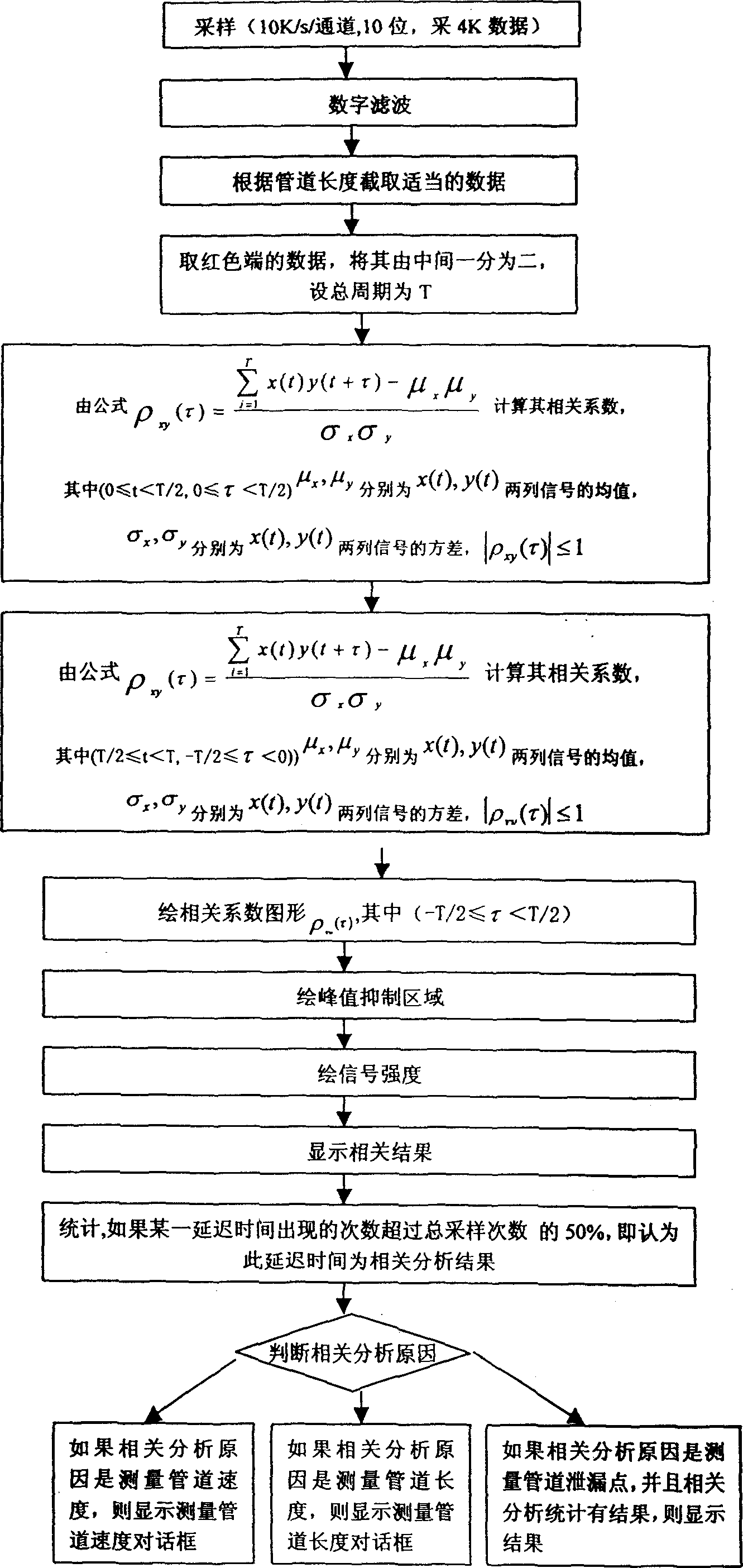

[0033] Detection method basic principle of the present invention is as follows:

[0034] When a pipeline leaks, it can generate sound pressure waves with a frequency much higher than that of ordinary water to propagate along the pipeline. The frequency of the leakage noise mainly depends on the size of the leak point, and the propagation speed of the leakage noise mainly depends on the diameter and material of the pipeline; Vibration sensors or acoustic emission sensors at both ends of the pipeline (the leakage point is surrounded by the middle) measure the leakage signal. Since the leakage point may be located in different positions of the pipeline, the time for the leakage sound to reach the two sensors is different. The correlation analysis of the two columns of signals is used. , generally the time difference between the leakage noise reaching the two sensors can be determined. According to the time difference, the distance between the leak point and the two sensors can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com