Robot overcurrent prevention system

An overcurrent and robot technology, applied in the field of robots, can solve the problems of robots stopping work and unstable posture, and achieve the effects of protecting the electrical system, eliminating noise, and reliably detecting overcurrent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

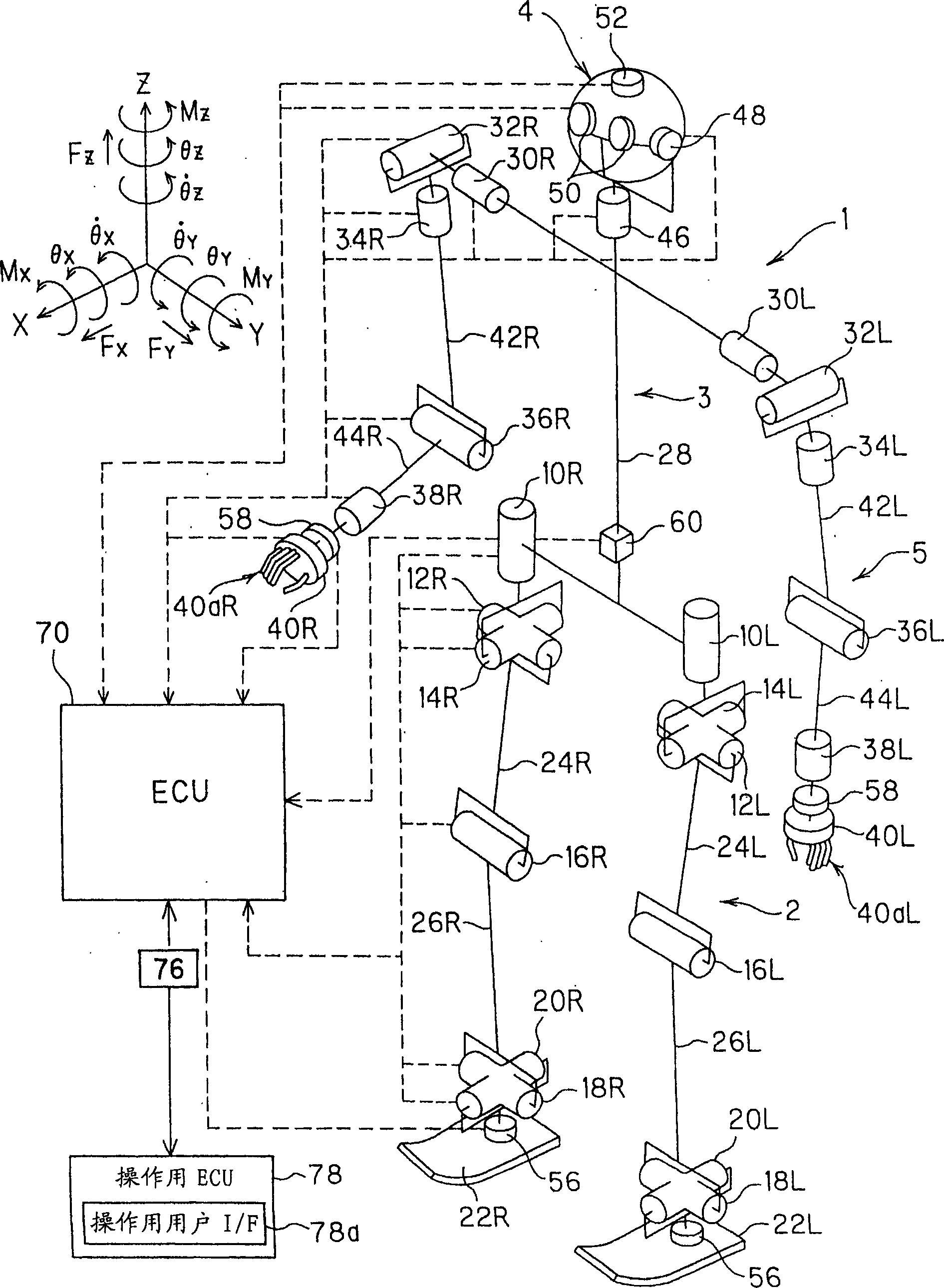

[0037] Next, an overcurrent prevention device for a robot according to a first embodiment of the present invention will be described with reference to the drawings.

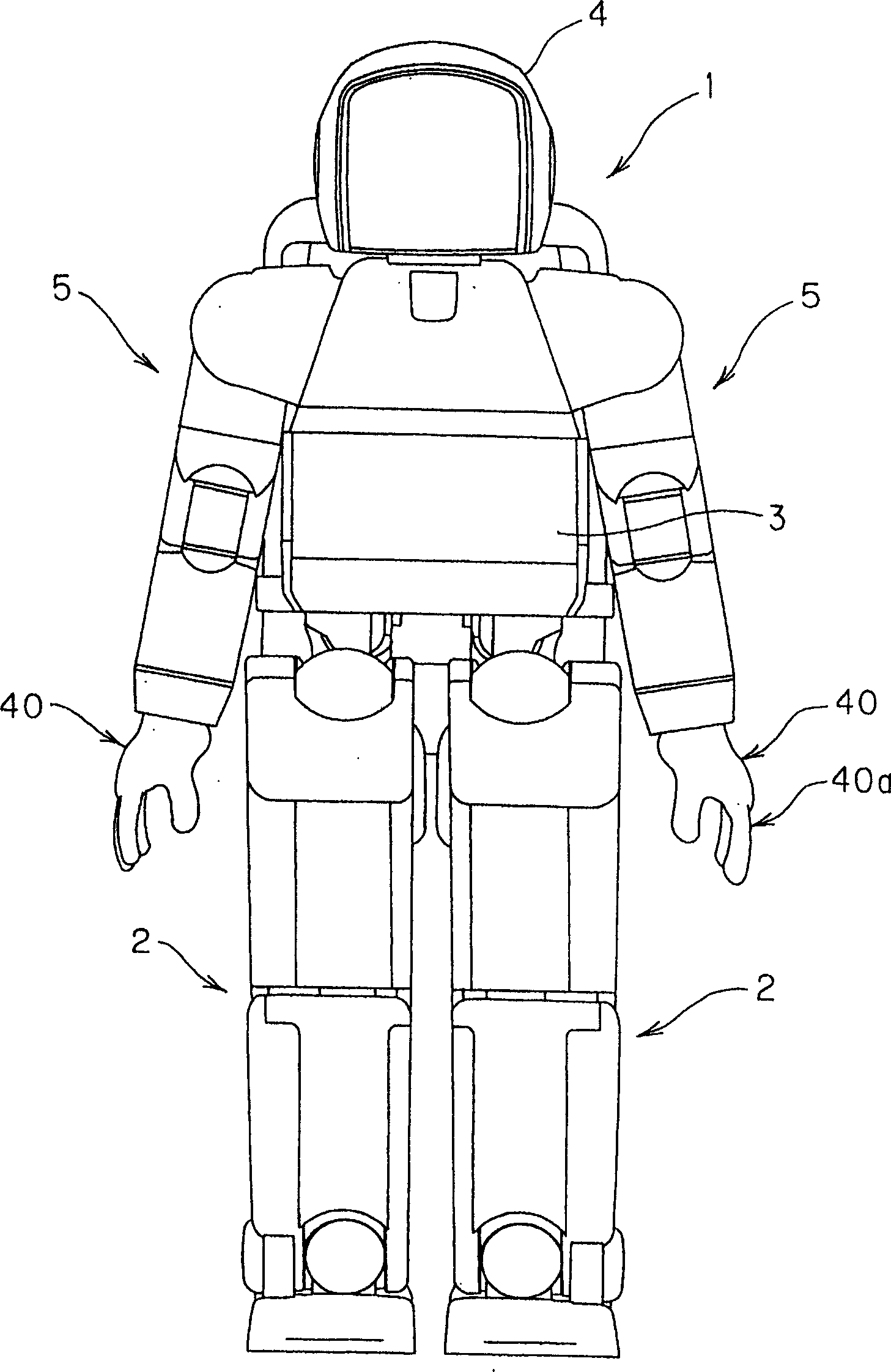

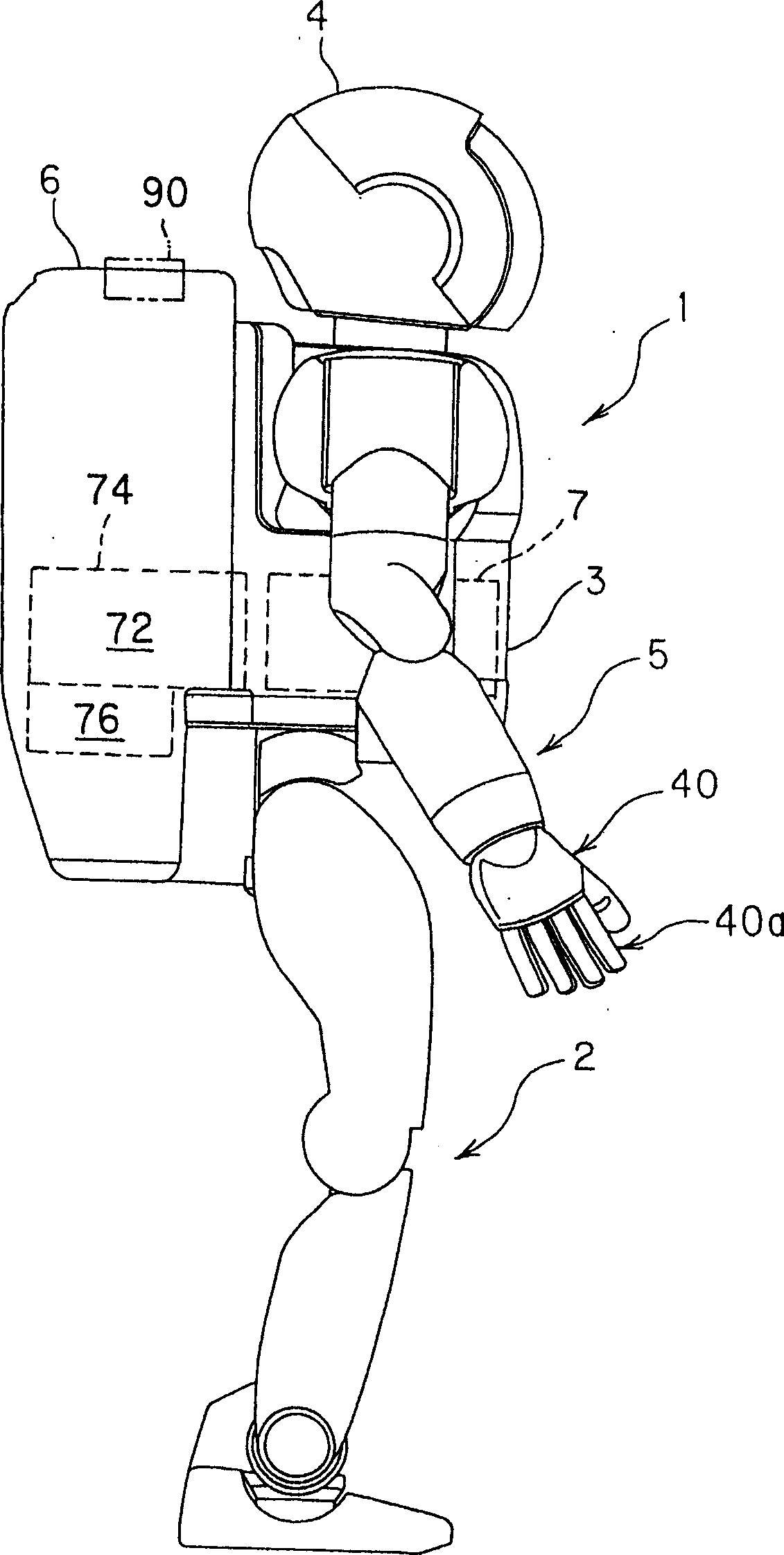

[0038] figure 1 It is a front view showing a robot as an object of the overcurrent prevention device of the first embodiment, figure 2is a side view of the robot. In addition, the robot is a legged mobile robot, and more specifically, there is, for example, a human-shaped legged mobile robot having two legs and two arms.

[0039] Such as figure 1 As shown, a robot (more specifically a legged mobile robot) 1 has multiple, more specifically two (bar) legs 2, and a base (upper body) 3 is provided above the legs 2. A head portion 4 is formed above the base body 3 , and two (bar) arm portions 5 are connected to both sides of the base body 3 . Additionally, if figure 2 As shown, a receiving portion 6 is provided on the back of the base body 3 . A battery (voltage source) 7 is housed inside the base body 3 , and...

Embodiment 2

[0088] Figure 11 represent the overcurrent prevention device of the second embodiment of the present invention and Figure 5 Same block diagram.

[0089] The description will focus on the difference from the first embodiment. In the second embodiment, a temperature sensor 90 is provided to detect the outside air temperature TA, the threshold value Va and the predetermined time T2 (first predetermined time) are changed according to the detected value, and the ECU 70 (more precisely, the CPU 70a) has an overcurrent prevention unit 70a4 that performs an overcurrent prevention operation using software technology.

[0090] Such as figure 2 As shown by the dotted line, in the second embodiment, the temperature sensor 90 is specifically arranged at an appropriate position facing the outside of the housing portion 6 to output a signal representing the external air temperature TA around the robot 1 . In addition, the same code|symbol is attached|subjected to the same member as 1st...

Embodiment 3

[0104] Figure 14 represent the overcurrent prevention device of the third embodiment of the present invention and Figure 6 Same block diagram.

[0105] The description will focus on the differences from the first and second embodiments. In the third embodiment, the structure of the first embodiment is used to realize a structure similar to that of the second embodiment. That is, separate from the ECU 70, the second ECU (ECU 2) 92 constituted by a single-chip microcomputer is installed near the temperature sensor 90 and connected by an appropriate cable (not shown), and the output TA of the temperature sensor 90 is input to the temperature sensor 90. To the 2nd ECU 92, the 2nd ECU 92 changes the value equivalent to the threshold value Va to be input to the one input terminal of the comparator 80c according to this input value.

[0106] More specifically, the output TA of the temperature sensor 90 is A / D converted and input to the second ECU 92, and the second ECU 92 follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com