Animal hair-like acrylic fiber having excellent processability

An acrylonitrile-based, fiber technology, applied in fiber type, fiber treatment, textile and papermaking, etc., can solve problems such as poor processability, and achieve the effect of improving hand feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

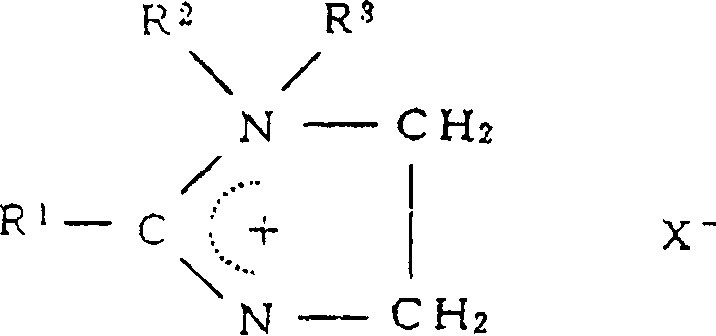

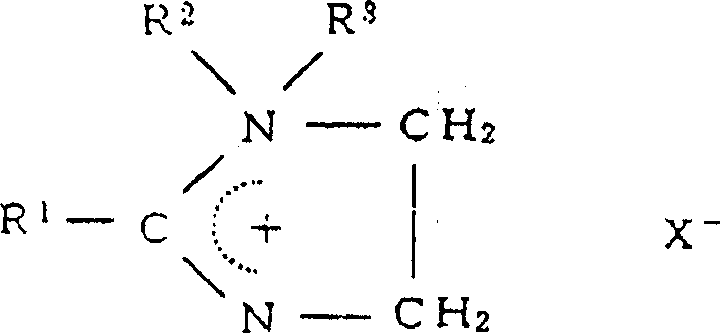

Method used

Image

Examples

Embodiment 1

[0074] A polymer obtained by copolymerizing 90% of acrylonitrile, 9.8% of methyl acrylate and 0.2% of sodium methallylsulfonate (intrinsic viscosity [η] in dimethylformamide at 30°C: 1.4) was dissolved in 50 % concentration of sodium thiocyanate aqueous solution, the production of polymer concentration of 12% of the spinning stock solution, the use of circular nozzle hole shape, the spinning in -3 ℃, 15% sodium thiocyanate aqueous solution The stock solution is spun, and washed, stretched, heat-treated, etc. are carried out according to conventional methods to prepare fiber tow.

[0075]Next, dilute the fiber treatment agent A described in Table 1 so that the total component concentration (total solid content) is 1.2% by weight, and after dipping the fiber tow in the diluted treatment agent, carry out tie-dyeing so that the adhesion amount of the treatment agent 50% relative to the dry weight of the fiber, then dried under hot air at 125°C for 15 minutes, cut into lengths rang...

Embodiment 2

[0078] Except having used the processing agent B-G for fibers described in Table 1, it carried out similarly to Example 1, and produced the fiber sample (2-7). These evaluation results are described together in Table 1.

[0079] It is clear from Table 2 that among fiber Nos. 1 to 4, 6 and 7 using the fiber treating agent used in the present invention, fiber Nos. 4 and 7 are excellent in both hand feeling and spinnability. Fiber No. 1, 2, 3 and 6 with slightly less amino-modified polyorganosiloxane had slightly poorer smoothness, and fiber No. 3 without added spinning oil had slightly poorer spinnability, but it could be used in used in practice. On the other hand, fiber No. 5 using a treatment agent that does not contain an imidazolium salt compound or a fatty amide contained a large amount of amino-modified polyorganosiloxane, and although it was excellent in smoothness, entanglement and the like occurred during spinning. Spinnability is poor.

Embodiment 3

[0081] A polymer obtained by copolymerizing 90% of acrylonitrile, 9.8% of methyl acrylate and 0.2% of sodium methallylsulfonate (intrinsic viscosity [η] in dimethylformamide at 30°C: 1.4) was dissolved in 50 % concentration of sodium thiocyanate aqueous solution, the production of polymer concentration of 12% of the spinning stock solution, the use of circular nozzle hole shape, the spinning in -3 ℃, 15% sodium thiocyanate aqueous solution The stock solution is spun, and washed, stretched, heat-treated, etc. are carried out according to conventional methods to prepare fiber tow.

[0082] Next, dilute the fiber treatment agent F described in Table 1 so that the total component concentration (total solid content) is 1.2% by weight, and after dipping the fiber tow in the diluted treatment agent, carry out tie-dyeing so that the adhesion amount of the treatment agent is relatively The dry weight of the fiber was 50%, followed by drying under hot air at 125° C. for 20 minutes, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com