Electric current sensing method and device based on polarization degree demodulating

A technology for sensing devices and polarization degrees, applied in measuring devices, measuring light polarization, measuring current/voltage, etc., can solve problems such as cost reduction and interference, achieve great flexibility, mature materials and components, and benefit Promoted app performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

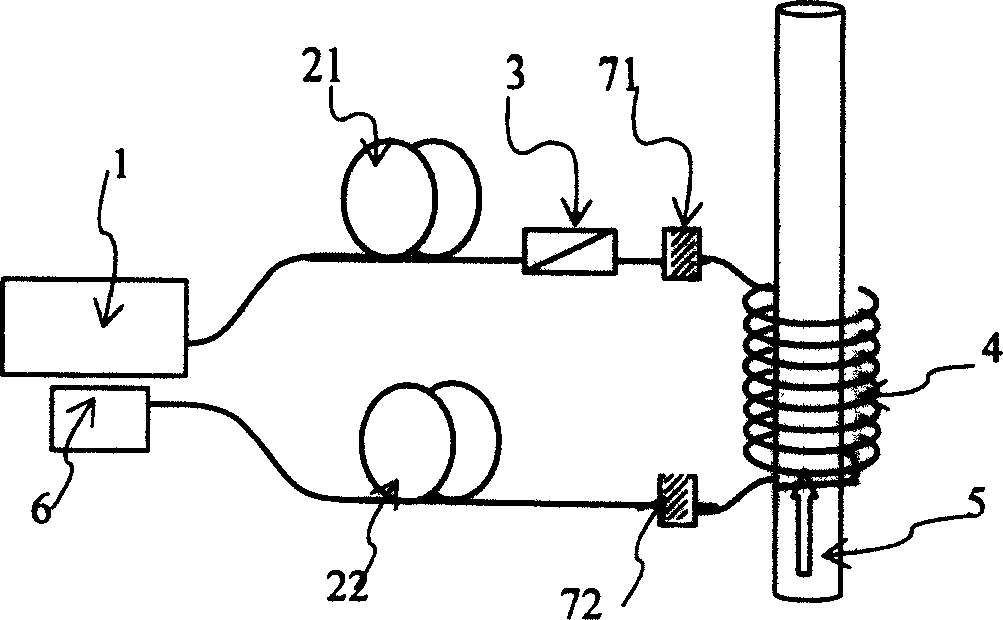

[0039] Embodiment 1: A scheme of using a fiber grating pair to form a fiber cavity, such as figure 2 shown. As can be seen from the figure, the current sensing device for demodulating the degree of polarization of the Faraday effect of the present invention is composed of an unpolarized light source 1, a first transmission fiber 21, a polarizer 3, a fiber cavity, and a second transmission fiber 22 connected in series in sequence. And light polarization analyzer 6 constitutes. Described optical fiber cavity is made of the first reflector 71, fiber ring 4, the second reflector 72 that are connected in series, and described fiber ring 4 is a multi-turn fiber ring that surrounds current cable 5 to be measured, and described first The reflectance values of the first reflector 71 and the second reflector 72 are greater than 0 and less than 1.

[0040] The first reflector 71 and the second reflector 72 are the first fiber Bragg grating 73 and the second fiber Bragg grating 74 re...

Embodiment 2

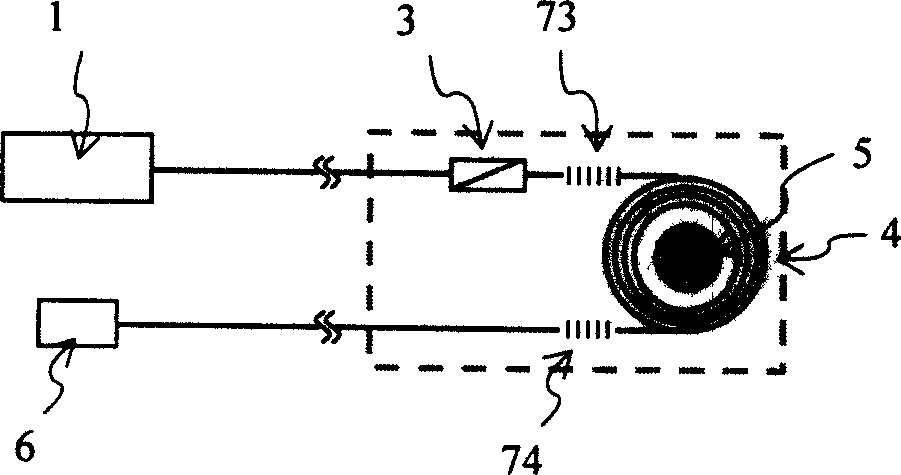

[0041] Embodiment 2: A solution for forming a fiber ring using a fiber coupler, such as image 3 shown.

[0042] 1, 3, 4, 5, 6, 21, and 22 in the figure are all connected with figure 1 same. However, instead of two separate reflectors 71, 72, one fiber optic coupler 75 is used. It can function as two reflectors. The fiber cavity is composed of a 2×2 fiber coupler 75 and a fiber ring 4: the output terminal of the polarizer 3 is connected to the first port a of the 2×2 fiber coupler 75, and the fiber coupler 75 is connected to the first port a. The second port b and the fourth port d are connected to both ends of the optical fiber ring 4 , and the third port c is connected to the second transmission optical fiber 22 . Assuming that the splitting ratio of the coupler is K%: (1-K)%, then, after the light is input from the first port a of the coupler, (1-K)% of the power is output from the third port c, and the remaining K % power is output from the fourth port d. This part o...

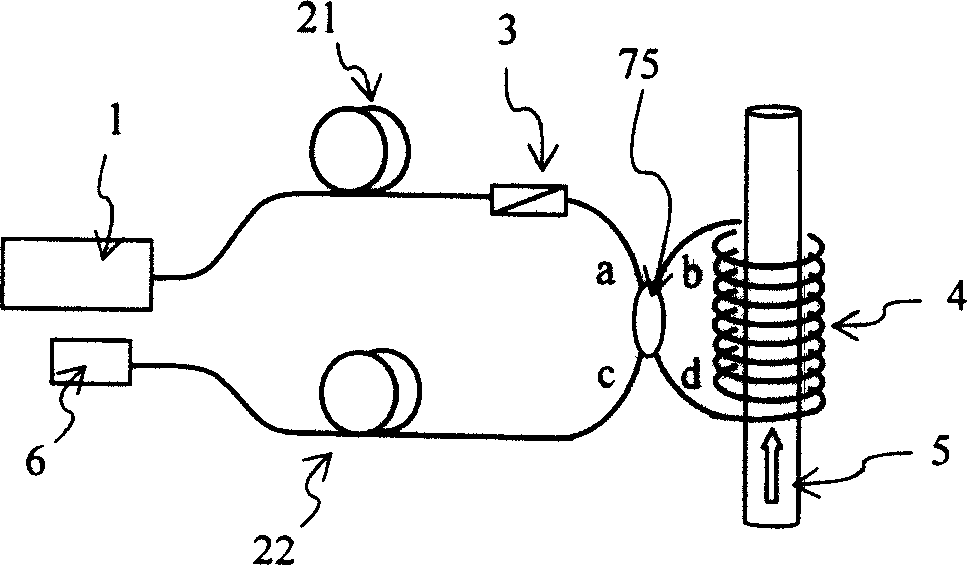

Embodiment 3

[0043] Embodiment 3: A scheme utilizing a fiber coupler and a Faraday rotating mirror, such as Figure 4 shown. Among the figure, each element such as 1, 21, 22, 3, 5, 6, 75 is all related to image 3 same. Described optical fiber cavity is formed by the first multi-turn optical fiber ring 41 and the second multi-turn optical fiber ring 42 two sections connected by the described fiber coupler 75: the first multi-turn optical fiber ring 41 and the second multi-turn optical fiber ring 42 One end is respectively connected to the second port b and the fourth port d of the fiber coupler 75, and the other ends of the first multi-turn optical fiber ring 41 and the second multi-turn optical fiber ring 42 are respectively connected to the first Faraday rotating mirror 81 and a second Faraday rotating mirror 82, the second transmission fiber 22 is directly connected to the third port c of the fiber coupler 75.

[0044] The incident light enters the sensor head through a circulator 9;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com