Anaerobe and pressure waste water treatment method and device

An anaerobic biology and wastewater pressure technology, applied in anaerobic digestion treatment, waste fuel, etc., can solve the problems of suspended solid loss, reduce the contact area between sludge particles and wastewater, reduce the purification rate of wastewater, and achieve an increase in biochemical reaction rate , excellent airtight performance, strong rigidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

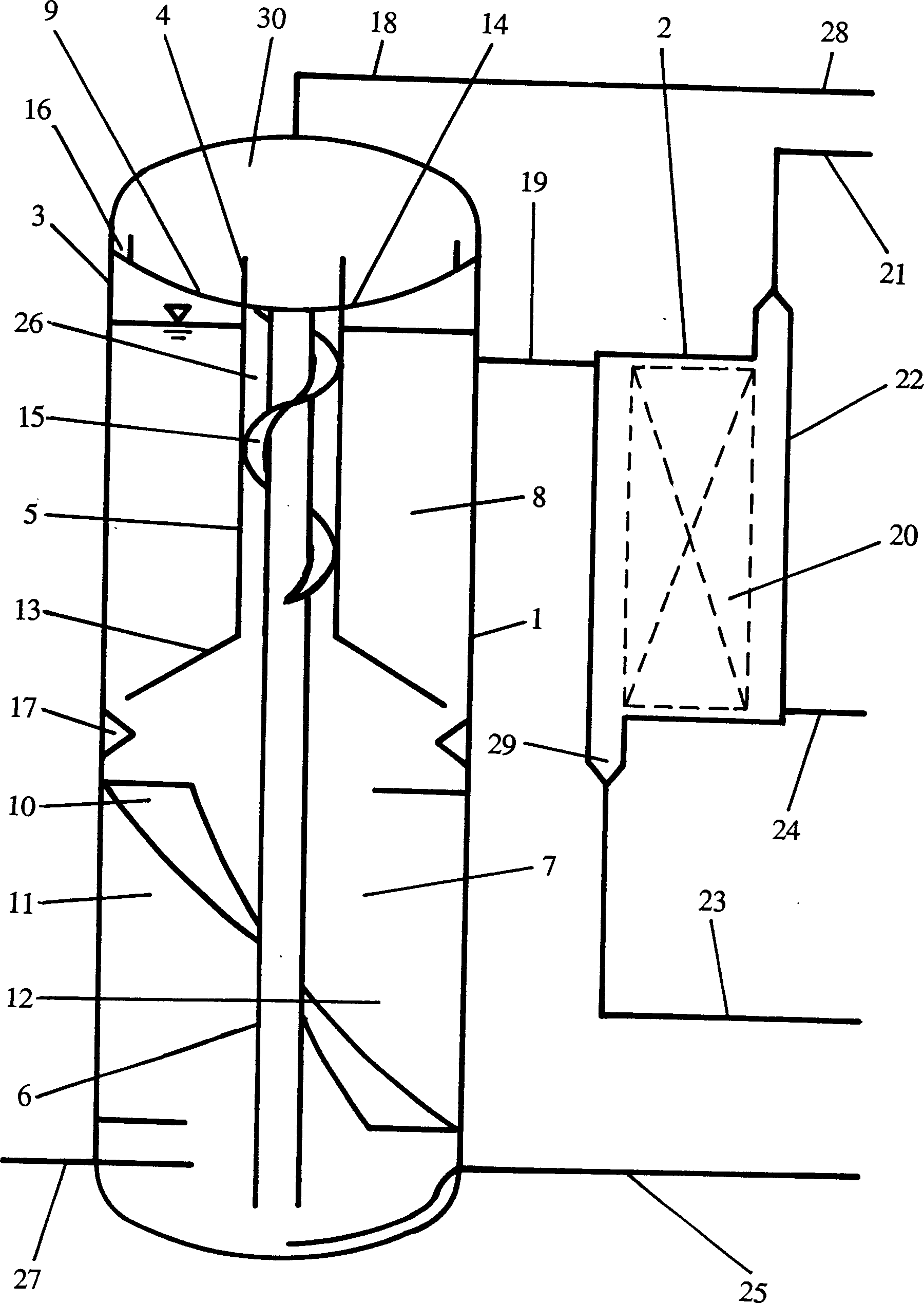

[0011] In Fig. 1, the pressure anaerobic bioreactor device [1] and the grid filter fine filter water outlet device [2] are two independent devices, which are connected by the outlet pipe [19], forming a waste water pressure anaerobic biological treatment The main body of the reactor assembly. The reactor shell [3] is a closed tower reactor with a large height-to-diameter ratio. The intermediate air seal [17] in the device separates the reactor device into a bottom reaction zone [7] and an upper reaction zone [8] Two units. In the reactor device, the double helix guide plate [10] is turned up along the inner wall of the shell, and forms two spiral guide chambers, the first guide chamber [11] and the second guide chamber [12]. With the air collecting hood [13] above, the water enters from the bottom of the reactor device with a pump, and under the distribution of the water distributor [27], the water flows in the spiral flow guide chamber in the way of turbulent flow and advect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com