Hydrogenation and quality improvement method for reducing sulfur and olefin content of inferior gasoline

A technology for olefin content and low-quality gasoline, which is applied in the fields of hydroprocessing, petroleum industry, and hydrocarbon oil treatment. It can solve the problems of poor catalyst activity stability, limited olefin content reduction, and octane loss, so as to avoid octane Value loss, reduced hydrogen consumption, and reduced olefin content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

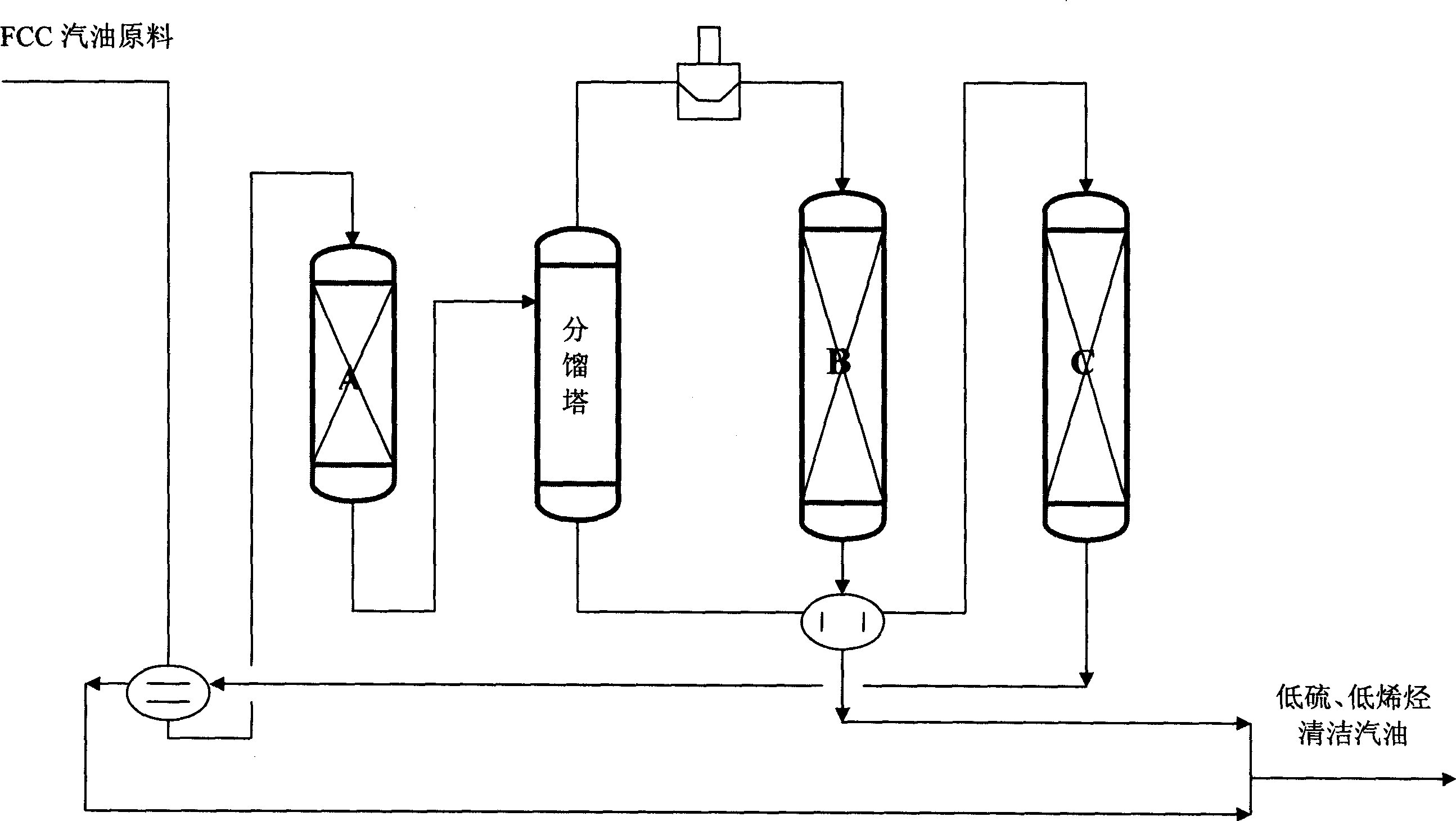

[0030] This example shows the effect of desulfurization and olefin reduction of inferior FCC gasoline with high sulfur content and high olefin content.

[0031] (1) Selective hydrogenation of feedstock oil

[0032] Reactor A loaded with MoO 3 (9.0wt%)-NiO(4.5wt%)-WO 3 (19.0wt%) / Al 2 o 3 Selective hydrogenation catalysts;

[0033] The reaction pressure is 2.8MPa, the reaction temperature is 180°C, and the volume space velocity is 6.0h -1 , The volume ratio of hydrogen to oil is 600:1.

[0034] Table 1 lists the properties of the full-cut FCC gasoline feedstock and selective hydrogenation products

[0035] project

[0036] (2), raw oil pre-fractionation

[0037] Table 2 lists the properties of light fraction and heavy fraction of FCC gasoline after selective hydrogenation by fractional distillation with 90°C as the cut point.

[0038] project

[0039] (3), light fraction upgrading

[0040] Reactor B is filled with a La 2 o 3 -ZnO / HZSM-5 aromati...

Embodiment 2

[0052] This example shows the effects of desulfurization and olefin reduction of a medium-sulfur, low-quality FCC gasoline with olefin content.

[0053] (1) Selective hydrogenation of feedstock oil

[0054] Reactor A is filled with 0.25wt% Pd / Al 2 o 3 Selective hydrogenation catalysts;

[0055] The reaction pressure is 3.2MPa, the reaction temperature is 130°C, and the volume space velocity is 8.0h -1 , The volume ratio of hydrogen to oil is 600:1.

[0056] Table 6 lists the properties of the full-cut FCC gasoline feedstock and selective hydrogenation products

[0057] project

Full Distillate FCC Gasoline

Selective Hydrogenation Products

Diene value, gI / 100g

Density, g / ml

Sulfur content, μg / g

Mercaptan content, μg / g

Olefin content, v%

Aromatic content, v%

Research octane number, RON

1.45

0.7210

662

30.5

40.5

19.5

93.2

0.03

0.7211

608

12.9

39.2

19.4

93.0

[0058] (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com