Semiconductor laser device and optical pick-up device employing the same

A laser device and semiconductor technology, applied in beam guiding devices, optical recording/reproducing, optical recording heads, etc., can solve the problems of time-consuming and labor-intensive, complex optical pickup structure, etc., and achieve the effect of reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

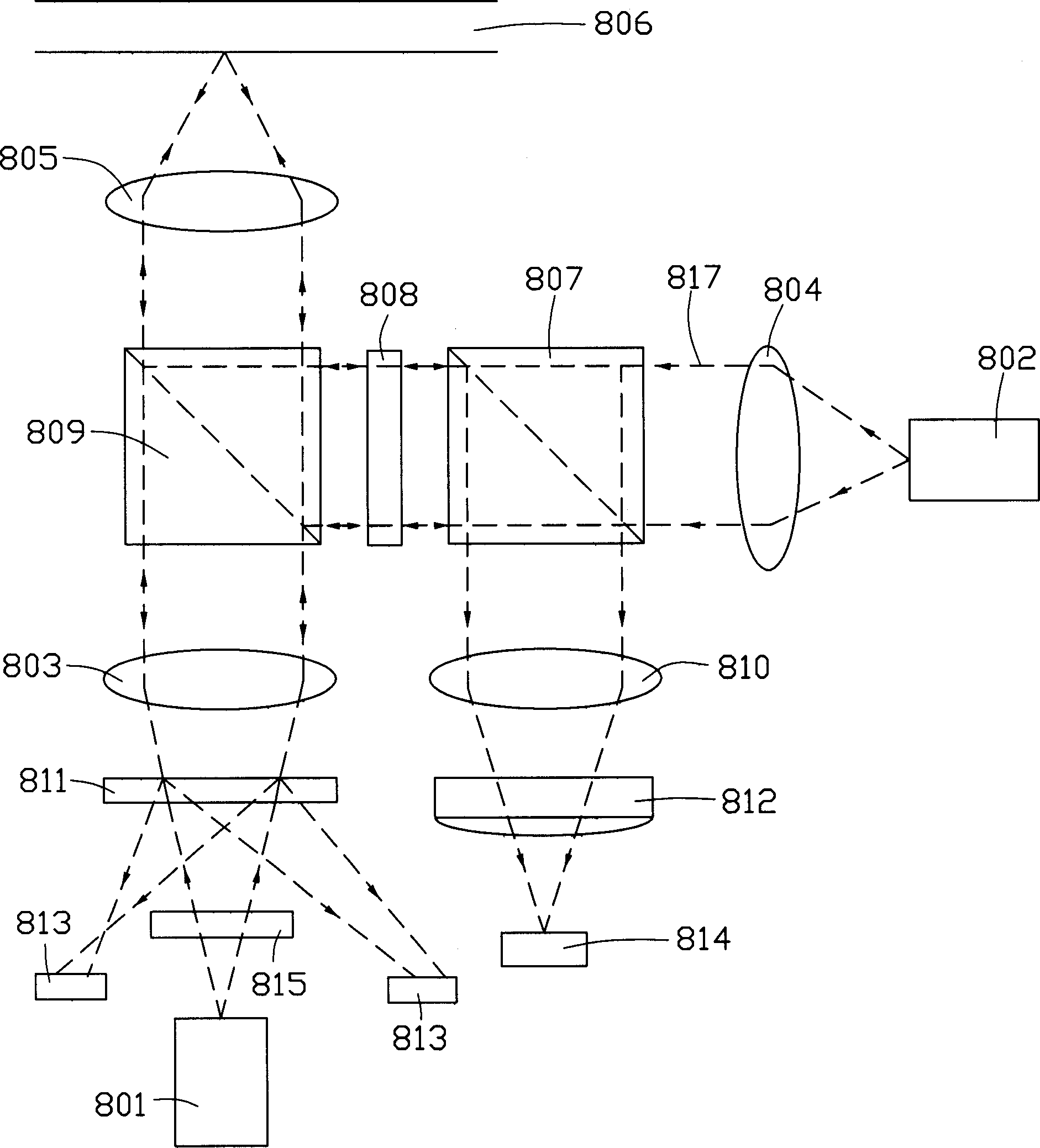

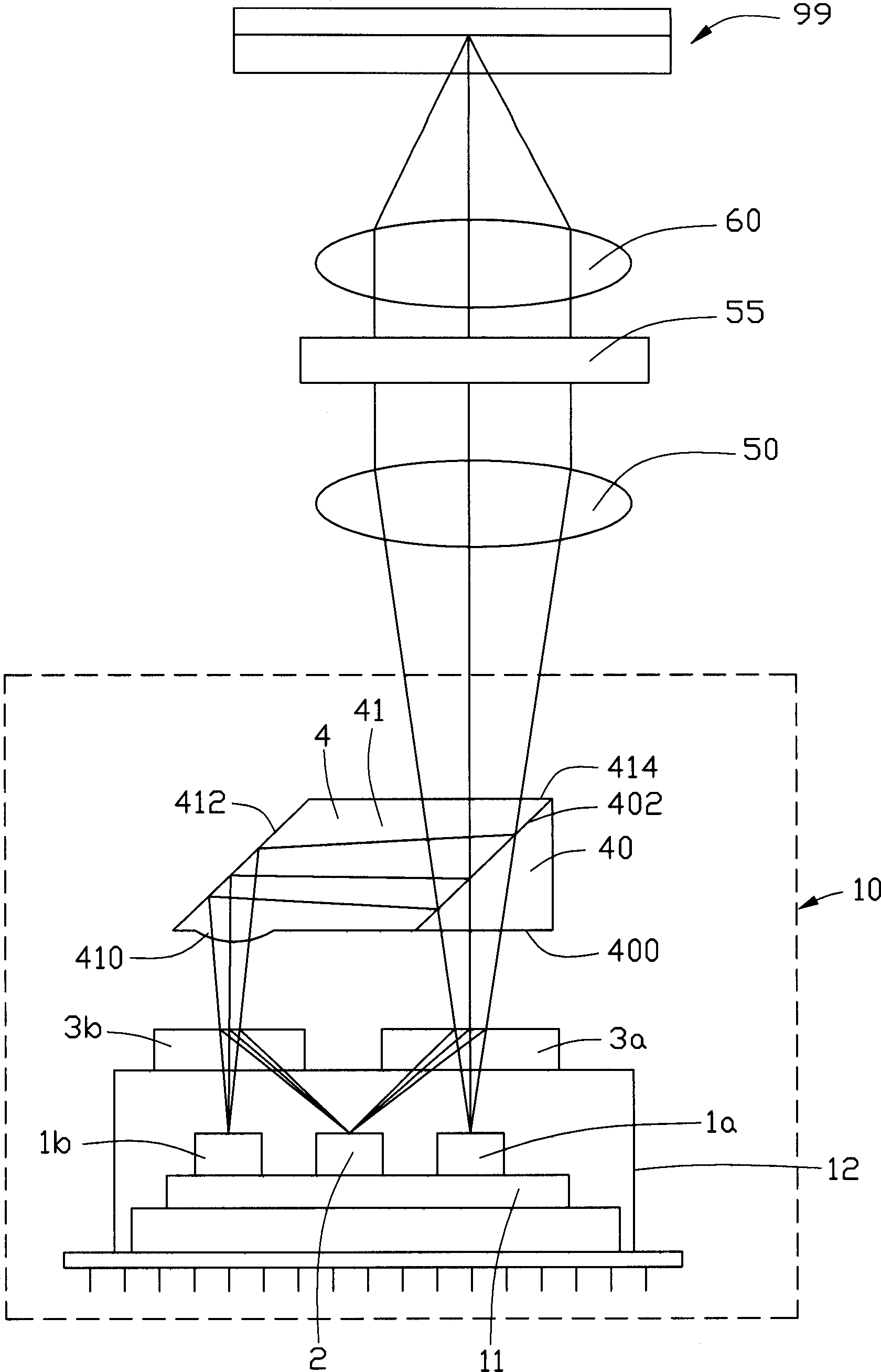

[0014] see figure 2 , an optical pick-up device 99 compatible with different disc specifications includes the semiconductor laser device 10 of the present invention, a collimator lens 50 , a wavelength selective mirror 55 and an objective lens 60 . Wherein, the semiconductor laser device 10 can emit laser beams with different wavelengths, and the collimator lens 50 and the objective lens 60 have optical parameters matching the short-wavelength laser beams. The objective lens 60 has a numerical aperture corresponding to the specification of a high-density optical disc. The wavelength selective mirror 55 is located on one side of the objective lens 60 and has different apertures for incident beams of different wavelengths.

[0015] The semiconductor laser device 10 includes a first laser source 1a, a second laser source 1b, a photodetection element 2, a first holographic element 3a, a second holographic element 3b, a composite prism 4, and a packaging case 12 . Wherein, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com