Composite article comprising a ceramic coating

A technology of ceramic coating and ceramic coating, which is applied in the direction of coating, layered products, electrolytic coating, etc., and can solve problems such as unclearness and affecting the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the following description, for purposes of explanation, numerous details are set forth in order to provide a thorough understanding of the invention. However, it is apparent that the present invention can be practiced by those skilled in the art without these detailed descriptions. In other instances, well-known structures and mechanisms are described in diagrammatic form in order not to unnecessarily obscure the invention.

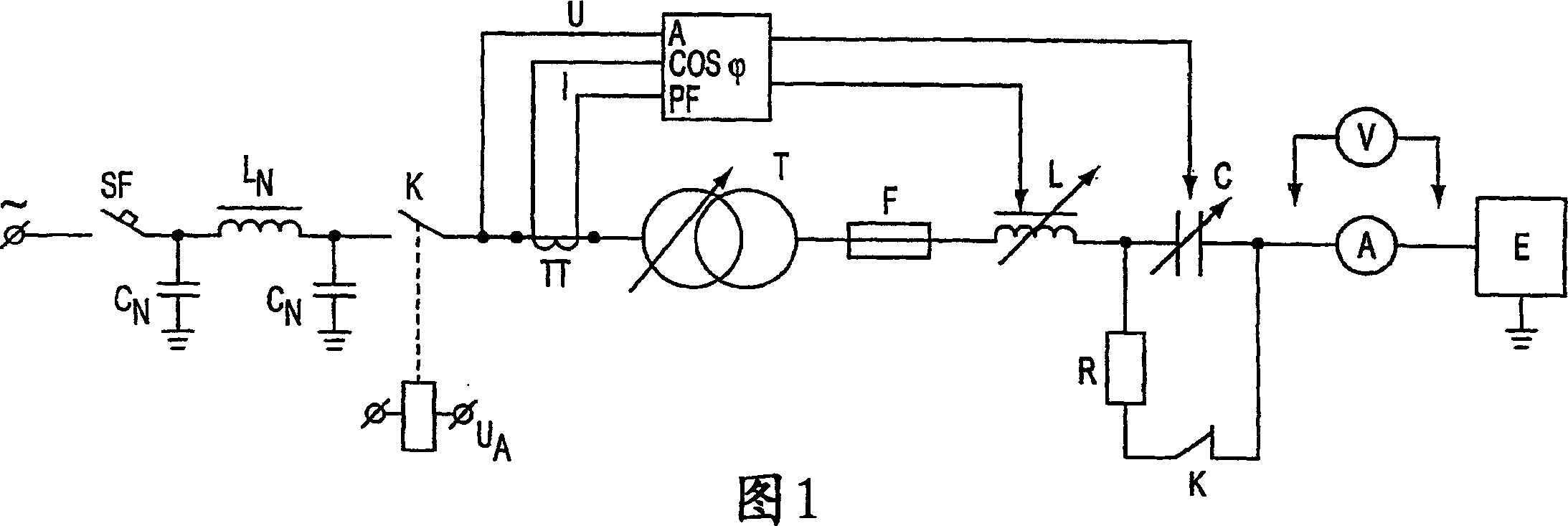

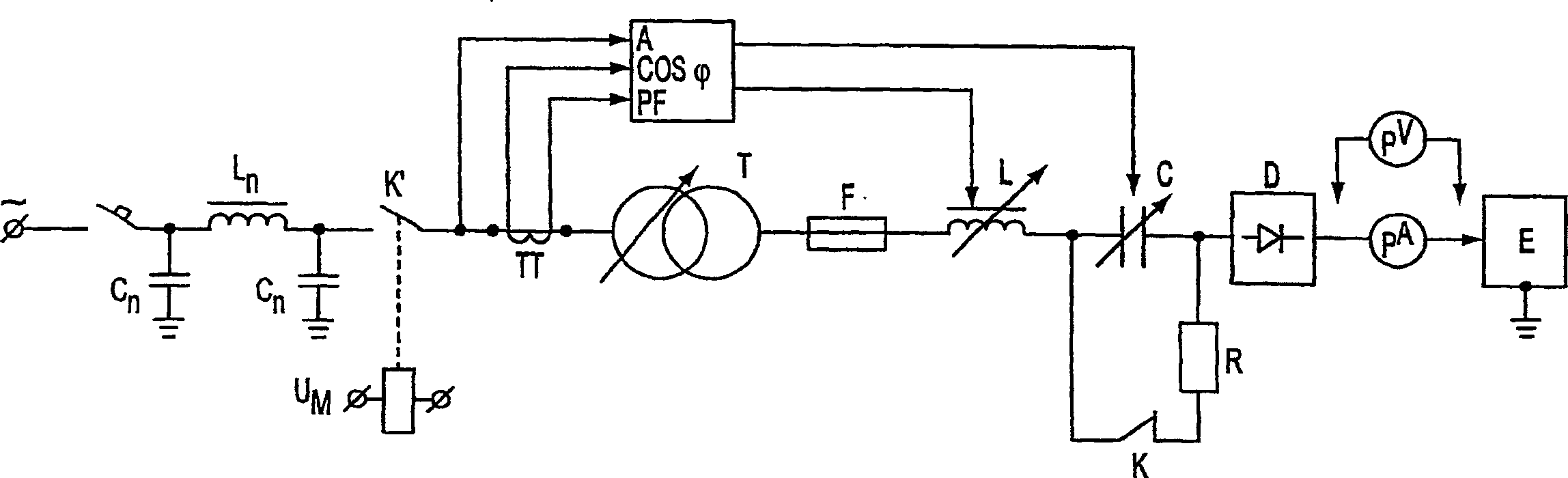

[0037] The present invention provides methods for forming ceramics on articles such as, but not limited to, valve components formed from metals, such as a metal, metals or alloys, in an alkaline electrolyte at a temperature of about 15-40°C coating. The method involves immersing the article as an electrode in an electrolytic cell containing an aqueous solution of an alkali metal hydroxide and a metal silicate, such as an alkali metal silicate, including but not limited to sodium or potassium silicate . A second electrode may be provided, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com