Fume desulfuring and denitrifying dedust apparatus and method

A technology of desulfurization, denitrification, and dust removal equipment, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve problems such as limiting the development and application of flue gas oil recovery, corroding surface pipelines and downhole oil pipes, and failing to meet oilfield production. Achieve the effect of simple implementation, low production cost and reliable technical guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

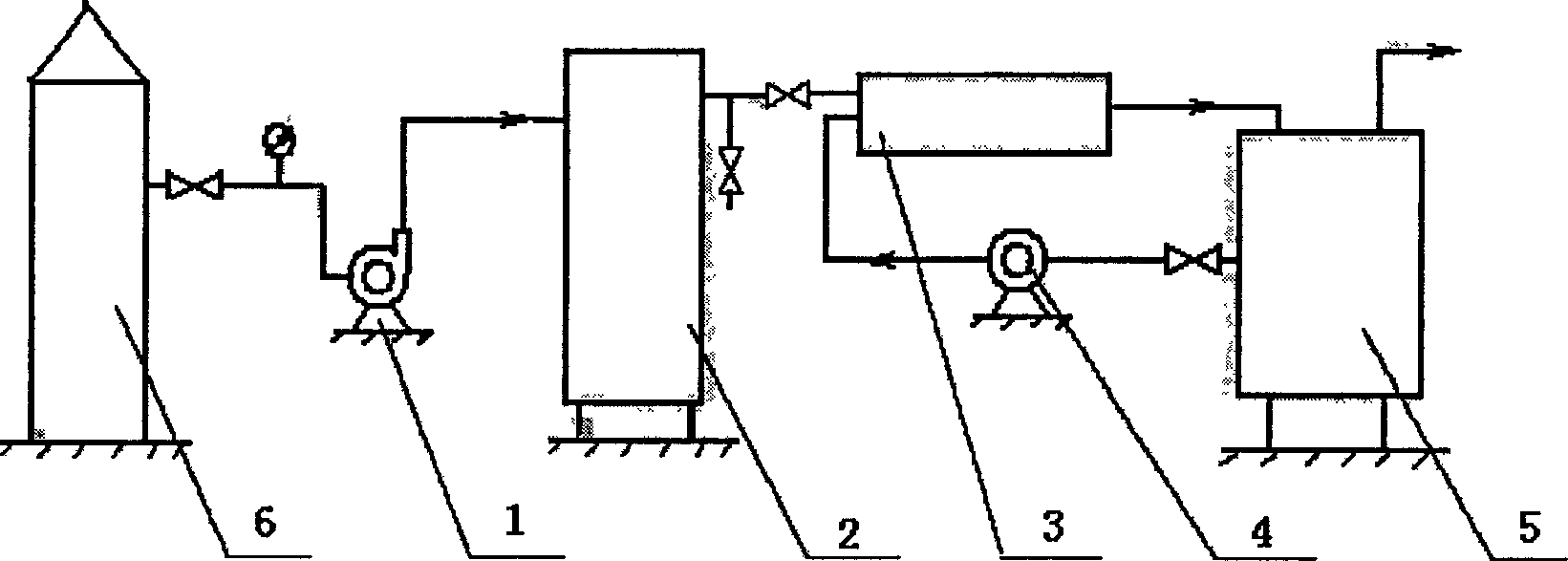

[0007] The present invention is provided by the following embodiments, which will be described below in conjunction with the accompanying drawings.

[0008] As shown in the figure, the device that the present invention adopts is made up of blower 1, air cooler 2, gas-liquid mixer 3, circulation pump 4 and circulation tank 5, and its structure, assembly relation are as follows: blower 1 side passes pipeline and steam The flue gas output pipe of the boiler 6 is connected, and the other side is connected with the air cooler 2 through the pipe; the air cooler 2 and the circulating pump 4 are respectively connected with the gas-liquid mixer 3 through the pipe; The connecting pipeline between the liquid mixer 3 is provided with a valve, the output end of the gas-liquid mixer 3 is connected to the circulation tank 5 through a pipeline, and the other end of the circulation pump 4 is connected to the circulation tank 5 through a pipeline with a valve on it . Among them, blower 1 adopt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com