Common-rail fuel injection system fuel supply pump

A technology of fuel injection system and fuel supply pump, which is applied in the direction of charging system, fuel injection pump, fuel injection device, etc., can solve the problems of affecting the sliding property of the plunger, large assembly stress, poor assembly process, etc., to improve performance and Reliability, improve work reliability, improve the effect of assembly and disassembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The structural features and assembly conditions of the fuel supply pump of the common rail fuel injection system designed according to the present invention will be described in detail below in conjunction with the accompanying drawings.

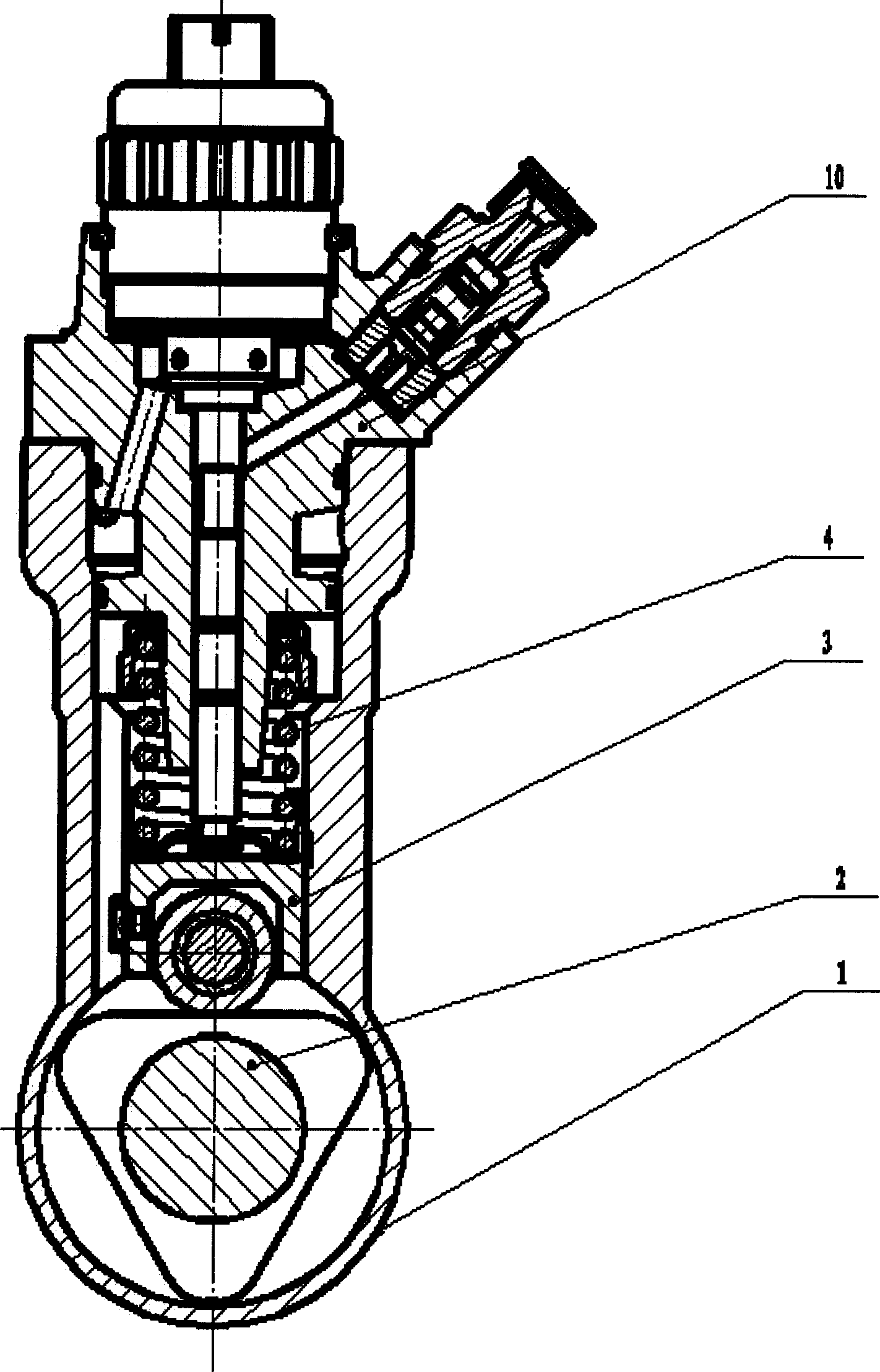

[0012] figure 1 Shown is a fuel supply pump for a common rail fuel injection system of a low-emission compression ignition engine (diesel engine) designed according to the present invention. The camshaft (2) installed in the pump body (1) among the figure is driven to rotate by the engine. Rotating camshaft drives oil pumping part (10) and oil delivery pump (not shown among the figure) work through tappet body part (3) and plunger spring (4). When the oil pumping part (10) works, it can provide high-pressure fuel oil with a pressure of 160MPa or higher to the common rail pipe.

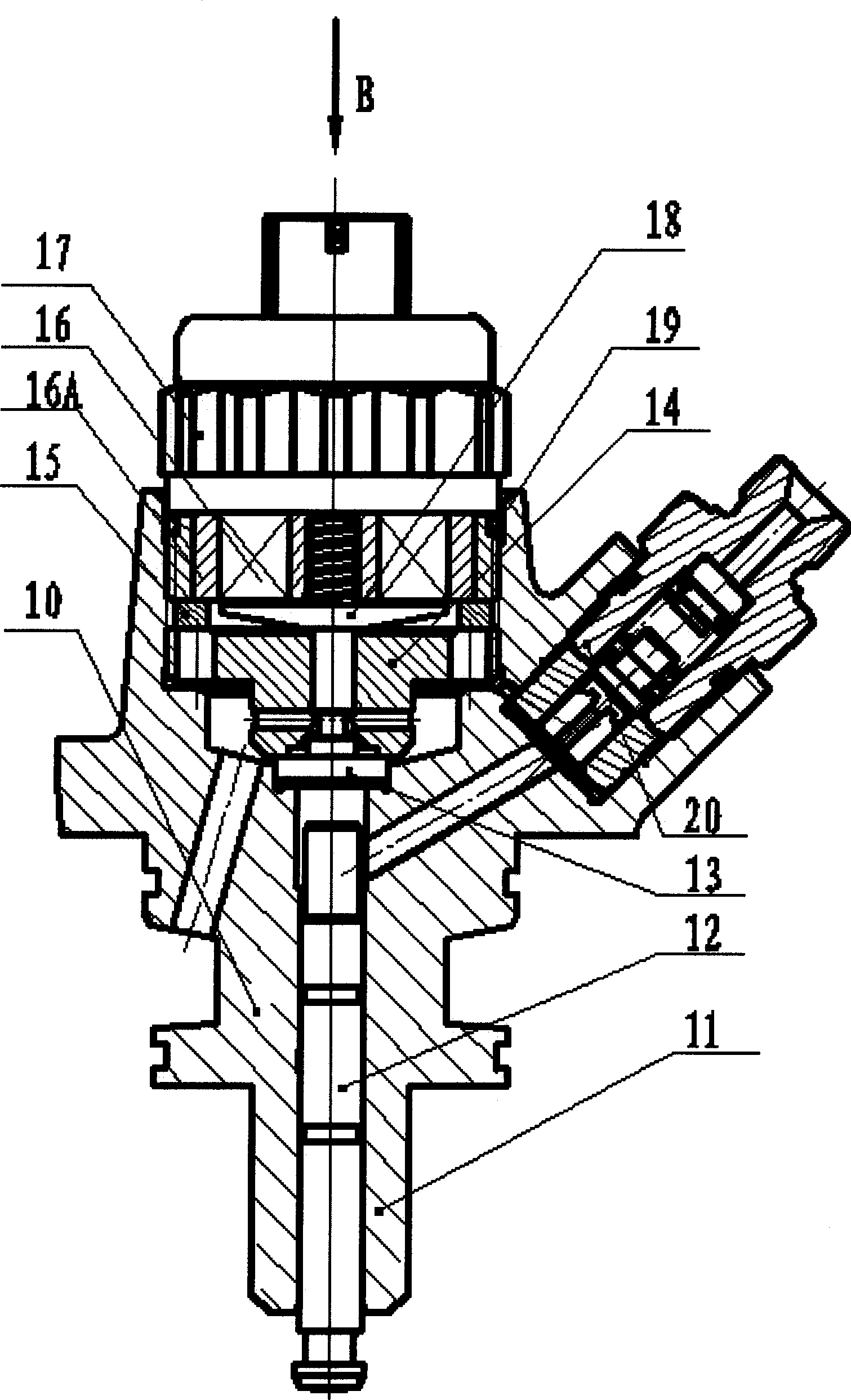

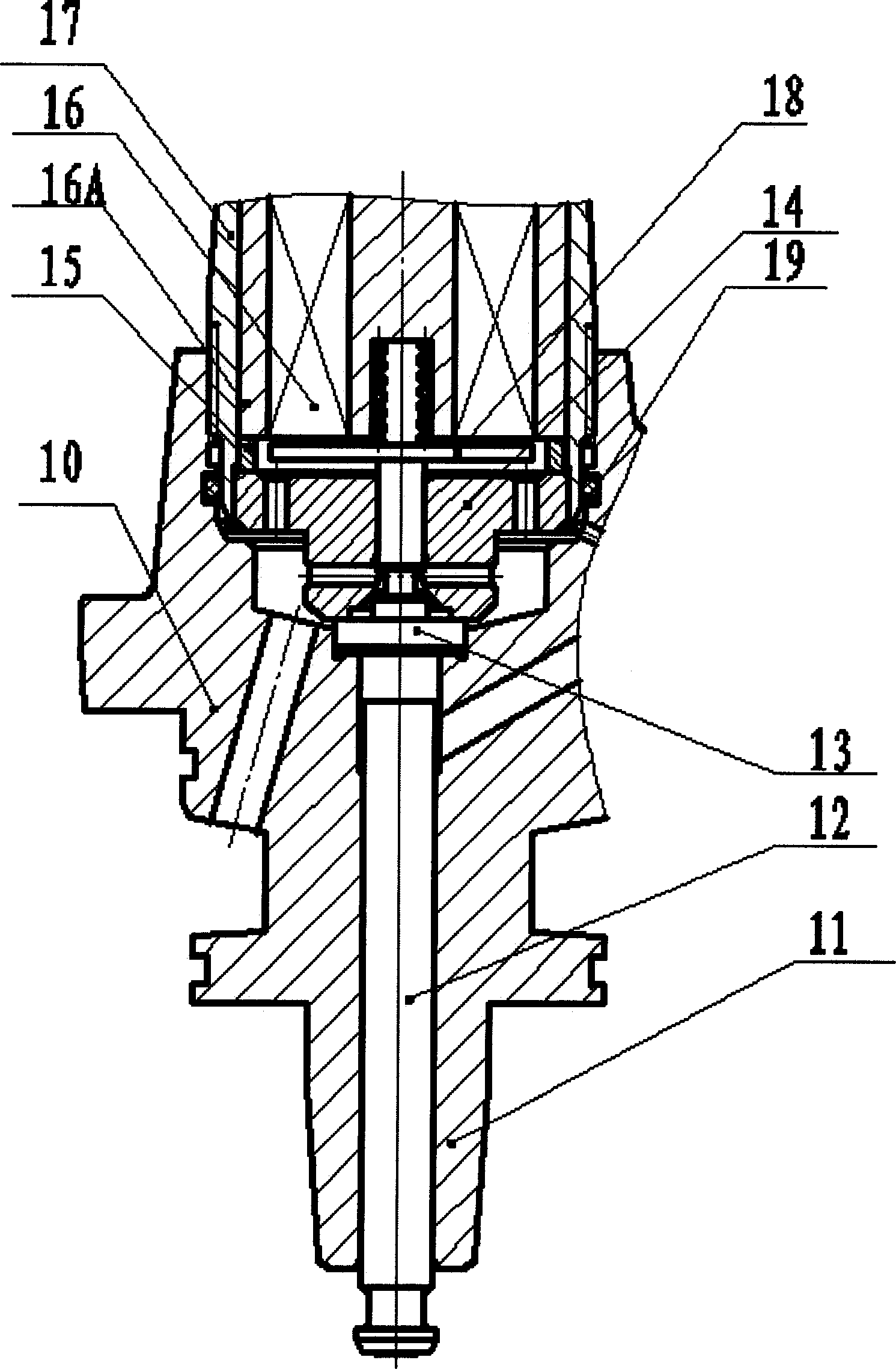

[0013] figure 2 Shown is the structure of the oil pumping part (10) in this embodiment. Among them, the oil pumping part (10) consists of a plunger slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com