Process for producing pipe sleeves from mineral wool and this pipe sleeves

A tube sleeve and mineral wool technology, applied in chemical instruments and methods, pipes/pipe joints/fittings, applications, etc., can solve complex and problem-prone problems, achieve mechanical properties improvement, reduce bulk density, and improve material properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

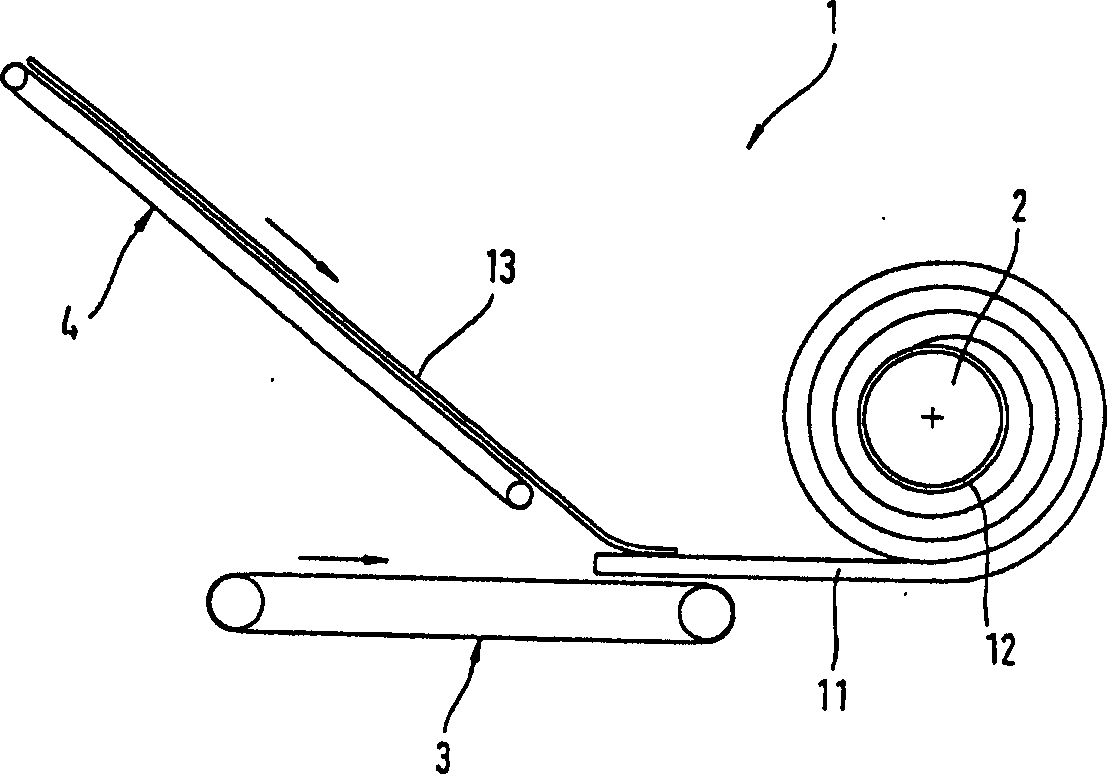

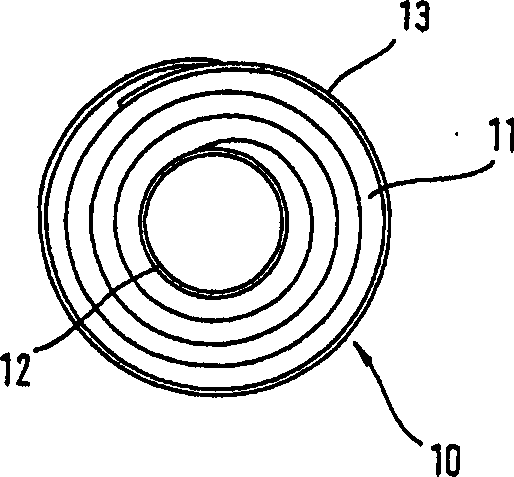

[0036] figure 1 A side view of a winding machine 1 is shown in a highly schematic manner, on which a sleeve 10 according to a first embodiment is produced (cf. figure 2 ). The winding machine 1 has a winding mandrel 2 , onto which a nonwoven web 11 made of mineral wool is wound up in an inherently conventional manner, the nonwoven web 11 being supplied by a first supply belt 3 .

[0037] In the shown figure, the nonwoven web 11 has been substantially wound on the winding mandrel 2, and the inner reinforcement layer 12 has been placed on the winding mandrel 2 before starting the winding operation, so that during the winding operation , the reinforcing layer becomes an integral part of the sleeve 10 to be produced.

[0038] Furthermore, the winder 1 comprises a second supply belt 4, via which the outer reinforcing layer 13 can be supplied in such a way that its front end partially overlaps the end of the nonwoven web 11 so that it is also wound into rolls. As a result of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com