Through-flow vacuum seawater desalination plant and method thereof

A through-flow, vacuum technology, applied in seawater treatment, general water supply saving, heating water/sewage treatment, etc., can solve the problems of power consumption, large power consumption, energy loss, etc., to eliminate cycle power consumption and reduce steam generation Consumption and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

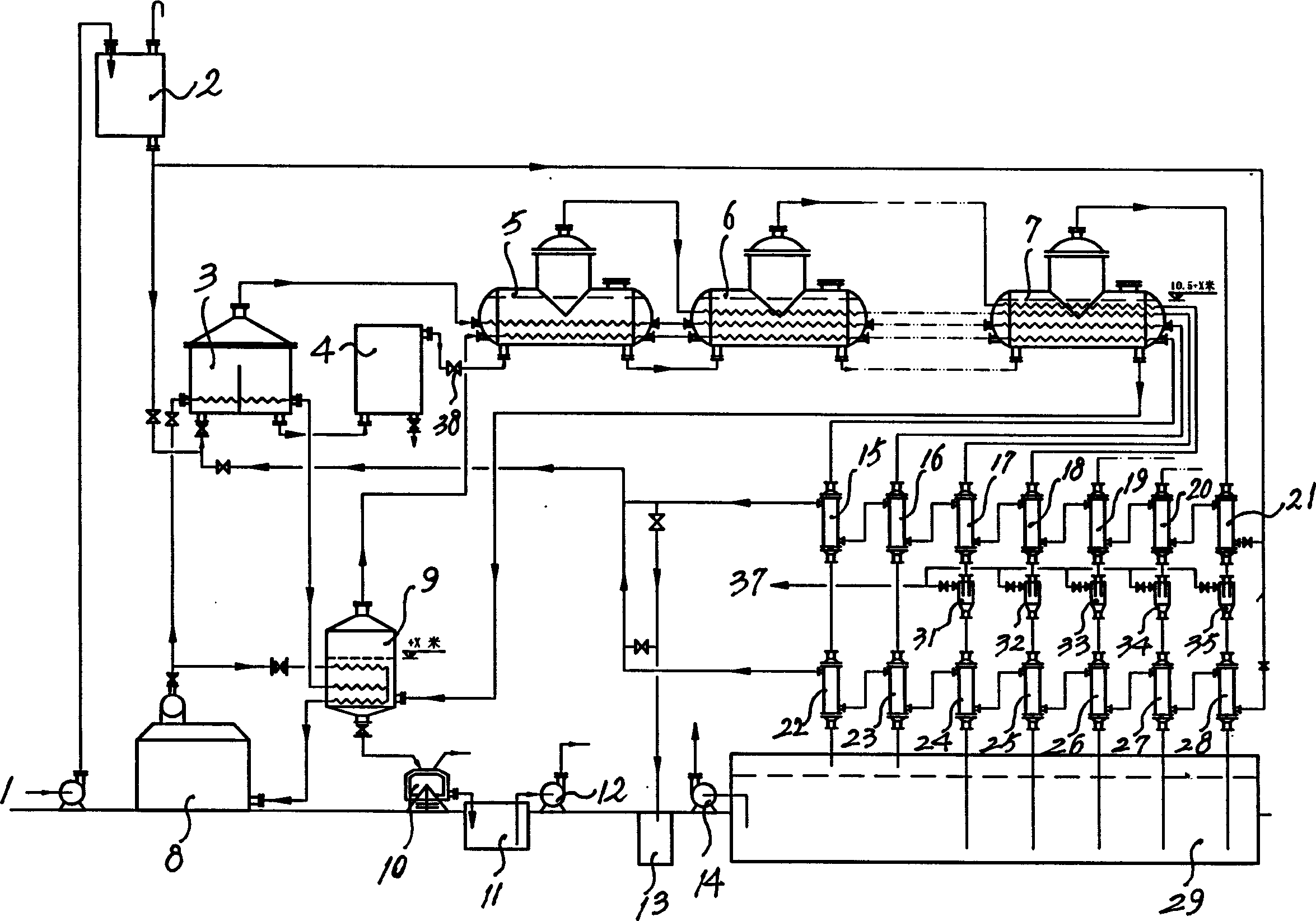

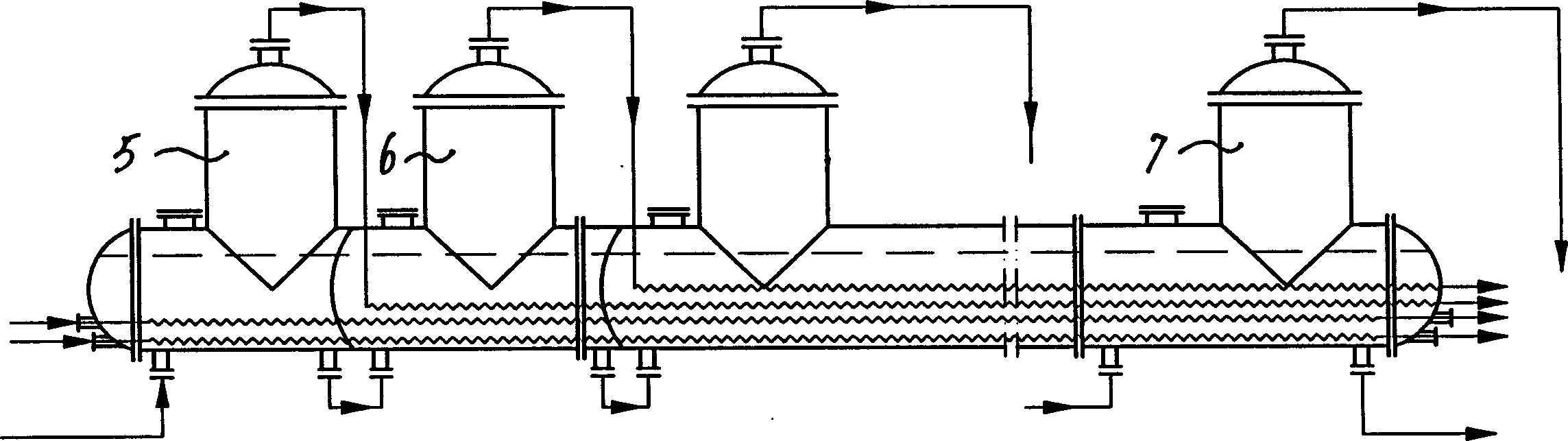

[0015] The invention discloses a low-energy-consumption through-flow automatic vacuum seawater desalination device and method, which is a joint process of desalinating seawater, producing salt and brine by using a multi-effect distillation method. So a device such as figure 1 , figure 2 As shown, the seawater pump 1 is connected to the seawater tower 2 through the pipeline, the seawater tower is connected to the degassing tank 3, and the degassing tank 3 is respectively connected to the multi-effect tanks 5, 6, 7, single decalcification softening tank 4, low-pressure boiler 8, replacement Heater 22 and condenser 15, its heat exchangers 22, 23, 24, 25, 26, 27, 28 etc. are connected in series, and heat exchanger 28 is connected to seawater tower 2 again, and its condensers 15, 16, 17, 18 , 19, 20, and 21 are also multiple in series, and the condenser is also connected to the seawater tower 2. The multi-effect tanks 5, 6, and 7 are one-effect, two-effect...N-effect, and each mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com