Coating composition, porous siliceous film, method for preparing porous siliceous film, and semiconductor device

A composite, porous silicon technology, applied in semiconductor/solid-state device manufacturing, coating, silicon oxide, etc., can solve problems such as elastic modulus limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

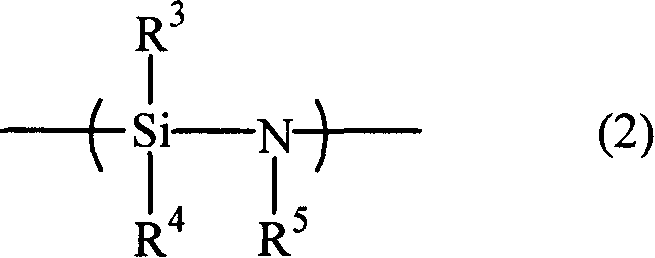

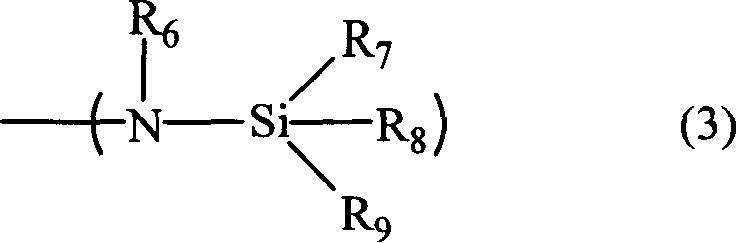

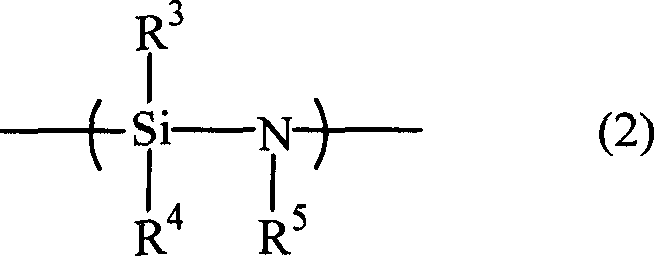

Method used

Image

Examples

Embodiment

[0078] The following examples further illustrate the invention. In the following examples, the physical properties of siliceous films were evaluated by the following methods.

[0079] (Relative dielectric constant) A Pyrex (registered trademark) glass plate (thickness 1mm, size 50mm×50mm) produced by Corning Inc. 2 SO 4 The aqueous solution is sequentially rinsed and then dried. An Al film (0.2 µm) was formed on the entire surface of the glass plate by vacuum vapor deposition. The composition solution was spin-coated on the glass plate to form a film, and then the four corners of the glass plate were rubbed with a cotton swab to remove the polyalkylsilazane film (about 3 mm×3 mm) for electrode signal acquisition. Subsequently, the film was converted into a siliceous film according to the methods in Examples or Comparative Examples. A SUS mask was placed on the silicon film thus formed, and an Al film (18 patterns with a size of 2 mm x 2 mm square and a thickness of 2 μm) w...

reference example 1

[0089] Reference Example 1 [Synthesis of polymethylsilazane (1)]

[0090] A stainless steel tank for raw material supply was installed on a stainless steel tank reactor with an internal volume of 5 L. The air in the reactor was replaced with dry nitrogen. Thereafter, 780 g of methyltrichlorosilane was put into a stainless steel tank for raw material supply and fed by nitrogen pressure and introduced into the reaction tank. Next, a raw material supply tank containing pyridine was connected to the reactor, and 4 kg of pyridine was supplied with nitrogen pressure in the same manner as described above. Adjust the pressure of the reactor to 1.0kg / cm 2 , and the temperature was adjusted so that the temperature of the mixed solution in the reactor reached -4°C. Ammonia is blown into the mixed solution while stirring, and when the pressure of the reactor reaches 2.0kg / cm 2 When, stop the supply of ammonia. The vent line was opened to reduce the pressure in the reactor, and, next,...

reference example 2

[0091] Reference Example 2 [Synthesis of polymethylsilazane (2)]

[0092] In addition to using a mixture of 720 g (about 4.8 mol) of methyltrichlorosilazane and 65 g (about 0.5 mol) of dimethyldichlorosilazane (methylchlorosilane: dimethyldichlorosilane = 95:10 (mol / mol)) was used as a raw material instead of 780 g of methyltrichlorosilazane, and polymethylsilazane (about 370 g) was synthesized in the same manner as in Reference Example 1. By GPC (developing solution: CHCl 3 ) of the polymethylsilazane thus obtained was measured and found to have a molecular weight of 1400 in terms of polystyrene. In the IR (infrared absorption) spectrum of this polymethylsilazane, in the wave number (cm -1 ) at 3350 and about 1200 attributable to N-H; at 2900 and 1250 attributable to Si-C; and at 1020-820 attributable to Si-N-Si absorb.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com