Three-dimensional stephanoporate organization engineering bracket material, fibre cementing method preparing same and applications thereof

A tissue engineering scaffold, a three-dimensional porous technology, is used in medical science, prostheses, bone implants, etc. to achieve the effects of stable scaffold system structure, simple preparation process and uniform pore structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

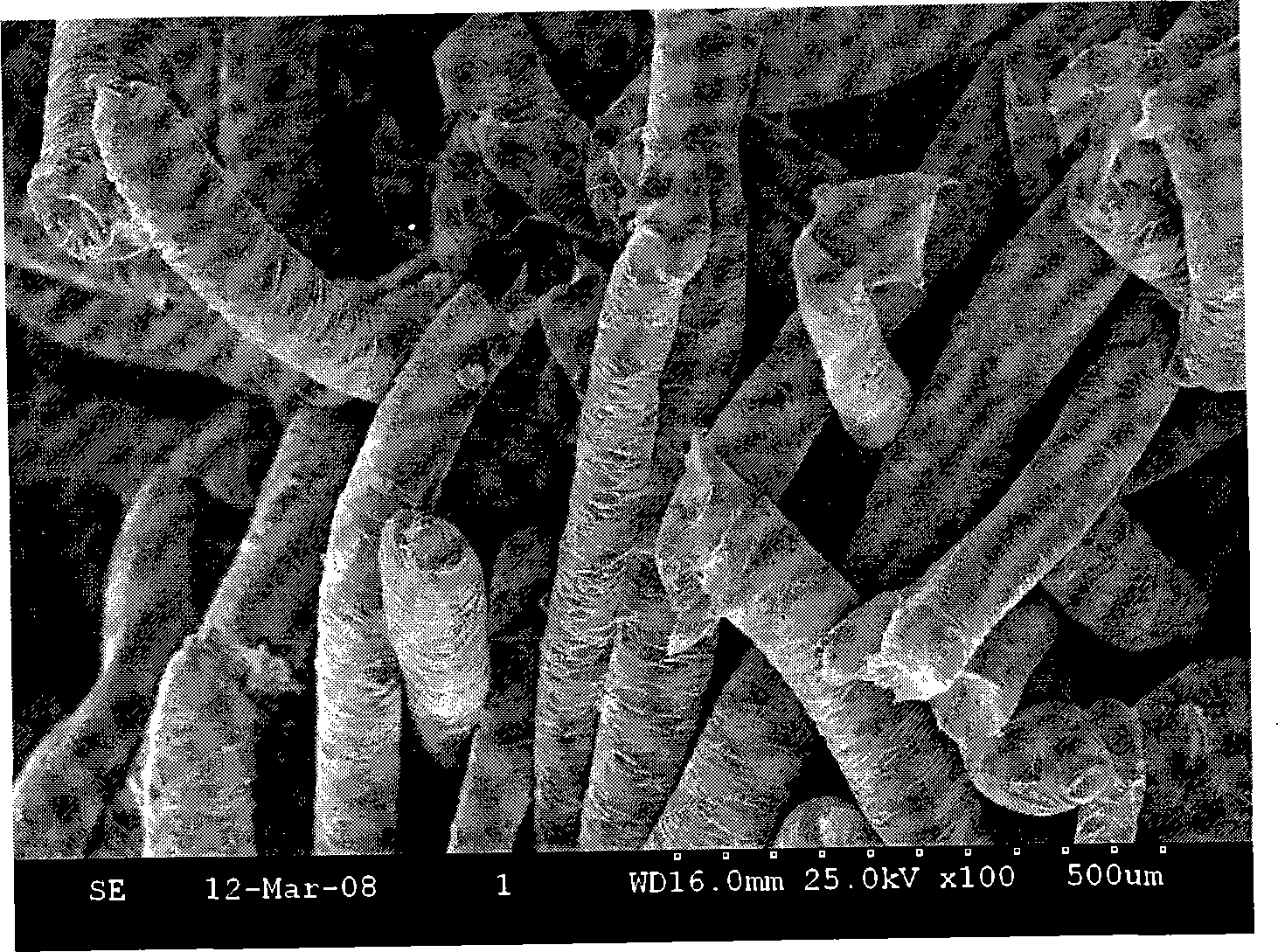

[0025] The high polymer PBS with a molecular weight of 40,000 and a melting point of 115°C, and the high polymer PCL with a molecular weight of 80,000 and a melting point of 63°C were melt-spun at 130°C to obtain fibers with an average diameter of 300 μm, which were cut into After the equal length is 8.0mm, fill it into a mold with a specific shape. The filling quality is calculated based on the porosity of 85%. After demoulding, the tissue engineering carrier material with specific shape and good performance can be obtained. The material has a pore size of 160-400 μm measured by a scanning electron microscope, a porosity of 80% measured by a liquid displacement method, and a degree of pore penetration of more than 90%. The in vitro degradation cycle is appropriate and the mechanical properties are excellent. The material can be used as a bone tissue engineering carrier material for repairing and reconstructing bone damage.

Embodiment 2

[0027] The high polymer PBS with a molecular weight of 80,000 and a melting point of 115°C, and the high polymer PCL with a molecular weight of 100,000 and a melting point of 63°C were melt-spun at 140°C to obtain fibers with an average diameter of 100 μm, which were cut into After the equal length is 10.0mm, fill it into a mold with a specific shape. The filling quality is calculated based on the porosity of 85%. After demoulding, the tissue engineering carrier material with specific shape and good performance can be obtained. The material has a pore diameter of 70-200 μm measured by a scanning electron microscope, a porosity of 85% measured by a liquid displacement method, and a degree of pore penetration of more than 90%. The in vitro degradation cycle is appropriate and the mechanical properties are excellent. The material can be used as a bone tissue engineering carrier material for repairing and reconstructing bone damage.

Embodiment 3

[0029] The high polymer PBS with a molecular weight of 100,000 and a melting point of 118°C, and the high polymer PCL with a molecular weight of 200,000 and a melting point of 64°C were melt-spun at 150°C to obtain fibers with an average diameter of 140 μm, which were cut into After the equal length is 8.0mm, fill it into a mold with a specific shape. The filling quality is calculated based on the porosity of 85%. The temperature of the vacuum oven is set at 80°C. After demoulding, the tissue engineering carrier material with specific shape and good performance can be obtained. The material has a pore size of 100-200 μm measured by a scanning electron microscope, a porosity of 81% measured by a liquid displacement method, and a degree of pore penetration of more than 90%. The in vitro degradation cycle is appropriate and the mechanical properties are excellent. The material can be used as a bone tissue engineering carrier material for repairing and reconstructing bone damage. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com