Three-dimensional porous tissue engineering bracket material, preparation and application thereof

A tissue engineering scaffold, three-dimensional porous technology, applied in medical science, prosthesis, bone implants, etc., to achieve the effects of stable structure, uniform pore structure and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

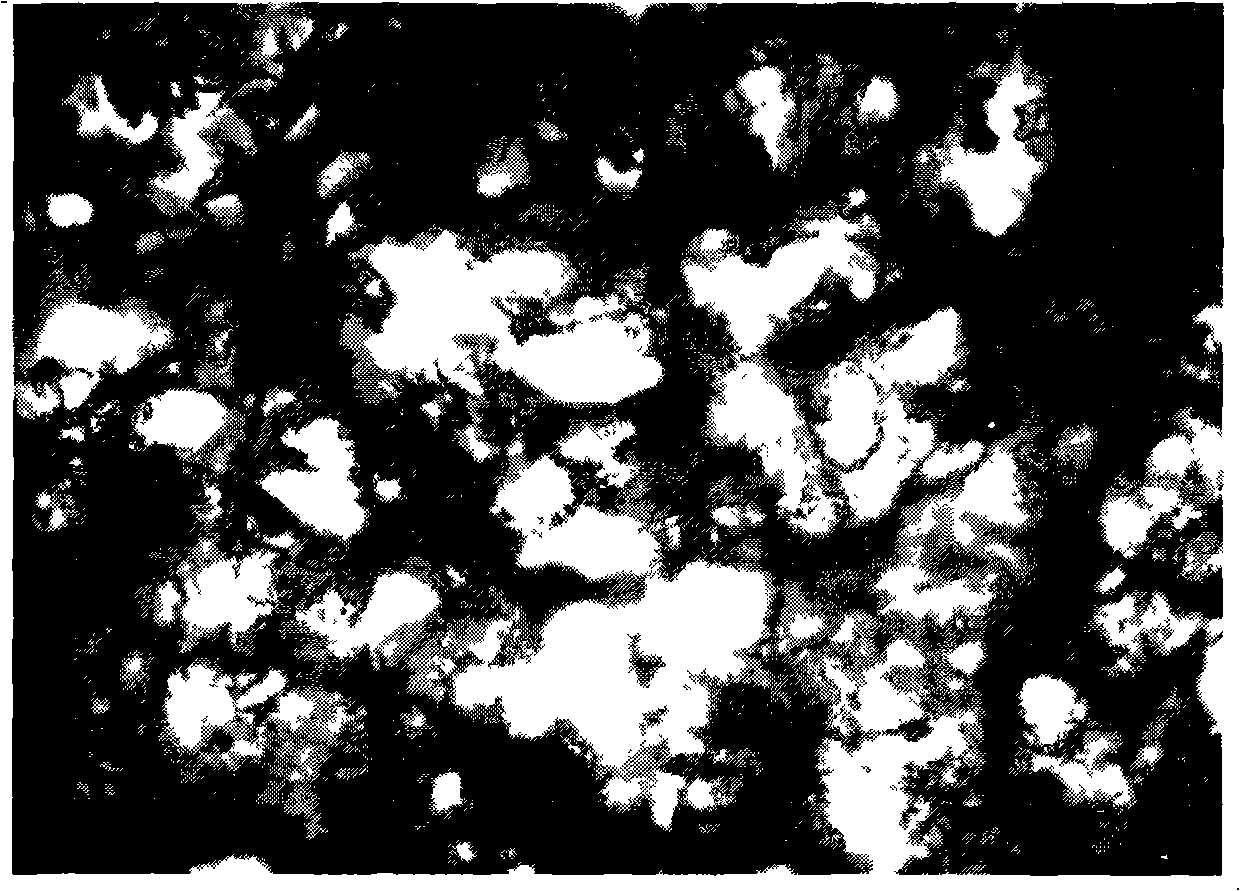

[0027] The high polymer PBS with a molecular weight of 40,000 and a melting point of 115°C, and the high polymer PCL with a molecular weight of 80,000 and a melting point of 63°C were completely dissolved in chloroform at 25°C, and stirred evenly to make a mass percentage concentration For a 20% blend solution, uniformly place sodium chloride with a diameter of 50-200 μm in the mold, pour the PBS / PCL blend solution until it just submerges the porogen in the mold, and place the bracket material in a fume hood for 24 hours, until the solvent was completely volatilized, immersed in deionized water for 4 days to leach the sodium chloride particles, during which the water was replaced every 6 hours, and vacuum-dried to obtain a three-dimensional porous PBS / PCL scaffold with a sponge structure. The material has a pore size of 10-200 μm measured by a scanning electron microscope, a porosity of 85% measured by a liquid displacement method, a degree of pore penetration of more than 90%,...

Embodiment 2

[0029] The high polymer PBS with a molecular weight of 80,000 and a melting point of 115°C, and the high polymer PCL with a molecular weight of 100,000 and a melting point of 63°C were completely dissolved in chloroform at 25°C, and stirred evenly to make a mass percentage concentration 10% blend solution, uniformly place sodium chloride with a diameter of 300-500 μm in the mold, pour PBS / PCL blend solution until just submerged in the porogen in the mold, place the bracket material in a fume hood for 24 hours, until the solvent was completely volatilized, immersed in deionized water for 4 days to leach the sodium chloride particles, during which the water was replaced every 6 hours, and vacuum-dried to obtain a three-dimensional porous PBS / PCL scaffold with a sponge structure. The material has a pore diameter of 10-500 μm measured by a scanning electron microscope, a porosity of 89% measured by a liquid displacement method, a degree of pore penetration of more than 90%, an appr...

Embodiment 3

[0031] The high polymer PBS with a molecular weight of 100,000 and a melting point of 118°C, and the high polymer PCL with a molecular weight of 150,000 and a melting point of 64°C were completely dissolved in chloroform at 30°C and stirred evenly to make a mass percentage concentration 6% blend solution, uniformly place sodium chloride with a diameter of 400-500 μm in the mold, pour PBS / PCL blend solution until just submerged in the porogen in the mold, place the bracket material in a fume hood for 24 hours, until the solvent was completely volatilized, immersed in deionized water for 4 days to leach the sodium chloride particles, during which the water was replaced every 6 hours, and vacuum-dried to obtain a three-dimensional porous PBS / PCL scaffold with a sponge structure. The pore diameter of the material measured by the scanning electron microscope is 10-500 μm, the porosity measured by the liquid displacement method is 83%, the degree of pore penetration reaches more than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com