Polygon mirror drive motor and laser mirror radiation device

A technology for driving motors and polygonal mirrors, applied in electromechanical devices, optics, electrical components, etc., can solve problems such as difficulty in correct measurement, adverse effects of installation errors, and reduced detection accuracy, to prevent the decline of detection accuracy and prevent laser light. Effect of Variation in Irradiation Interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Next, the best mode for carrying out the present invention will be described with reference to the drawings.

[0062] [mechanical configuration]

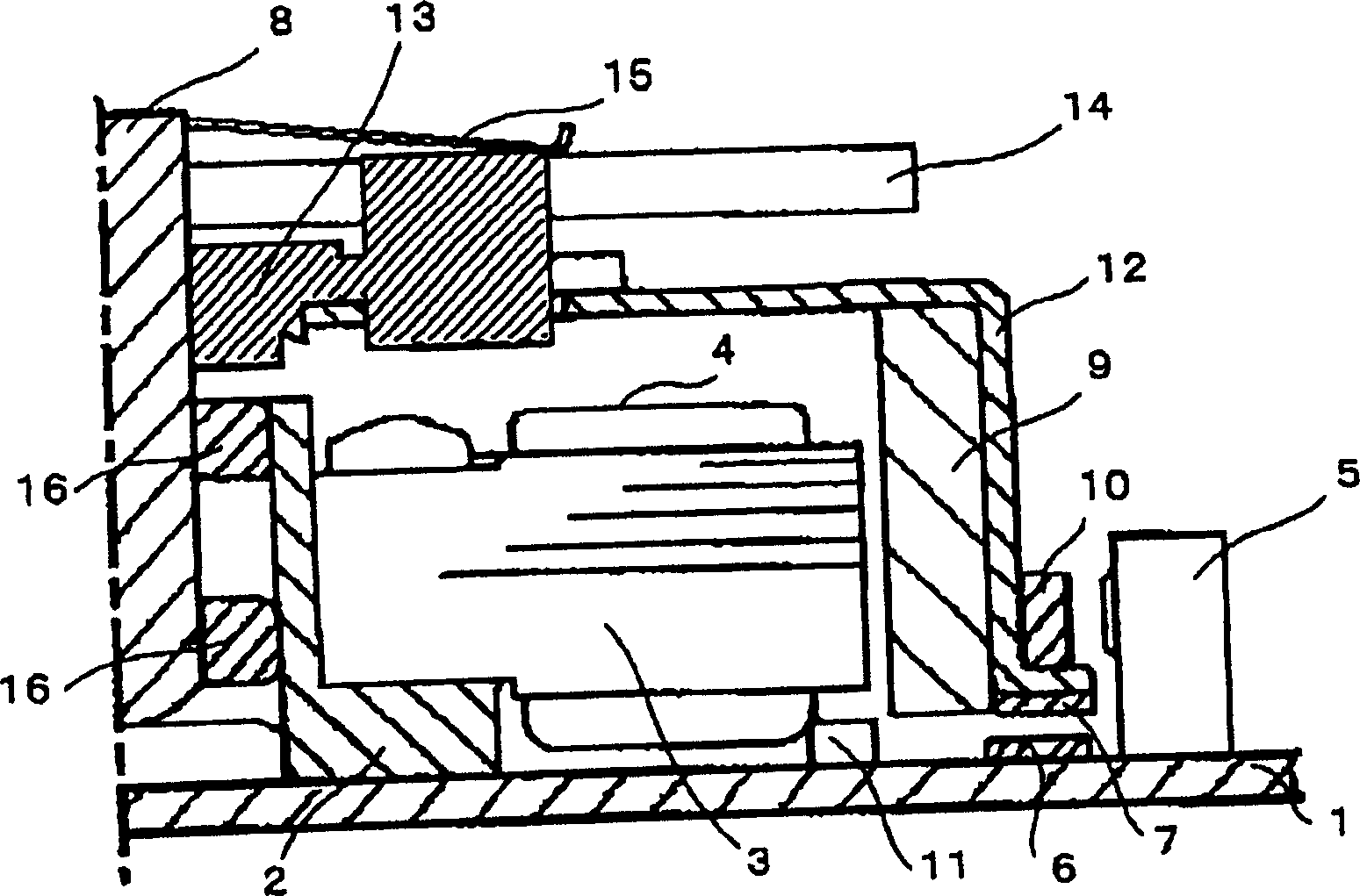

[0063] figure 1 It is a cross-sectional view of a polygon mirror driving motor according to an embodiment of the present invention. figure 1 For the sake of convenience, only the right half of the rotating shaft 8 is shown.

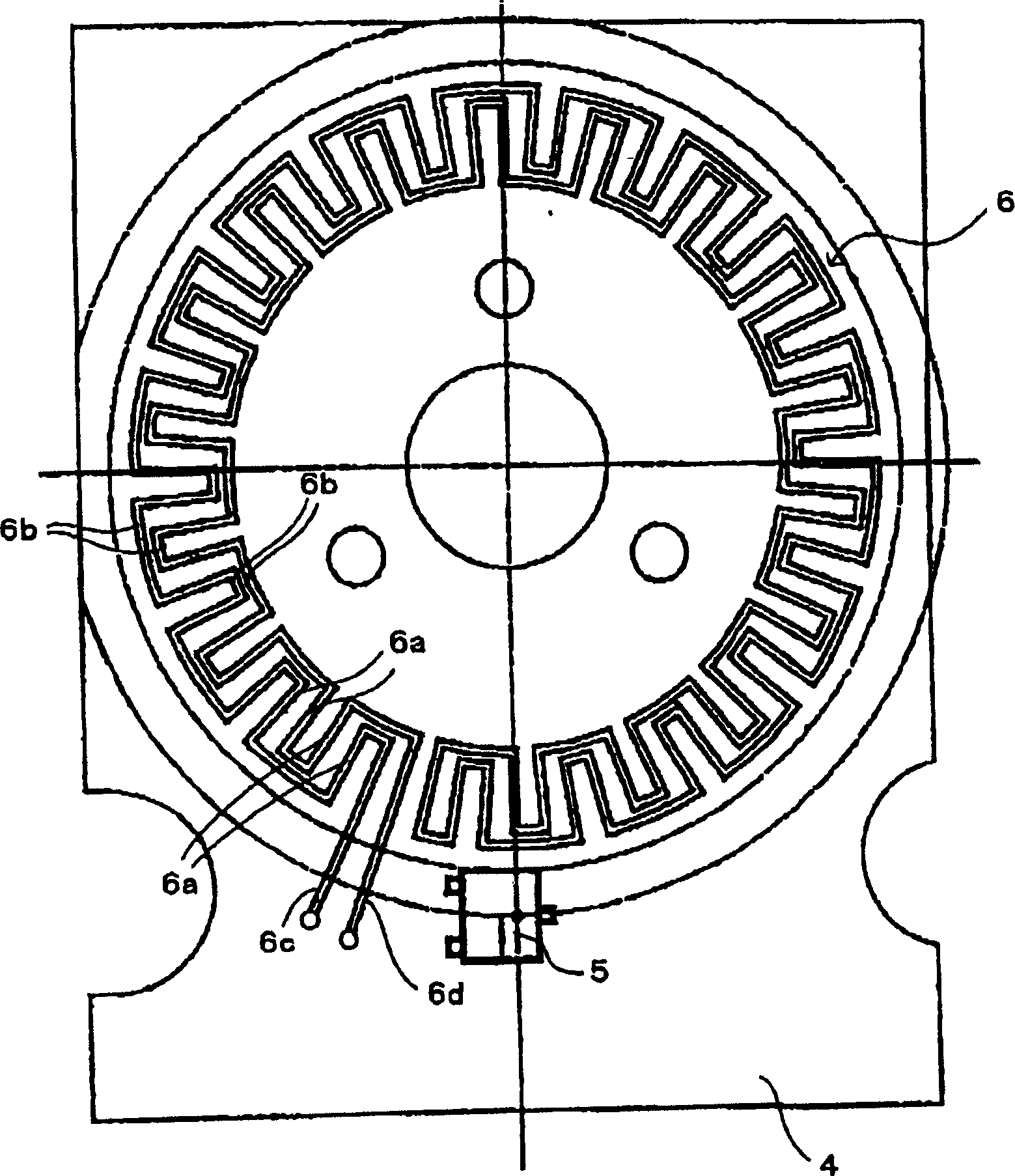

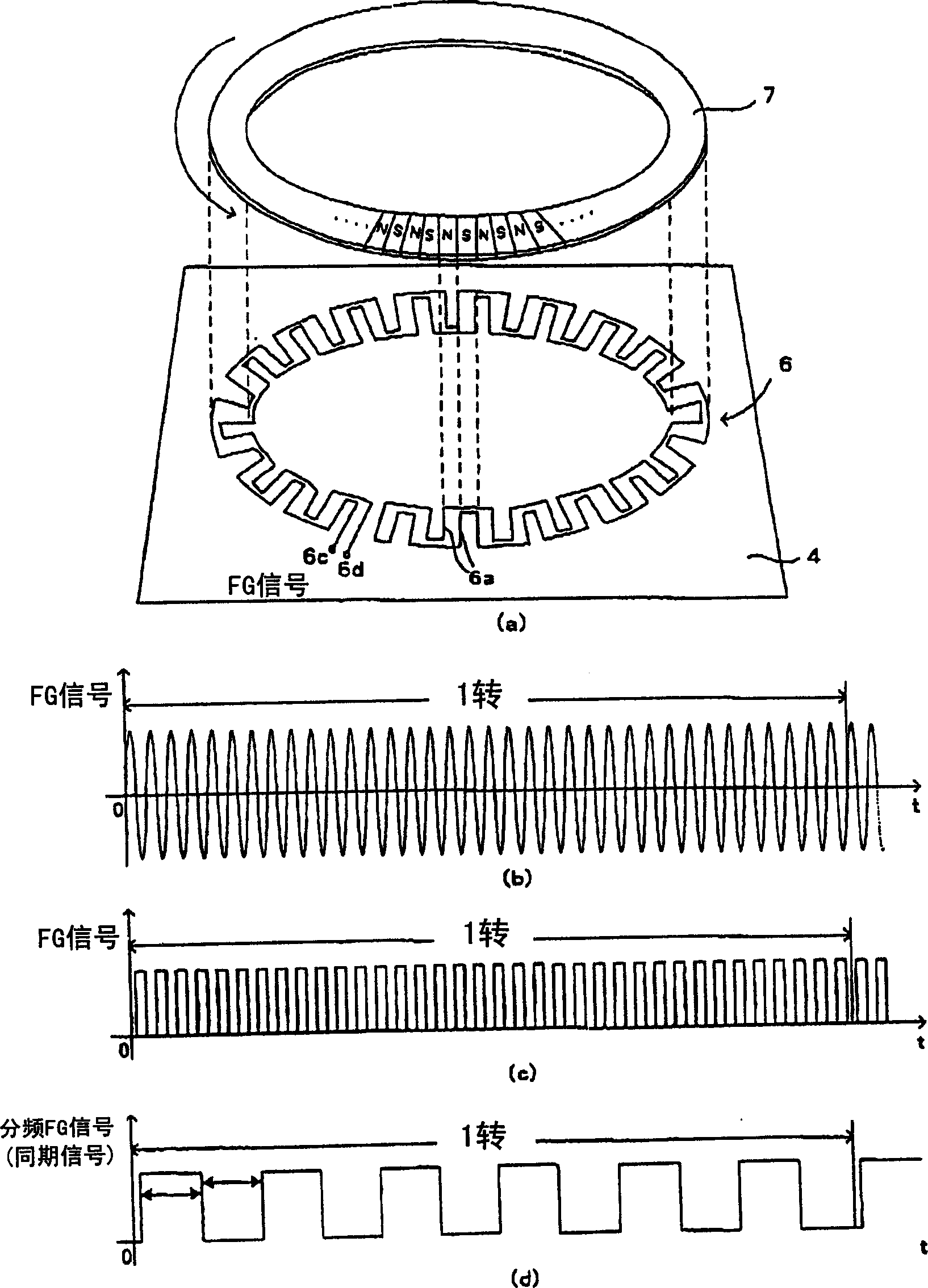

[0064] figure 1 A bearing housing 2 with a substantially cylindrical flange is mounted on the middle base plate 1 . A plurality of salient pole stator cores 3 are embedded on the outer peripheral side of the bearing seat 2 , and the stator iron cores 3 and the bearing seat 2 are fixed on the base plate 1 . The salient poles of the stator core 3 are wound with drive coils 4 for energization control.

[0065] Two bearings 16 are embedded in the inner peripheral side of the bearing housing 2, and are rotatably supported. The upper end of the rotating shaft 8 protruding from the bearing seat 2 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com