Double side display organic electroluminescence light emitting device

An electroluminescent device and double-sided display technology, which is applied in the direction of electroluminescent light source, electric light source, lighting device, etc., can solve the problems of double-sided display device structure complexity, increased thickness and weight, and increased cost, and achieve structural Simple, low manufacturing cost, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

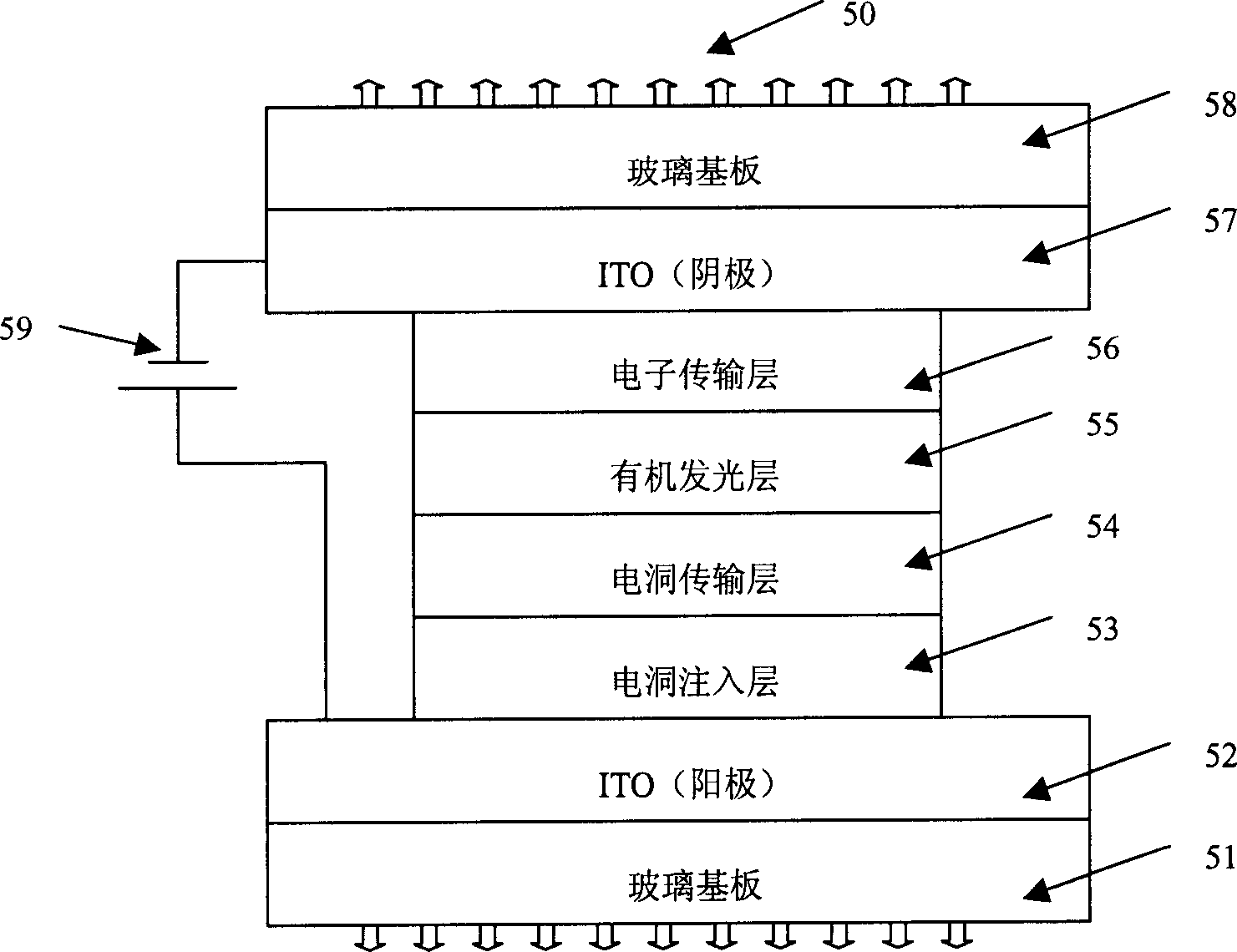

[0021] Please refer to Fig. 3, the double-sided display organic electroluminescent (Organic Light-Emitting Diode; OLED) device 50 of the present invention includes at least one transparent conductive glass (Indium-Tin Oxide; ITO) anode 52, one is opposite to this transparent ITO anode The transparent ITO cathode 57, and the organic light emitting layer (Emitting Layer; EML) 55 disposed on the ITO anode 52 and the ITO cathode 57.

[0022] The double-sided display OLED device 50 further includes a hole injection layer (Hole Injecting Layer; HIL) 53 and a hole transporting layer (Hole Transporting Layer; HTL) 54 disposed between the ITO anode 52 and the organic light-emitting layer 55, Wherein the hole injection layer 53 is adjacent to the ITO anode, the hole transport layer is adjacent to the organic light emitting layer 55; the electron transporting layer (Electron Tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com