Method of separating iron and carbon from dust setting ash

A technology for iron separation and electromagnetic separation, applied in solid separation, wet separation, chemical instruments and methods, etc., to achieve high application value and added value, simple process, and environmental improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

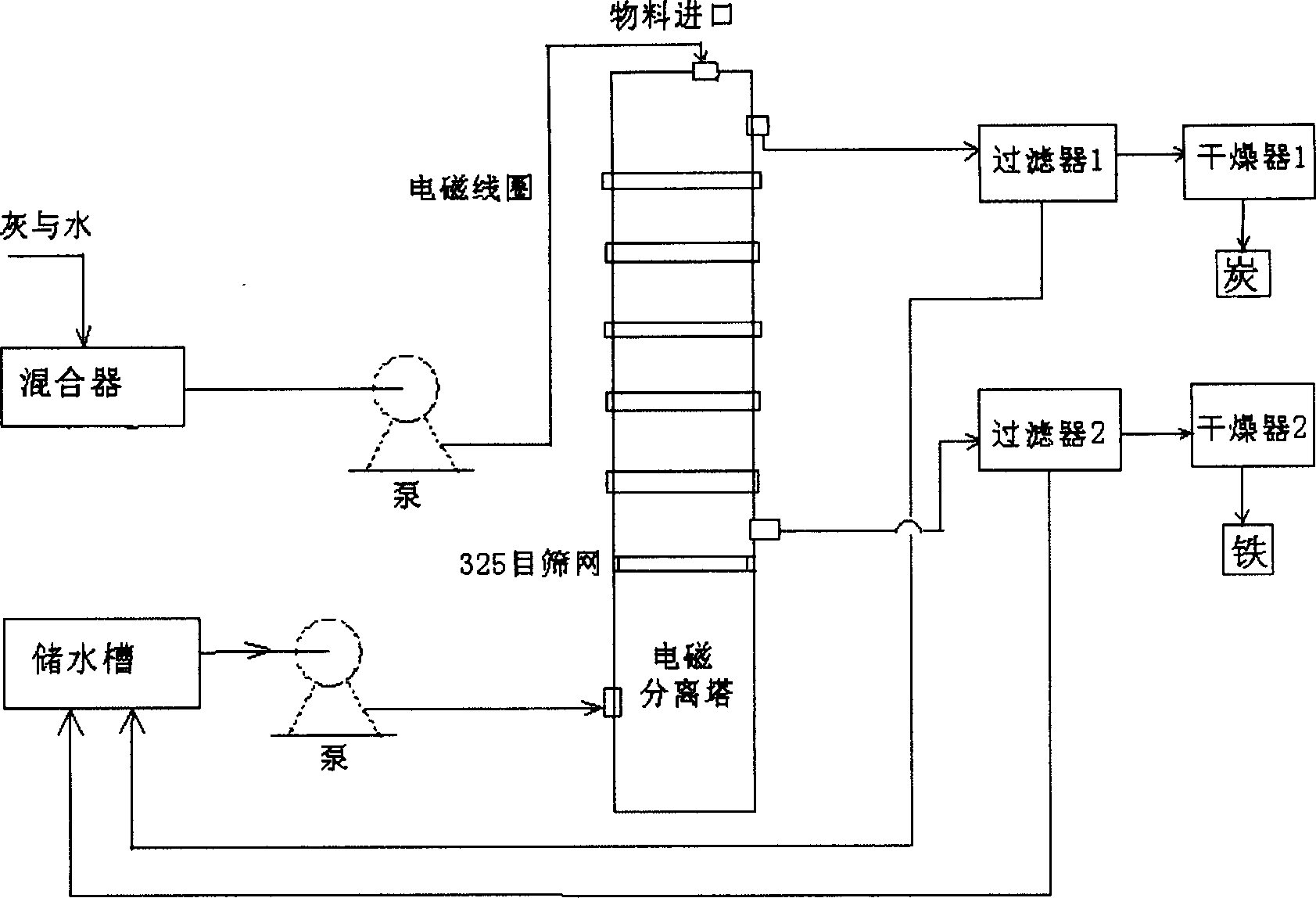

Image

Examples

example 1

[0014] Taking 1kg of dedusting ash as an example, mix the dedusting ash with water to make a suspension of 0.2kg / L, and add it from the top inlet of the electromagnetic separation tower through a pump at a flow rate of 5L / min. The tower has a diameter of 100 mm and a height of 2.5 meters, and 6 electromagnetic coils with a magnetic field strength of 300-500G (Gauss) are fixed outside it. After the feeding was completed, the water inlet was opened so that the water flow rate was 200L / h, and the magnetic field strength was controlled at 400G. The contents of iron and carbon in the samples separated at different times were shown in Table 1.

[0015] Inlet flow

example 2

[0017] The operation steps are the same as example 1. Control the influent flow rate to 200L / h, the magnetic field strength to 340 Gauss, and run for 35 minutes in the top carbon sample, the carbon mass is 290g, the iron mass is 4.5g, the iron mass in the bottom iron sample is 655g, and the carbon mass is 11.2g , the carbon content in the bottom iron sample is 1.68%.

example 3

[0019] The operation steps are the same as example 1. Control the water flow rate to 140L / h, the magnetic field strength is about 400 Gauss, and the carbon sample that runs for 50 minutes has a carbon mass of 285g and an iron mass of 2.5g. In the iron sample at the bottom of the tower, the iron mass is 680g and the carbon mass is 28.5g. The carbon content in the bottom iron sample is 4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com