Heat exchanger with single working medium for ordinary pressure

A technology of atmospheric pressure gas and heat exchangers, which is applied to the types of heat exchangers, indirect heat exchangers, lighting and heating equipment, etc., and can solve the problems of large metal consumption and bulky structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

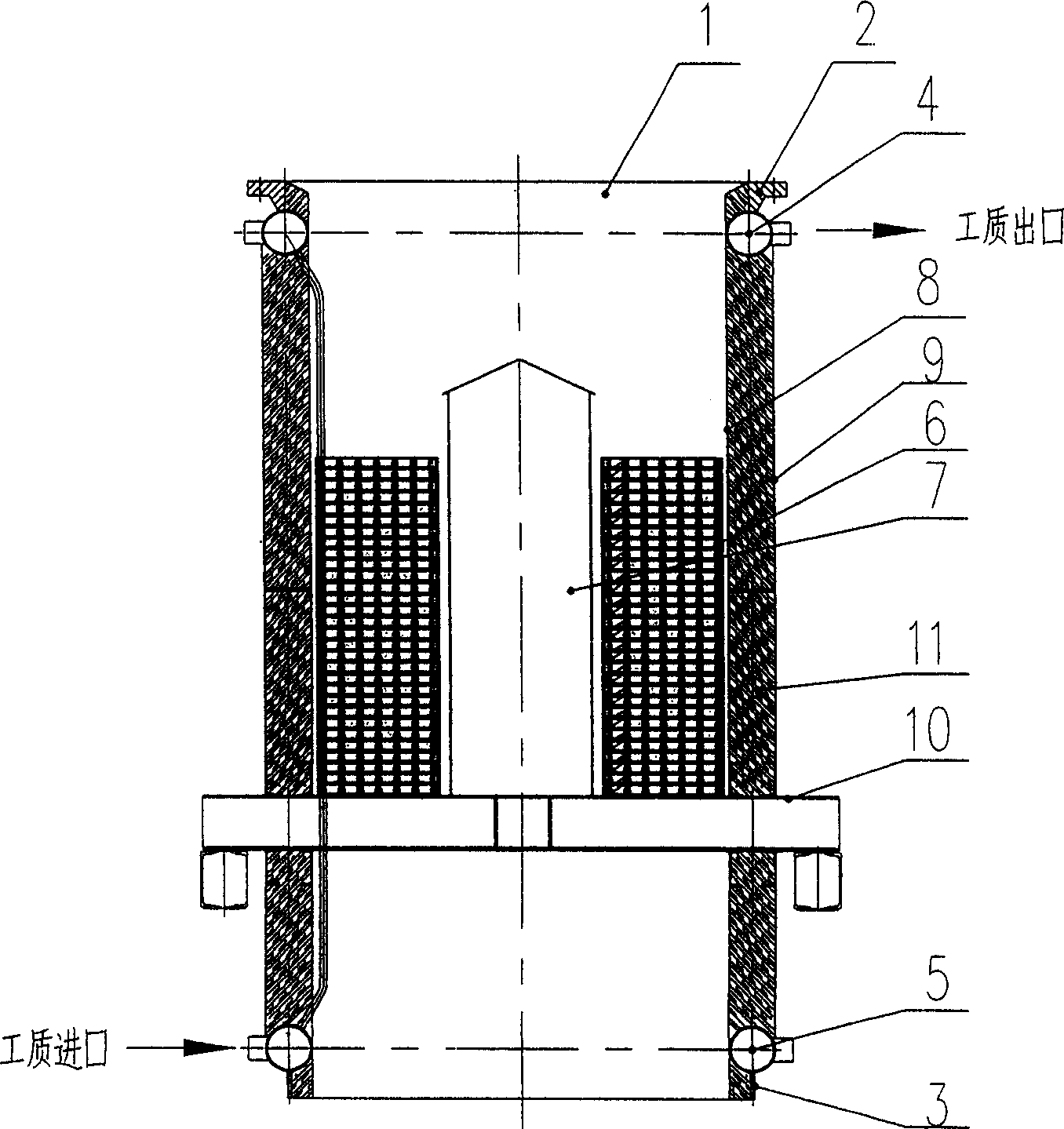

[0008] According to the operating pressure of pulverized coal gasification, it is divided into two types: normal pressure and normal pressure. This single working medium heat exchanger is the key equipment for waste heat recovery of atmospheric pulverized coal gasification and can be used as steam superheater and feed water preheater.

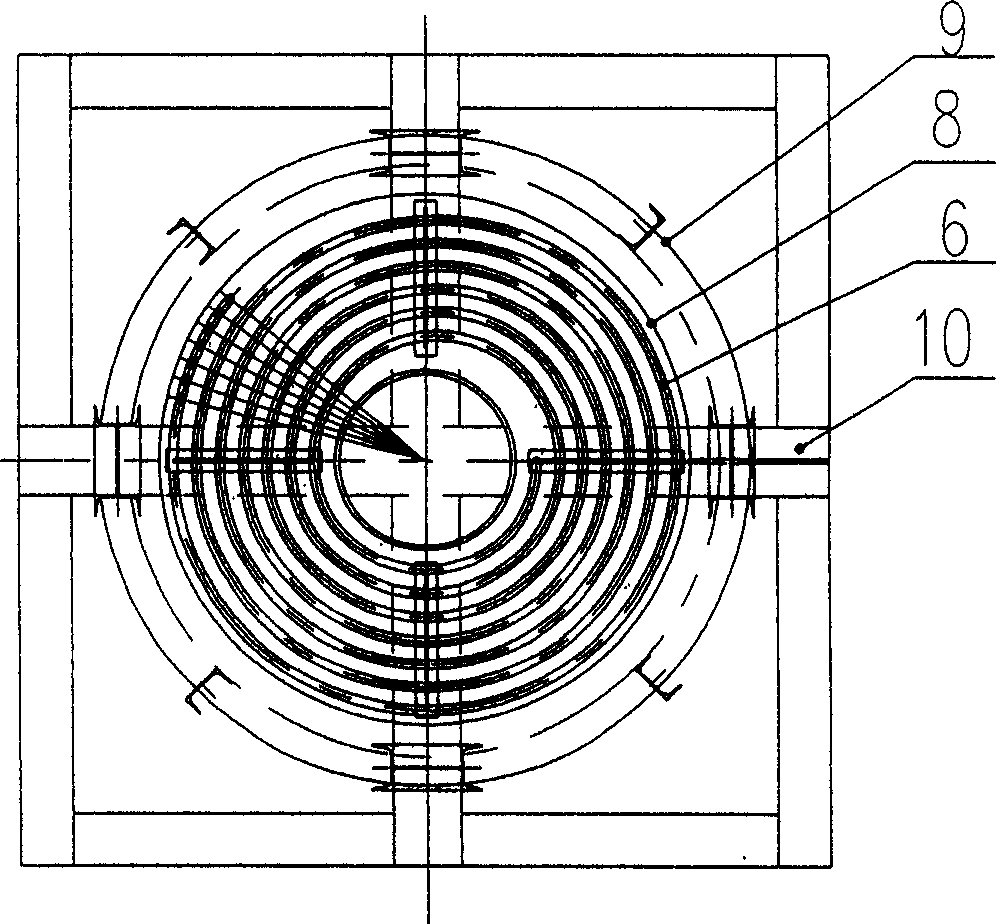

[0009] like figure 1 As shown, high-temperature gas enters the gas channel and scours the tube bundle formed by stacked coils in the gas channel. When washing the outside of the coil tubes, a process of convection and radiation heat release occurs, releasing heat and reducing the temperature; working medium- -Steam or water first enters the lower annular header, and is distributed from the lower annular header to the coils placed horizontally. When the working medium flows in the coil tube, it absorbs the heat transferred from the gas. After the temperature rises, Gather into the upper annular header and lead out through the outlet pipe. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com