Process for treating papermaking waste liquid of vapor blasting straw pulping

A technology of pulping, papermaking and straw, which is applied in the field of treating waste liquid from pulping and papermaking of steam explosion straw, can solve the problems of no better treatment methods, etc., and achieve the effect of full utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The terminology described in the present invention is explained as follows:

[0029] Aerobic: Dissolved oxygen in water.

[0030] Anaerobic: Absence of oxygen present.

[0031] BOD (Biological Oxygen Demand): The amount of oxygen required by bacteria to biologically oxidize organic pollutants in wastewater; unit: mgO 2 / l.

[0032] COD (Chemical Oxygen Demand): The amount of oxygen required to oxidize organic pollutants in wastewater.

[0033] BOD / COD ratio: This ratio indicates the biodegradability of the wastewater. The ratio of wastewater with good biodegradability is between 0.5 and 0.9.

[0034] Technical scheme of the present invention is as follows:

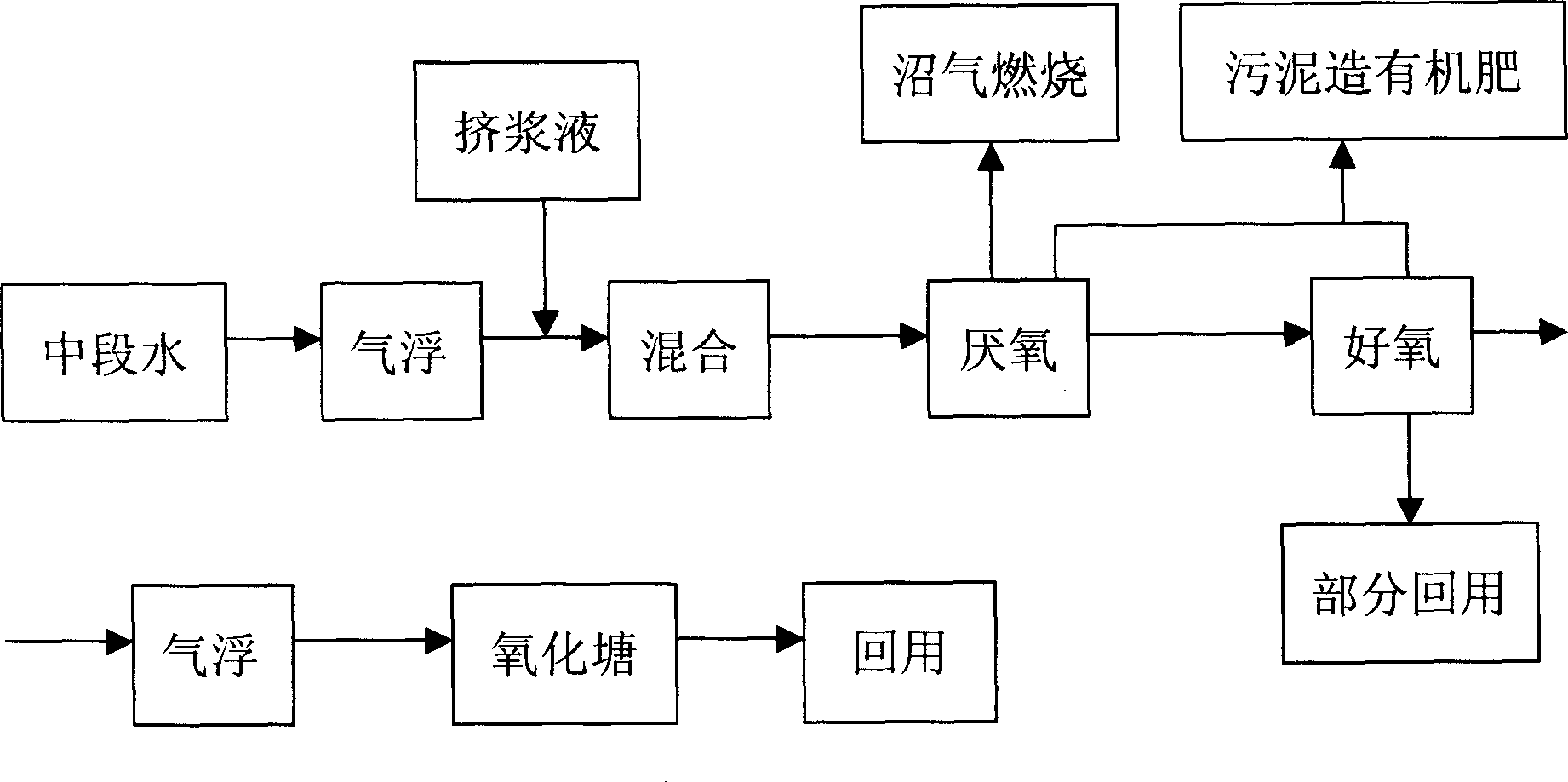

[0035] Treatment objects: steam-exploded straw pulp extract, paper-making mid-stage water.

[0036] This treatment method is mainly divided into pretreatment process, anaerobic process, aerobic process and advanced treatment process.

[0037] Pretreatment process: Firstly, the water in the middle stage of pap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com