Detection method of lithium ion battery diaphram material edge flexibility

A technology for lithium ion batteries and diaphragm materials, which is applied in the field of detection of edge curvature of lithium ion battery diaphragm materials, can solve the problems of difficult quantitative detection of rolling uniformity, and achieves short detection time, high accuracy and simple detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

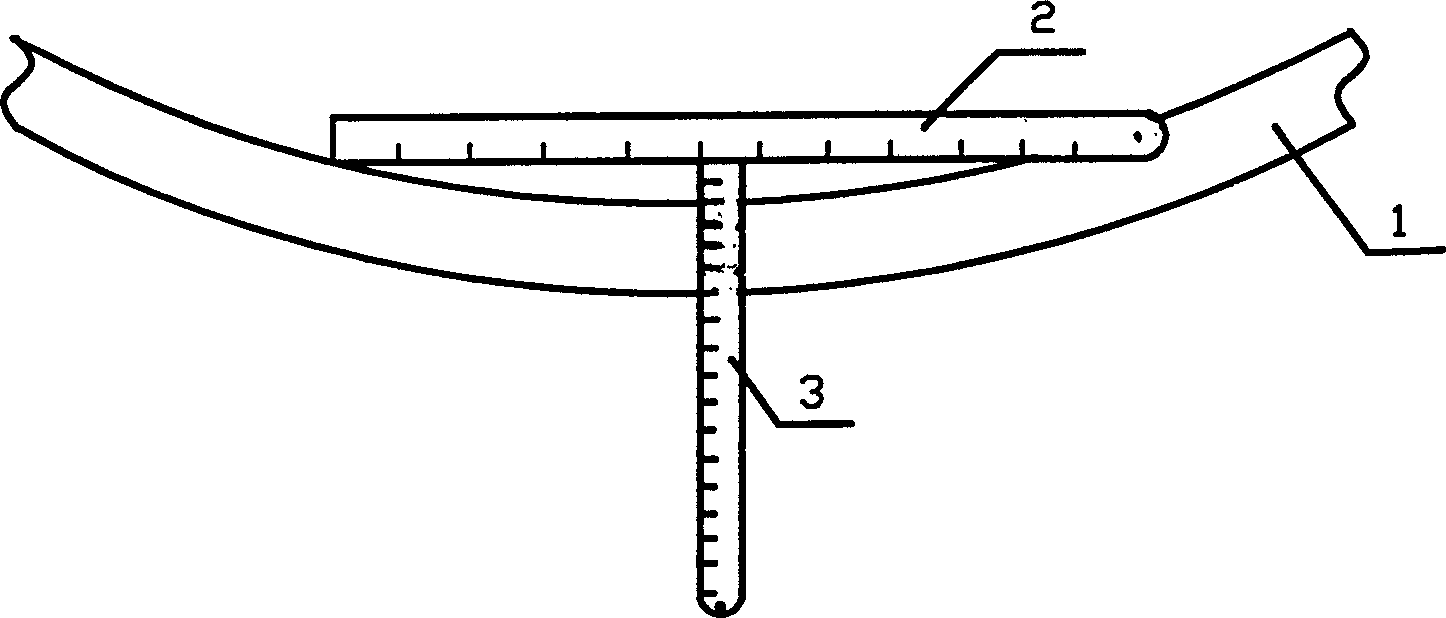

[0011] Below in conjunction with the accompanying drawings and preferred embodiments, the specific embodiments provided according to the present invention are described in detail as follows:

[0012] like figure 1 As shown, a method for detecting the edge curvature of a lithium ion battery diaphragm material is characterized in that the following steps are performed in sequence:

[0013] (1) Take a 120-200cm long diaphragm material 1 to be tested, and each diaphragm material 1 has a length greater than 20cm of the specified detection length, and spread it lightly on a smooth flat plate (such as a wooden desk surface) that does not generate electrostatic adsorption. One end (such as the left end) is pressed with a heavy object;

[0014] (2) Lightly brush several times along the length direction of the diaphragm material 1 with a soft wool brush, until the surface of the diaphragm material 1 is flat and smooth on the flat plate;

[0015] (3) Use a vertical combination of a sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com