Method for preparing potassium benzate

A technology of potassium benzoate and a manufacturing method, which is applied in the preparation of carboxylate and other directions, can solve the problems of the production technology level, the equipment level is backward, the pollution is serious, the fluidity is poor, etc., and the fluidity is good, the dust is less, and the pollution is small. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

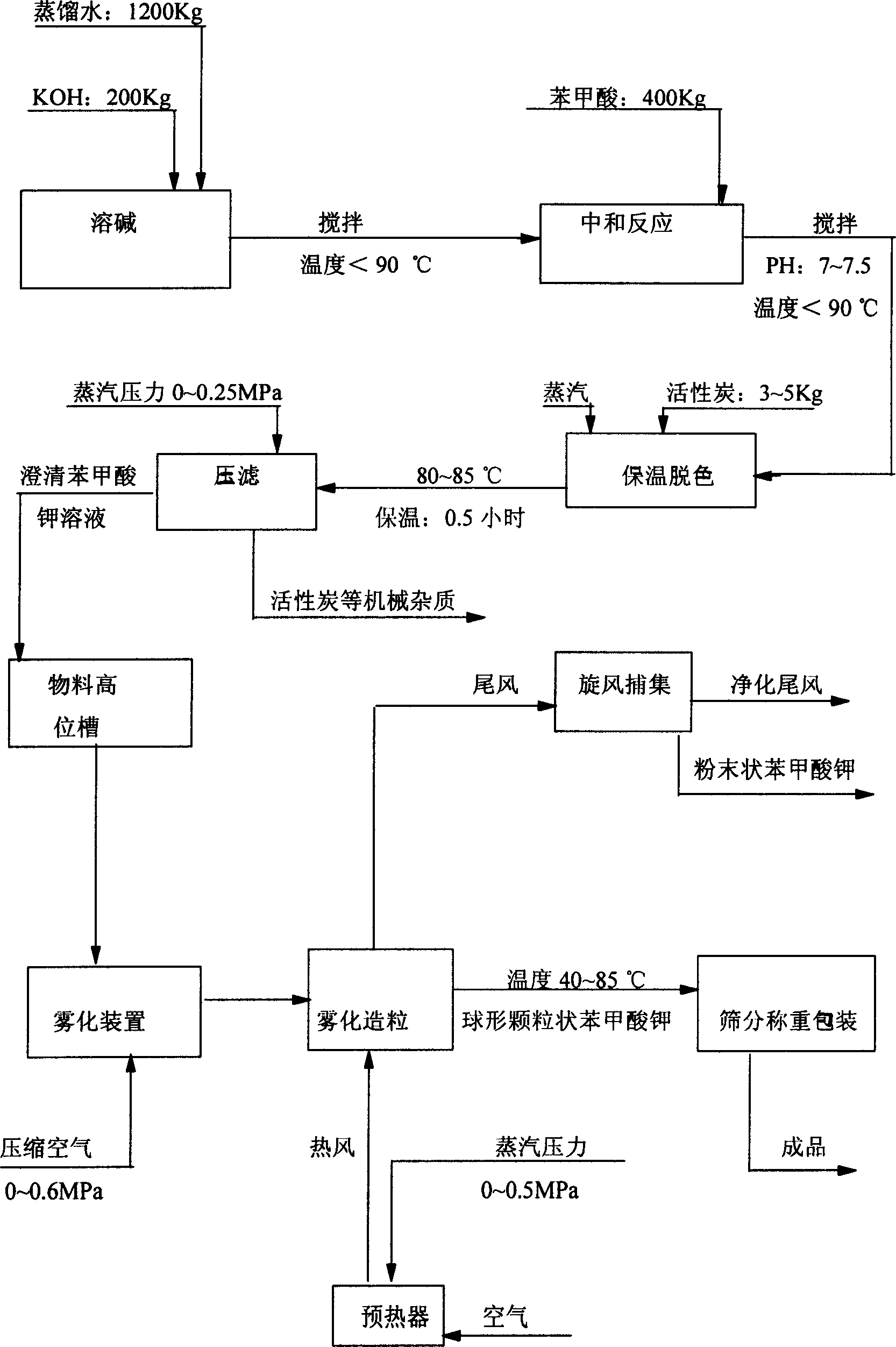

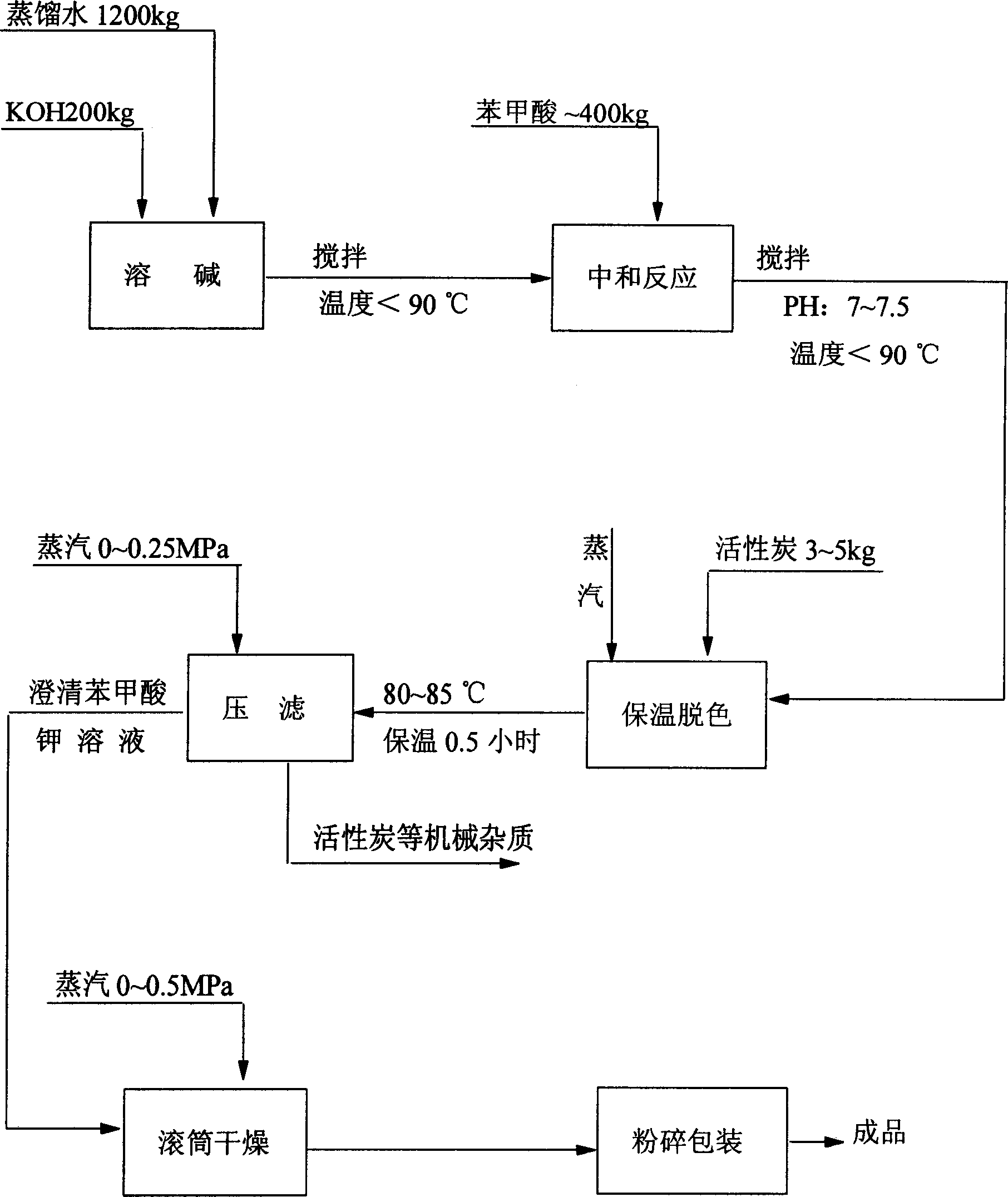

[0010] A kind of potassium benzoate manufacture method, such as figure 1 Shown, wherein include adding benzoic acid in potassium hydroxide solution with conventional method and carry out neutralization reaction to obtain common potassium benzoate reaction solution, carry out insulation decolorization to potassium benzoate reaction solution with conventional method, to the reaction solution after insulation decolorization with Conventional method carries out press filtration to obtain colorless clear and transparent potassium benzoate solution; This manufacture method also comprises atomization granulation process; The atomization granulation process comprises carrying out mist to the colorless clear and transparent potassium benzoate solution after press filtration In the common prilling tower, a certain amount of powdery potassium benzoate is used as the crystal nucleus, and the powdery potassium benzoate crystal nucleus is blown with hot air under the condition that the temp...

Embodiment 2

[0013] The potassium benzoate reaction solution after the pressure filtration in embodiment 1 is atomized, and its atomization process is: the potassium benzoate reaction solution after the pressure filtration among the embodiment 1 is blown into mist by compressed air.

Embodiment 3

[0015] The pressure of the compressed air in Embodiment 2 may be 0-0.6 MPa. In this embodiment, the pressures of the compressed air may be 0 MPa, 0.3 MPa, and 0.6 MPa respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com