Method for measuring content of dialkene in gasoline through spectrum of near infrared light

A technology of near-infrared spectroscopy and diolefins, applied in the direction of color/spectral characteristic measurement, measurement devices, and material analysis through optical means, can solve problems such as inappropriate online analysis applications, and achieve real-time monitoring, accurate prediction, and operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

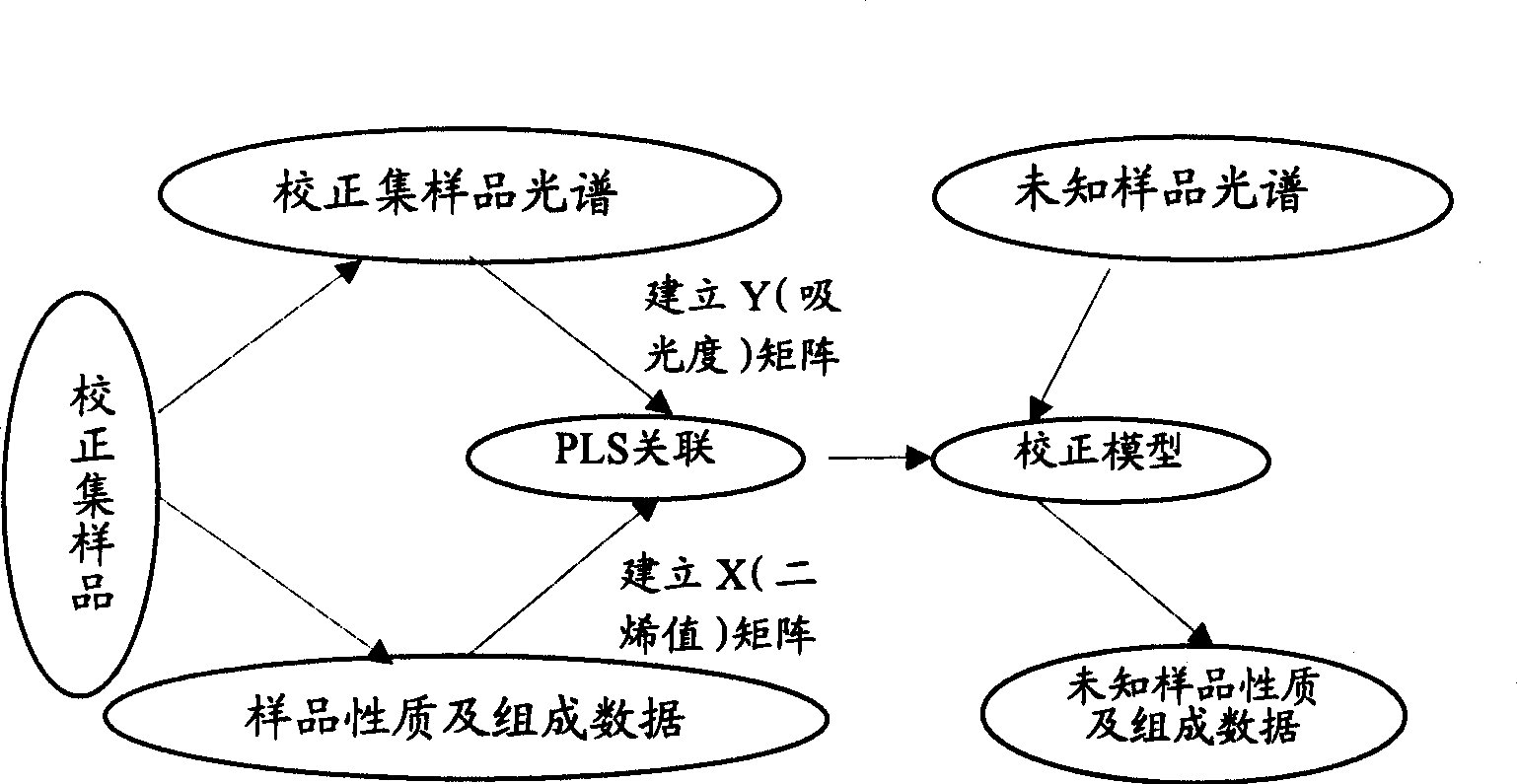

Method used

Image

Examples

example 1

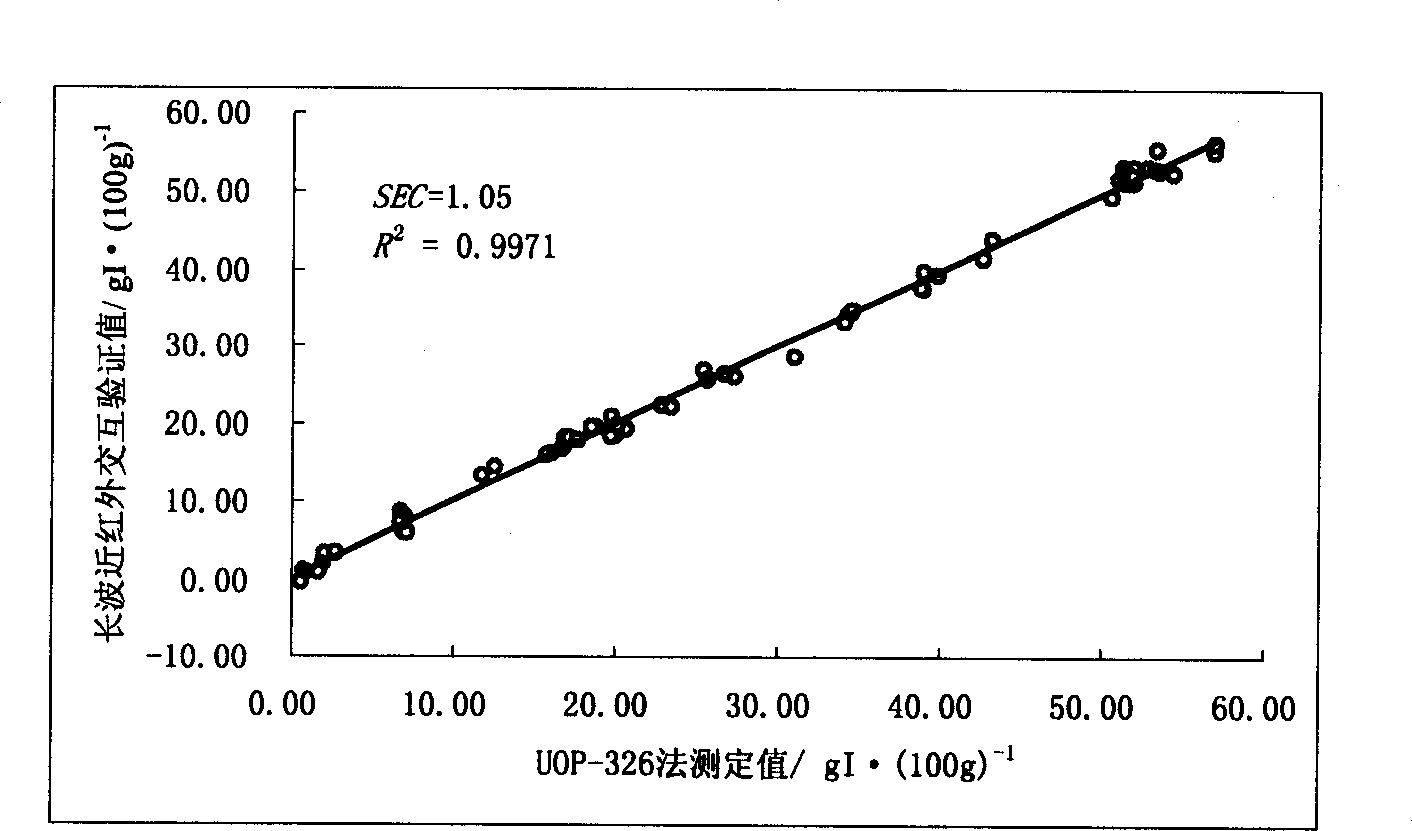

[0132] Establish and verify the calibration model of long-wave near-infrared spectroscopy.

[0133] (1) Determination of diene value content by standard method: collect 89 cracked ethylene gasoline samples from ethylene cracking unit, and use UOP-326 method to measure the diene value. Collect 66 representative samples to form the calibration set.

[0134] (2) Establish a calibration model with the samples in the calibration set: use a Bomem 160 long-wave near-infrared spectrometer (produced by Bomem, Canada) to measure the long-wave near-infrared spectrum of the samples in the calibration set. The measurement method is as follows: pour the test sample into a quartz sample absorption cell with an optical path length of 5 mm, put it in the sample cell holder for 2 minutes, and then scan the spectrum with air as a reference, and the number of scans is 16 times. Spectrum collection range: 10000~5000cm -1 ; Resolution: 4cm -1 . The measurement time for each sample was 3 minutes...

example 2

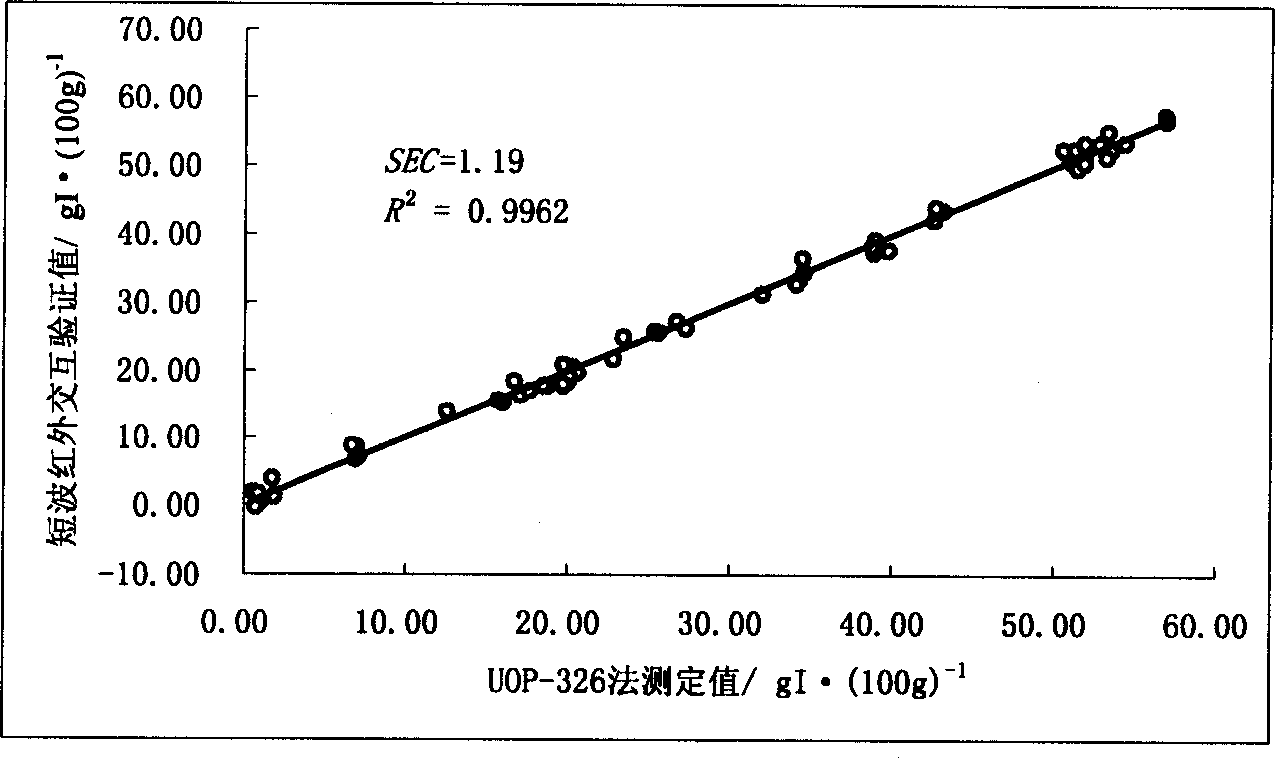

[0139] The correction model of short-wave near-infrared spectroscopy was established and verified.

[0140] (1) Determination of diene value content by standard method: collect 89 cracked ethylene gasoline samples from ethylene cracking unit, and use UOP-326 method to measure the diene value. Collect 66 representative samples to form the calibration set.

[0141] (2) Establish a calibration model using the calibration set samples: NIR-3000 short-wave near-infrared spectrometer (produced by Beijing Yingxian Instrument Co., Ltd.) measures the short-wave near-infrared spectrum of the calibration set samples. The measurement method is as follows: pour the test sample into a glass sample absorption cell with an optical path of 50 mm, put it in the sample cell rack for 3 minutes, and then scan the spectrum with air as a reference. The number of scans is 12; the temperature of the instrument is 37 ° C, The temperature of the sample cell is 25°C. Spectrum collection range: 700~1100n...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap