Open type rolling iron core and manufacturing method

A technology of winding iron core and manufacturing method, which is applied in the direction of inductance/transformer/magnet manufacturing, transformer/inductor magnetic core, electrical components, etc., can solve the problems of three-phase imbalance, transformer scrapping, winding difficulties, etc., and achieve The third harmonic component is small, the manufacturing cost is reduced, and the effect of saving winding copper materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

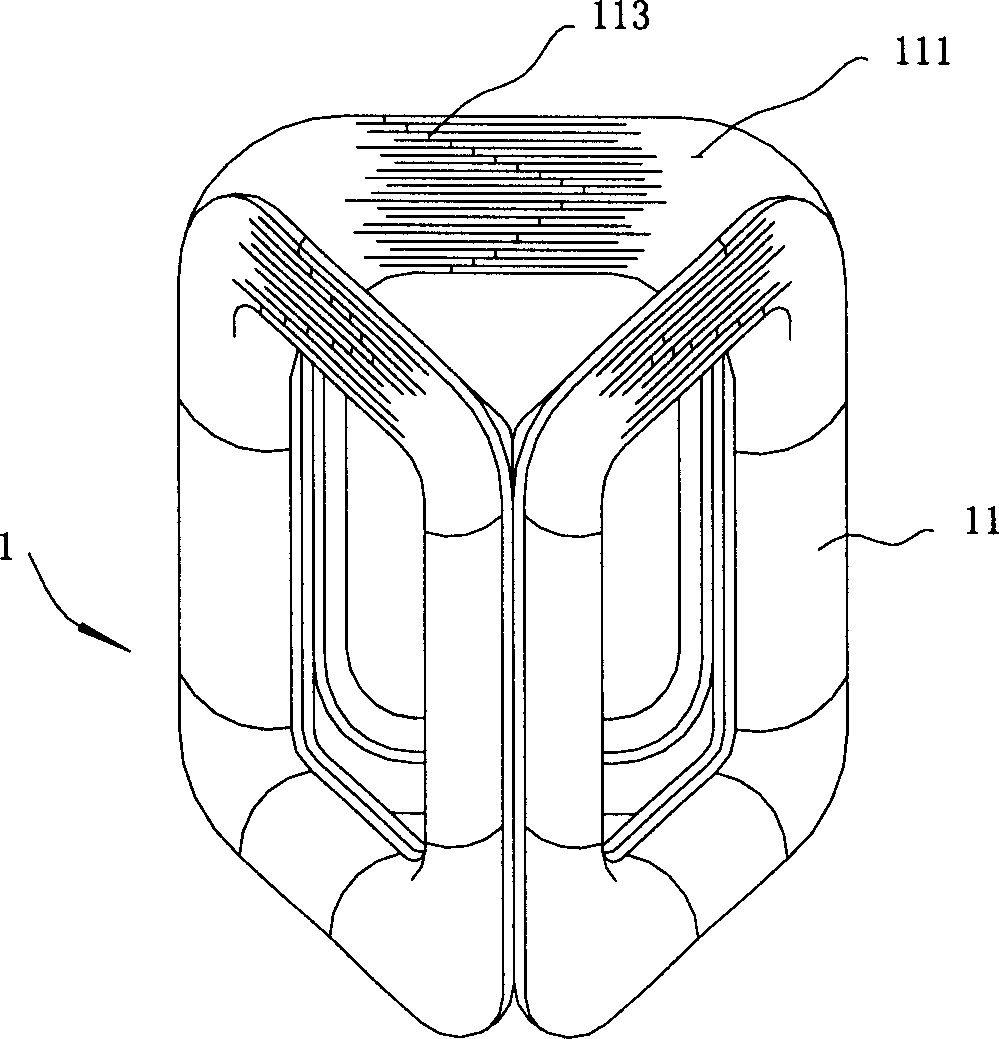

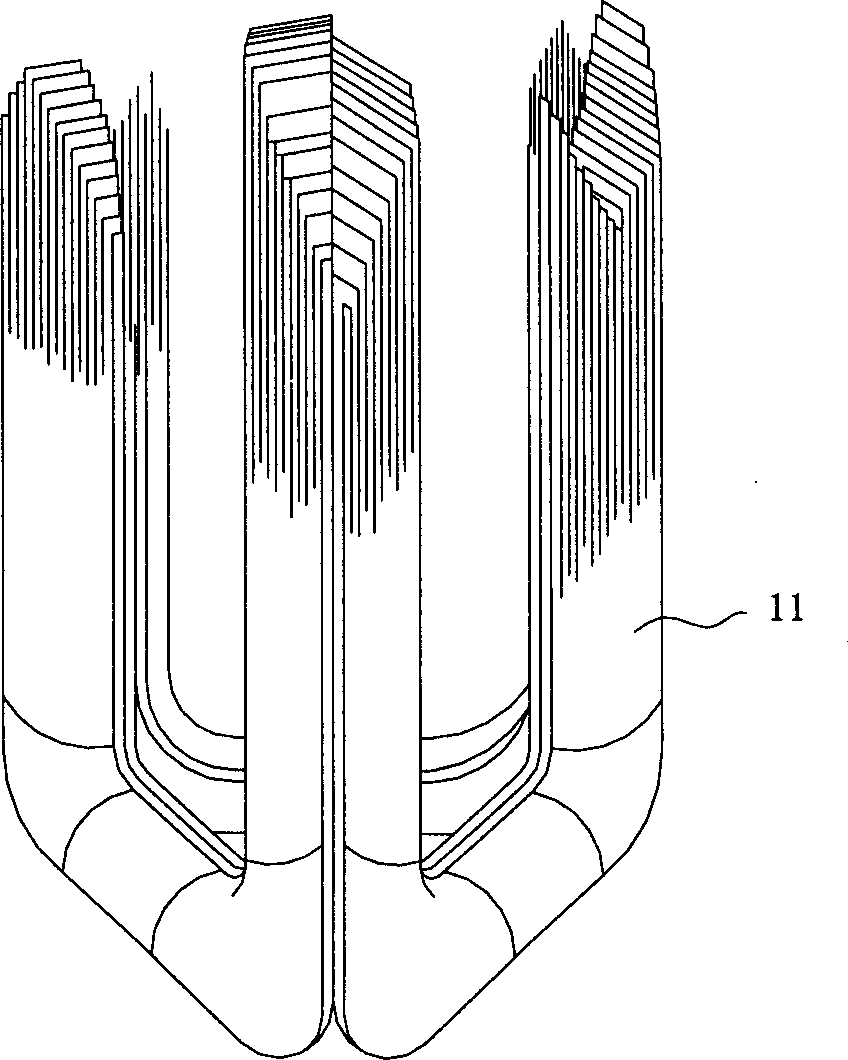

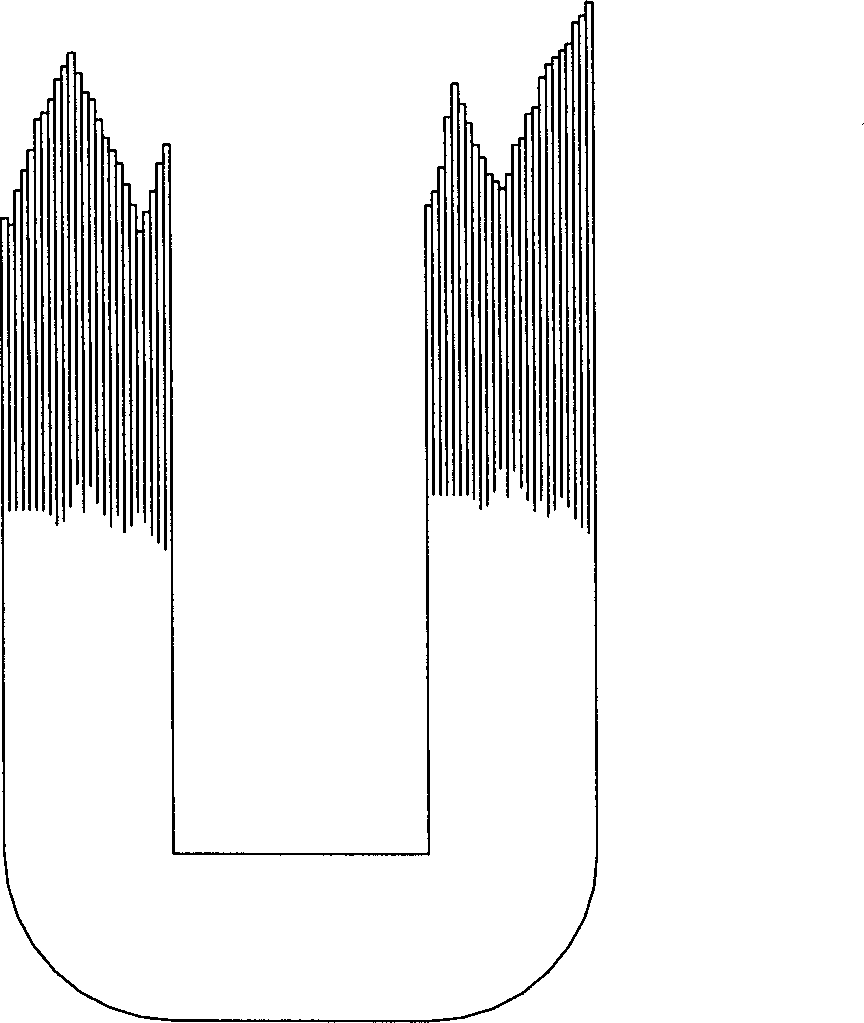

[0031] Such as figure 1 As shown, the first embodiment of the open-ended wound iron core of the present invention is a three-phase three-column three-dimensional triangular wound iron core, which is composed of three single-frame 11 iron cores with the same shape. see Figure 4~5 , each single frame is formed by winding 7 silicon steel strips of different shapes, the shape of the cross-section 112 is approximately semicircular, and grooves can be provided on the joint plane of the single frame and the single frame to form two single frame splicing There are passages that can be used for core cooling or other purposes. The cross-section of the core column formed by combining the three single frames is close to a full circle or close to a polygon.

[0032] The yoke 111 of each single frame 11 is cut in layers and dislocated to form a cutting slit consisting of a plurality of short slits 113 that are mutually staggered. The short slits 113 can be formed by cutting a layer of si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com