Toothbrush with round bead headed brush and its production process

A bristles and toothbrush technology, applied in the manufacturing process of the ball head bristles toothbrush, and the ball head bristles toothbrush field, can solve the problems of periodontal tissue nutrient metabolism disorder, incomplete removal of dirt, poor dirt removal ability, etc. The effect of reducing the number of bristles planted, saving bristle material and removing dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

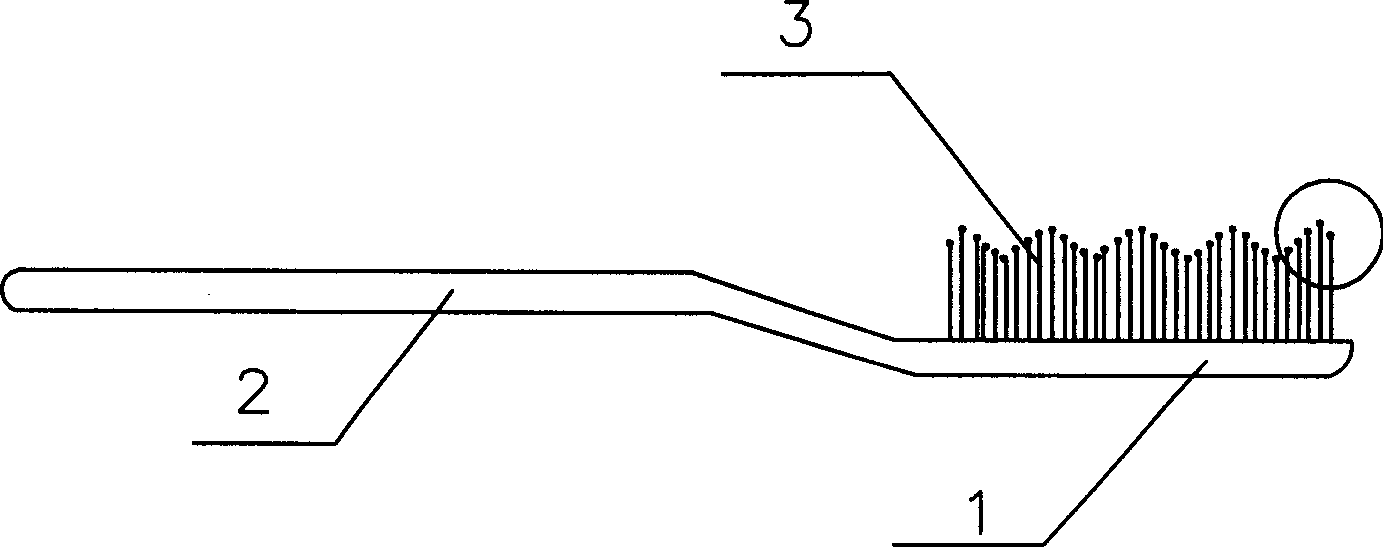

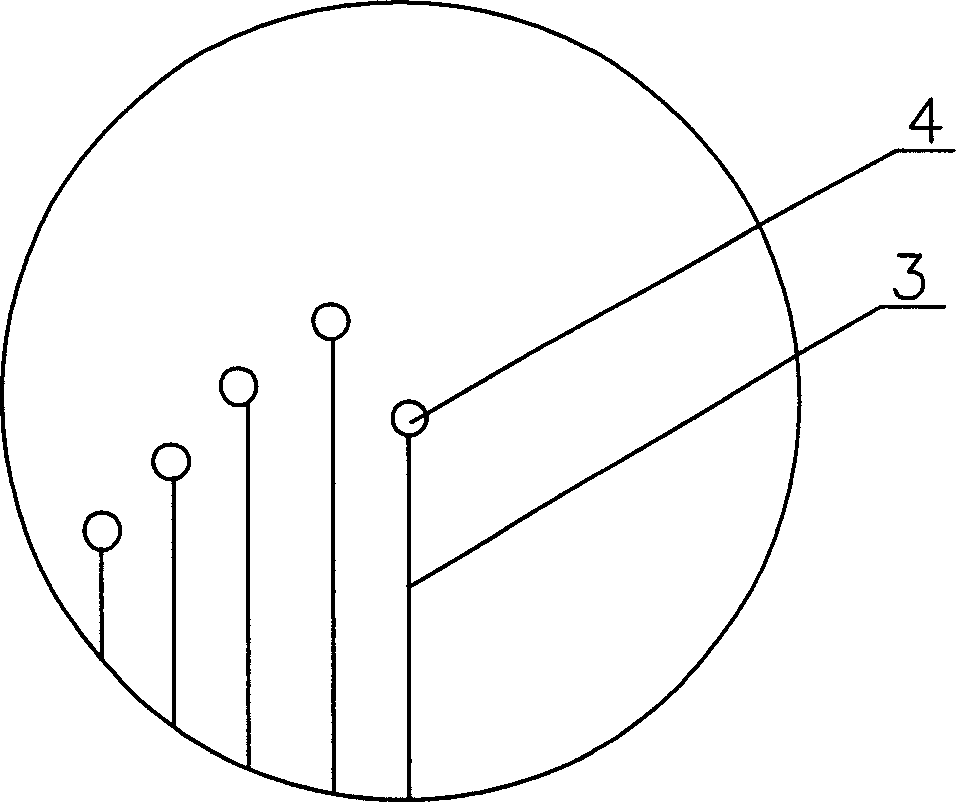

[0011] Such as figure 1 and figure 2 As shown, the toothbrush with ball head bristles includes a brush body and bristles 3. The brush body is composed of a brush head 1 and a brush handle 2 connected to one end of the brush head 1. The base ends of the bristles 3 are fixed on the brush head 1 in bundles. The bristles 3 are processed by sanding technology, and their shape is cylindrical with a diameter of 0.21 mm. The front end of the bristles 3 is in the shape of a ball 4 with a diameter of 0.29 mm. The number of bristles 3 per bundle is 28, which is higher than that of existing toothbrushes. The number of hair transplants has been reduced by about 25%, which greatly reduces the cost.

[0012] The manufacturing process of the ball head bristle toothbrush is as follows: the bristles 3 made of domestic 610 nylon filaments are fixed on the brush head 1 of the formed brush body, the bristles 3 are shaped, and at room temperature, the front ends 4 of the bristles 3 are placed at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com