Preparation method of wheat syrup for beer brewing

A wheat and syrup technology, which is applied in beer brewing, wort preparation, biochemical equipment and methods, etc., can solve problems such as affecting beer fermentation and lack of nitrogen sources in corn syrup, and achieve lower production costs, pure taste, and better beer. Good foaming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

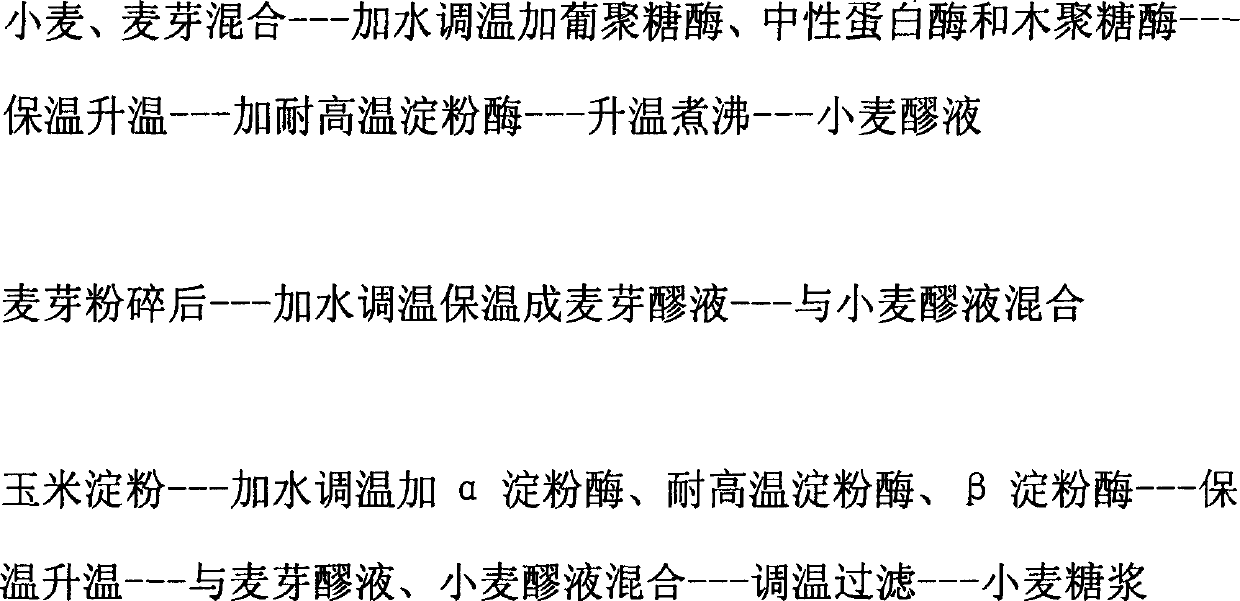

Image

Examples

Embodiment Construction

[0012] Taking the preparation of 100kl beer brewing wheat syrup as an example:

[0013] A. Grind and mix 7000kg wheat and 1260kg malt into No. 1 pot, add 29000kg water, adjust the temperature to 45°C, add 11kg glucanase, 9kg neutral protease and 5kg xylanase, mix and keep warm for 1 hour, Heat up to 50°C for 2 hours, heat up to 62.5°C for 8 hours, add 1.5kg of high-temperature-resistant amylase, heat up to 68°C for 15 minutes, heat up to 80°C for 20 minutes, heat up to 100°C and boil for 15 minutes to form wheat mash.

[0014] B. Crush 2940kg of malt and put it into No. 2 pot, add 10500kg of water, adjust the temperature to 45°C and keep it warm for 20 minutes, raise the temperature to 50°C and keep it warm for 1 hour to form malt mash, mix it with No. 1 pot of wheat mash, add 1kg of Glucose For carbohydrase, adjust the temperature to 63°C and keep it warm for 30 minutes, then raise the temperature to 68°C and keep it warm for 40 minutes.

[0015] C. Put 2800kg of cornstarch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com