Quickflashing memory unit manufacturing method

A storage unit and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as influence, poor quality of gate oxide layer, and limitation of surface cleaning steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The method of the present invention will be described in detail according to the following preferred embodiment and with reference to the accompanying drawings.

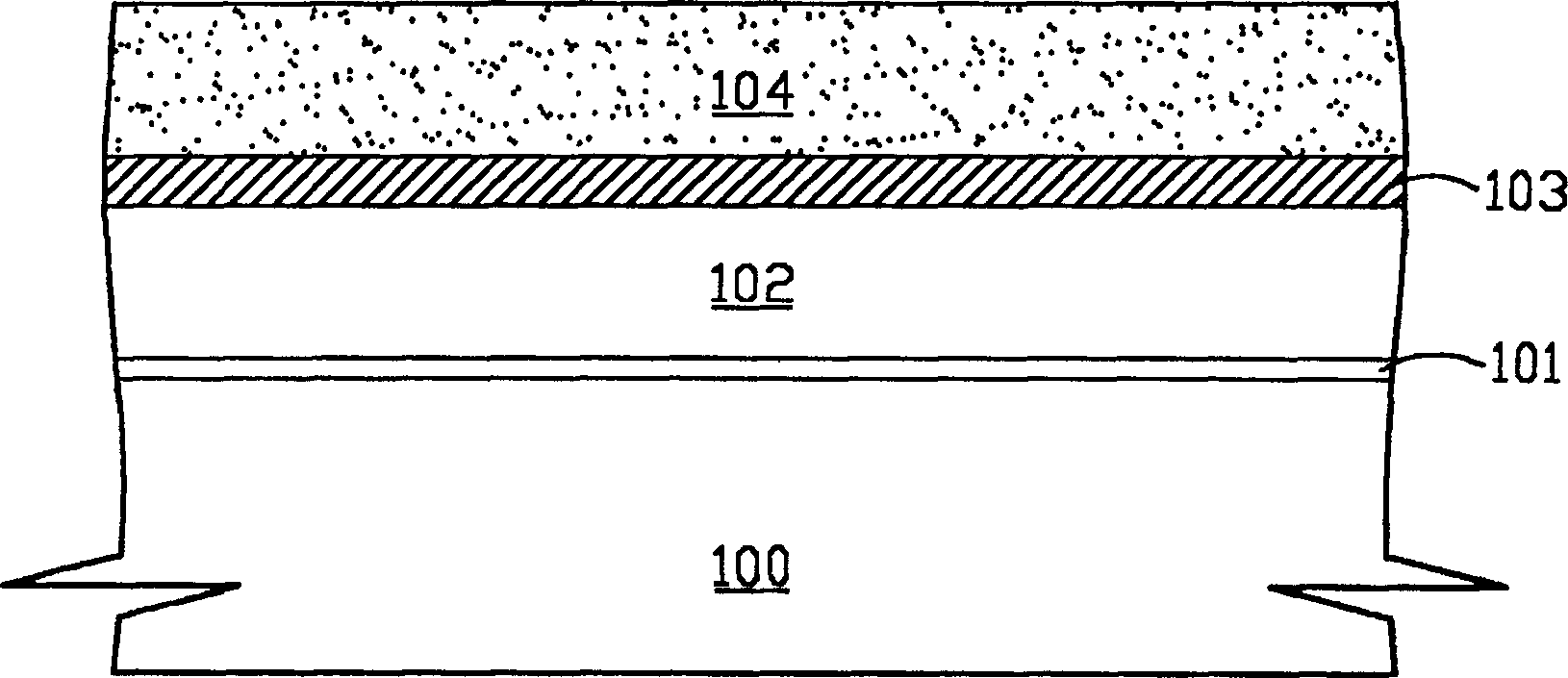

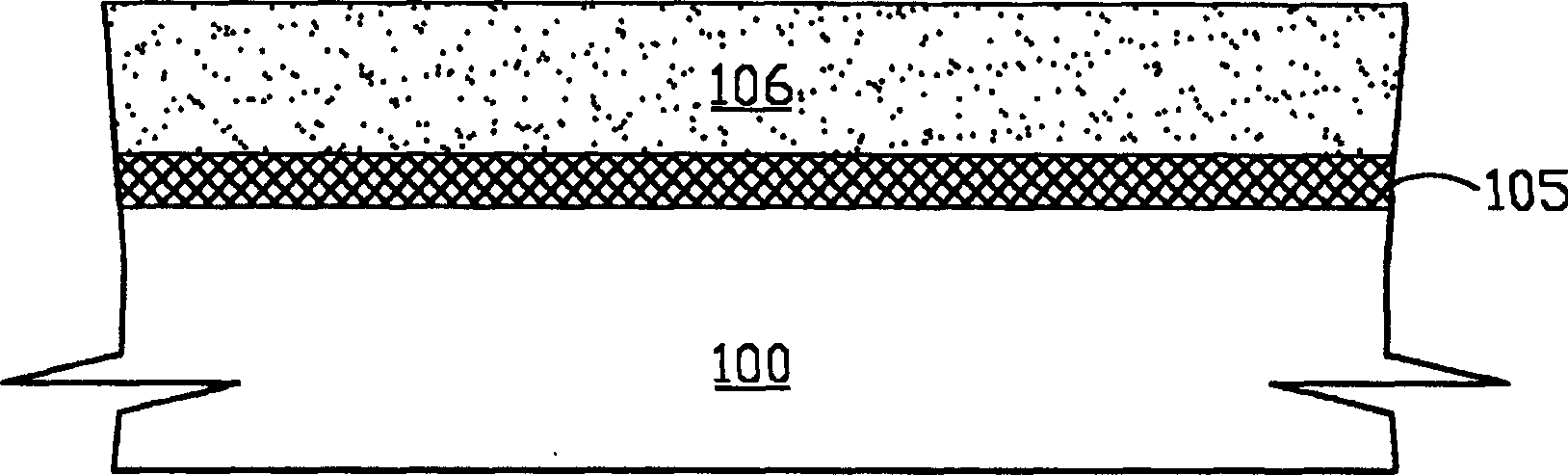

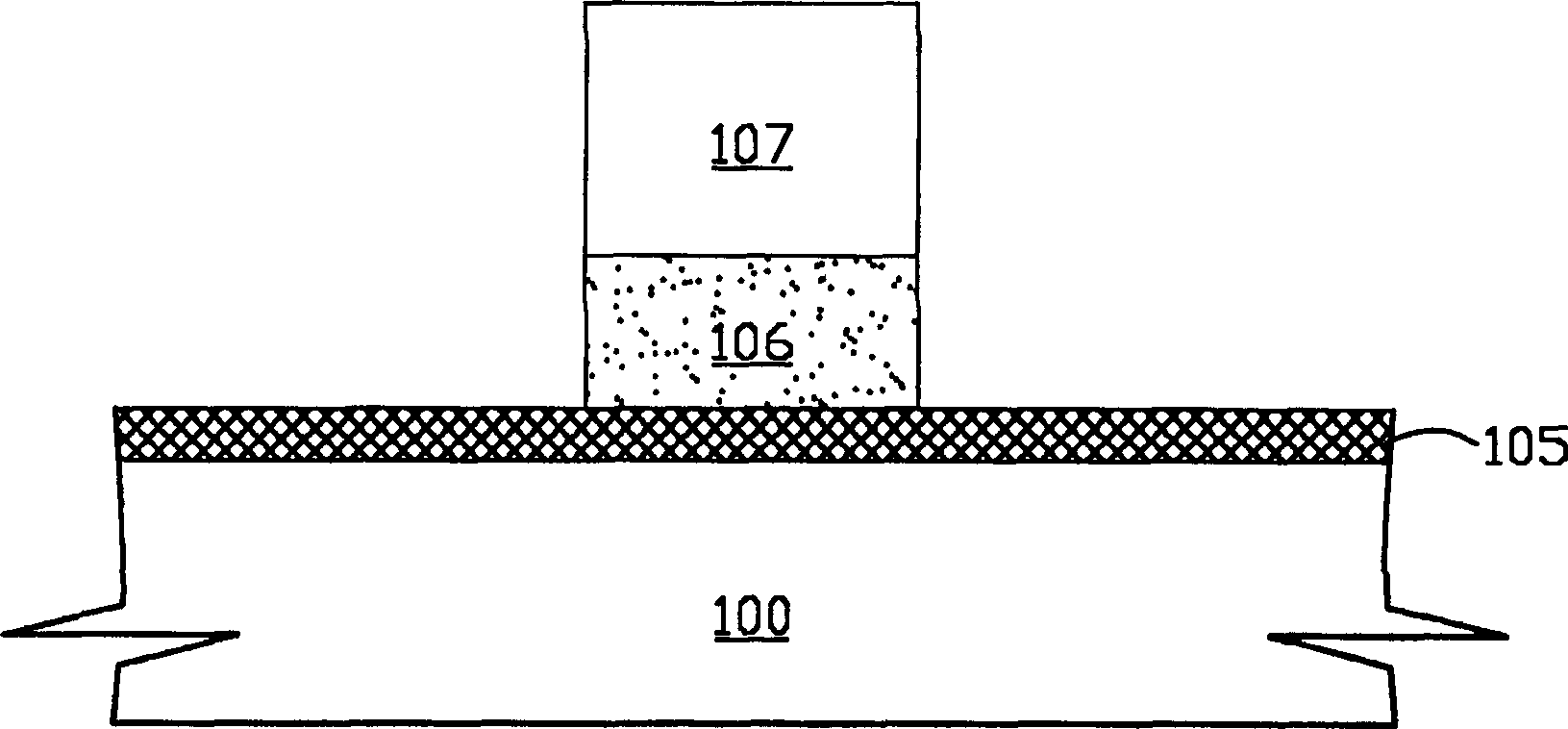

[0016] A preferred embodiment of the invention is shown in Figure 1A to Figure 1D and Figure 2A to Figure 2E ,in Figure 1A to Figure 1D It is a schematic cross-sectional view of various formation steps of the peripheral region (periphery region) of the flash electrically erasable and programmable read-only memory unit of the present invention, and Figure 2A to Figure 2E It is a schematic cross-sectional view of various formation steps of the memory cell region of the flash electrically erasable and programmable read-only memory unit of the present invention.

[0017] refer to Figure 1A and Figure 2A , a tunnel oxide layer 101 is formed on a semiconductor substrate 100 with a first conductivity. The semiconductor substrate 100 can be an N-type or P-type substrate, preferably a P-type silicon substrate....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com