Electrophoretic dipping system

A dip coating and equipment technology, applied in electrolytic coatings, electrophoretic plating, coatings, etc., can solve the problems of damage to the durability of the dialysis unit, expensive and heavy smooth choke coils, etc., to improve the coating effect, prevent The effect of electrostatic field entering the interior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

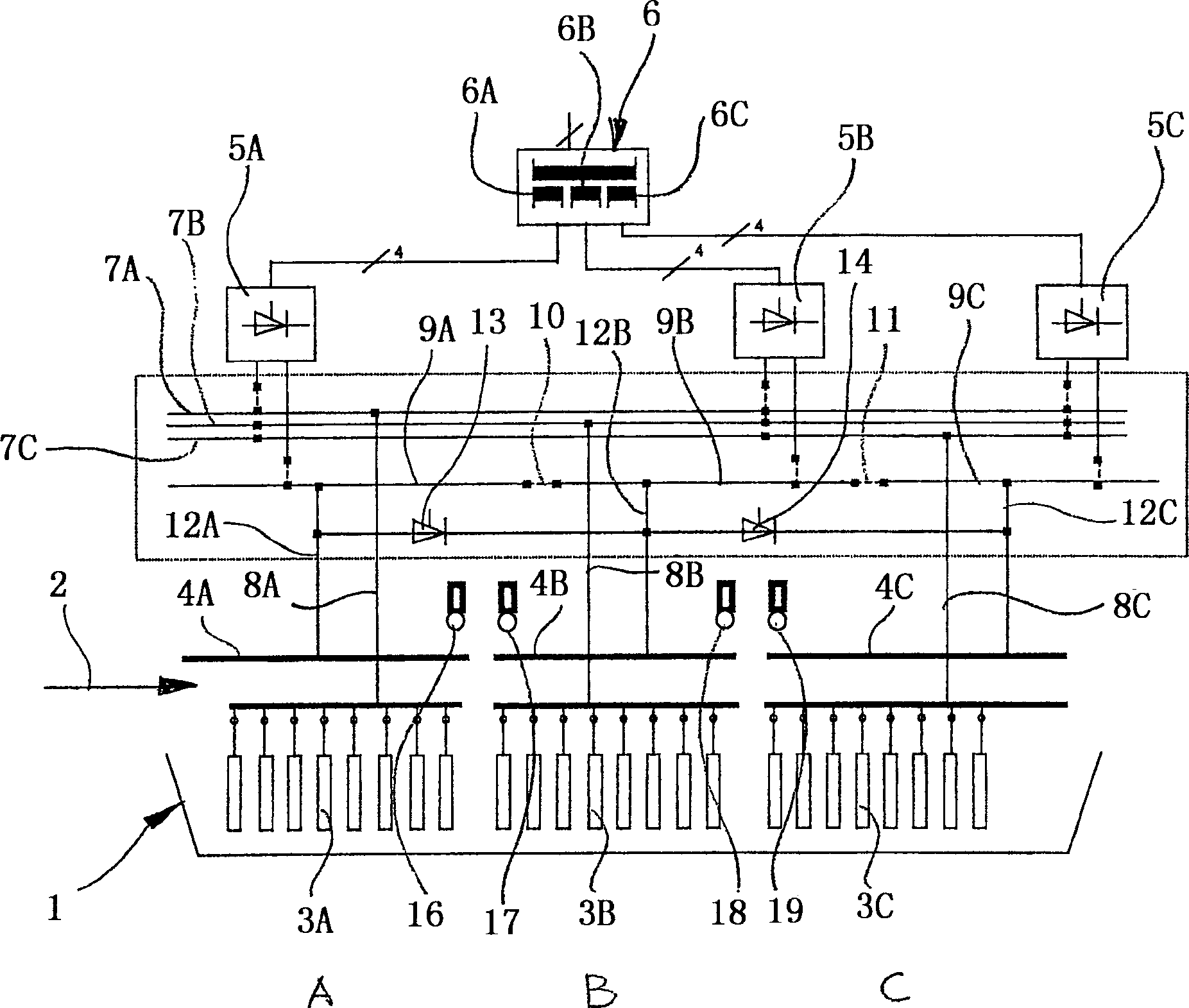

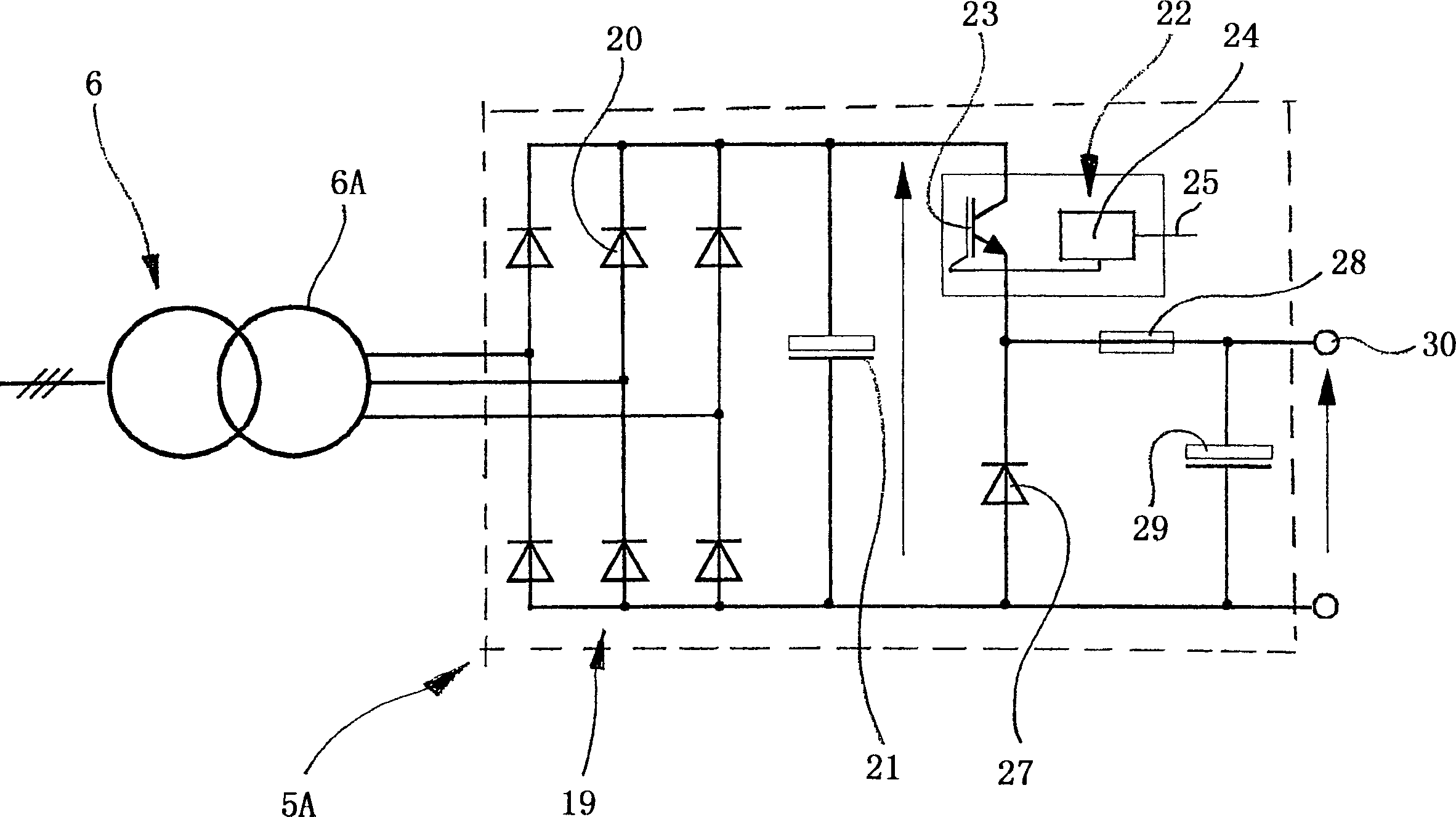

[0025] First refer to figure 1 . In this figure, reference numeral 1 indicates a dipping tank, which is filled with liquid paint during operation. The object to be painted, for example a motor vehicle body, is immersed in this dipping bath 1 . This can be done in a continuous pass method, in which the objects to be coated are mounted on a conveyor which moves the objects into, through and out of the dip coating tank 1 . Alternatively, however, the object can also be coated in the dipping tank 1 by the takt-Tauchverfahren method. For the purposes of the following description, a continuous pass method is assumed; the direction of movement of the object to be painted is indicated by arrow 2 .

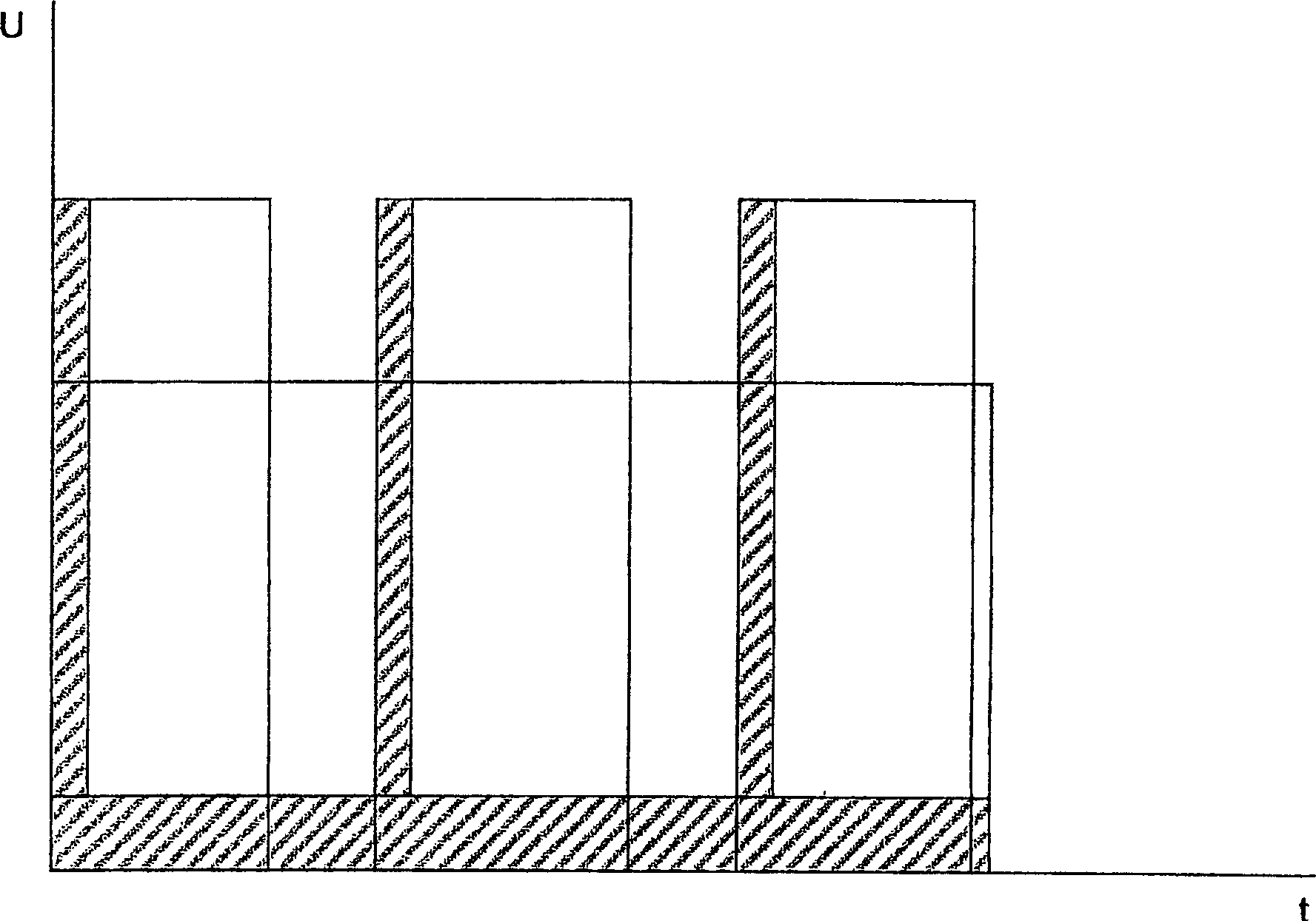

[0026] For depositing paint particles, such as pigments, binders and filler particles, contained in a liquid paint, the surface of the object is brought to the cathodic potential of an electric field established between a plurality of anodes 3 and the surface of the object as it passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com