Completely hydraulically driven breaking dredger

A traveling, fully hydraulic technology, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems that the dumper cannot unload coal normally, the machine cannot be returned to the machine room, and can only stop on the coal grate, etc., reaching the weight Lightweight, smooth running, and less maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

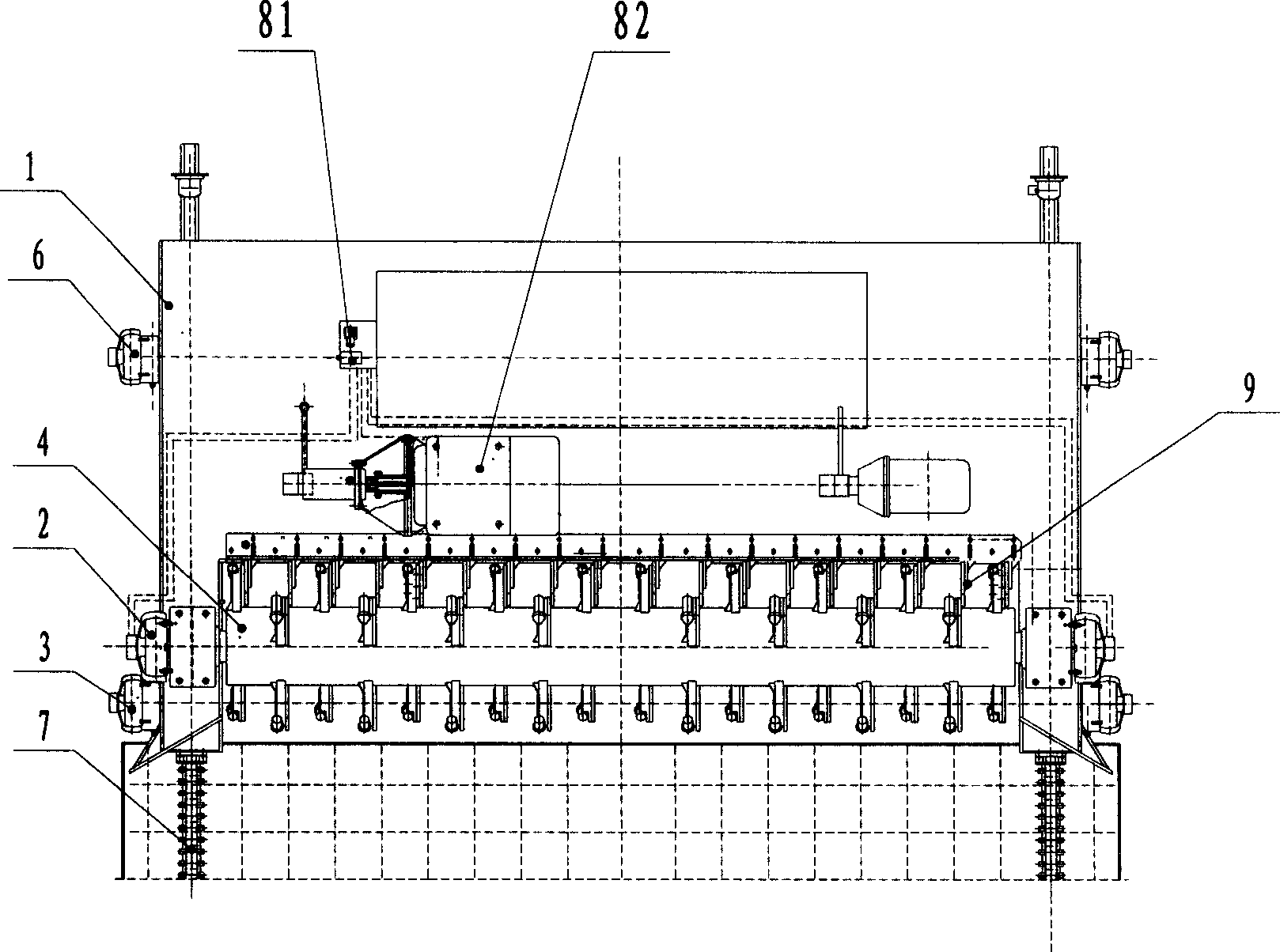

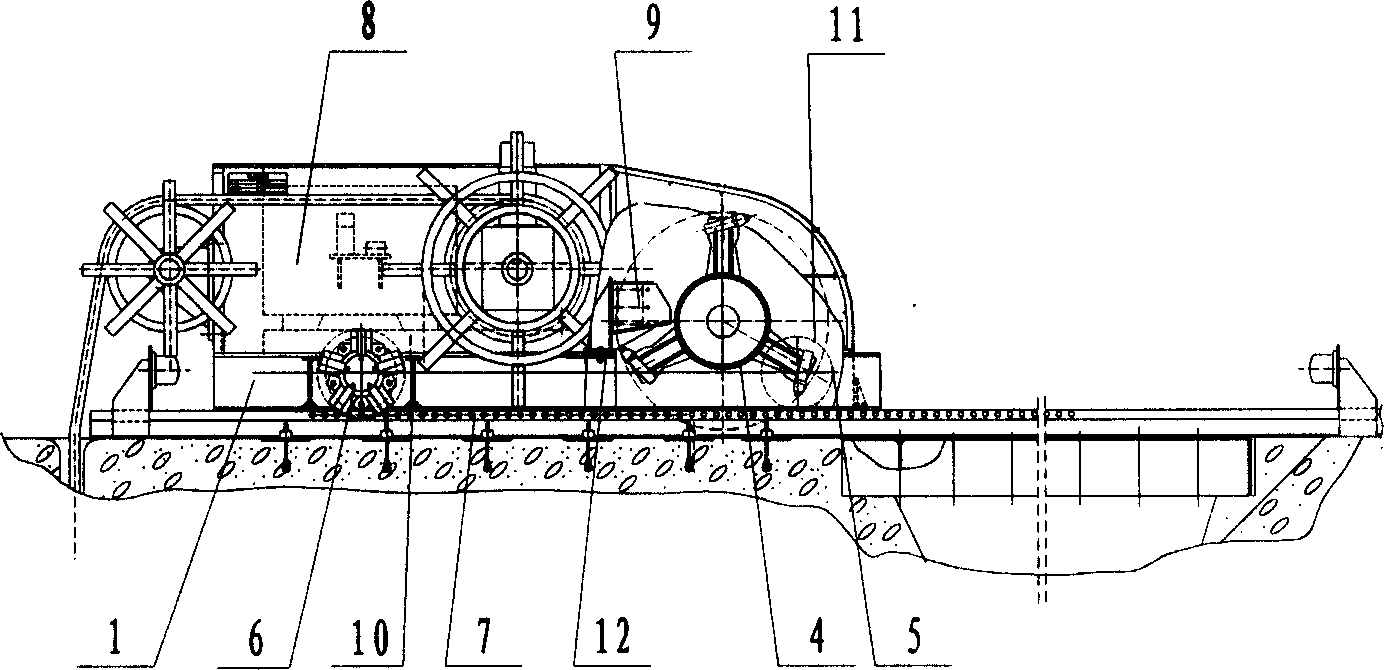

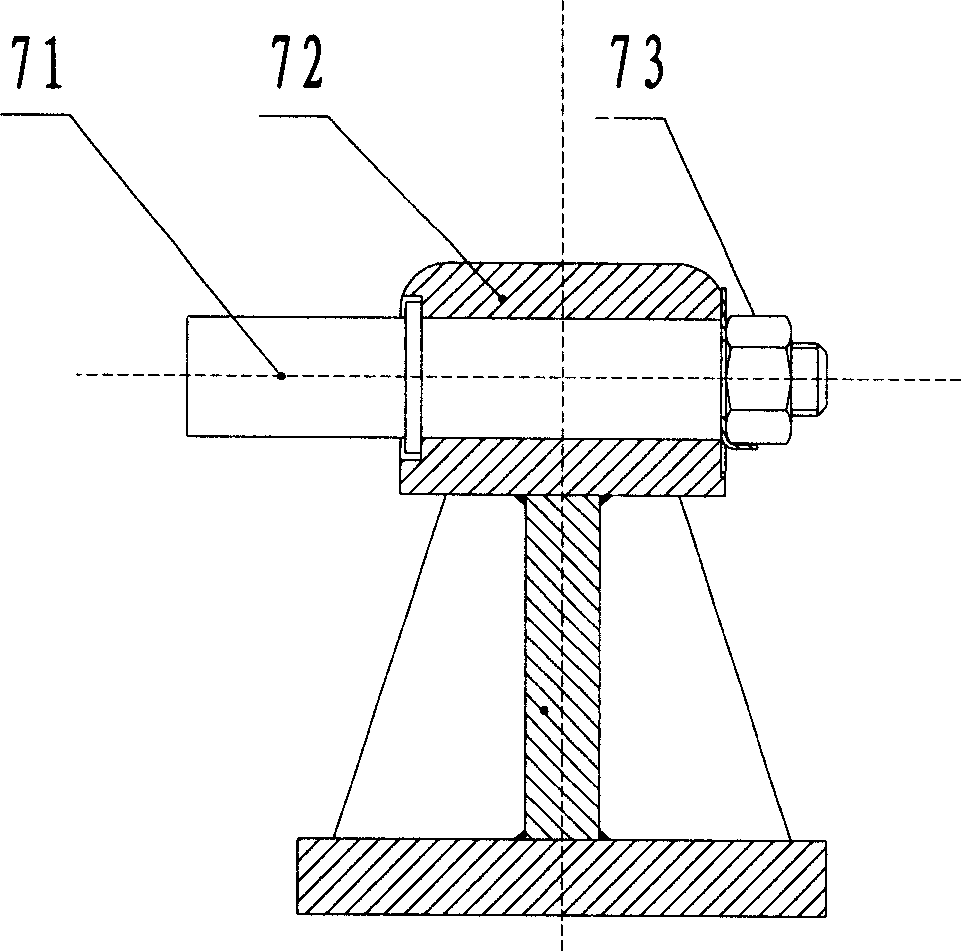

[0038] Such as figure 1 and figure 2 As shown, the full-hydraulic driven traveling shredder of the present invention includes a crushing roller 4, a crushing roller transmission mechanism 2, a traveling transmission mechanism 3, a traveling device 5, a hydraulic control system 8, a frame 1 and a track 7. The crushing roller transmission mechanism 2 and the traveling transmission mechanism 3 are arranged on the frame 1, the traveling device 5 includes the front wheel 11 and the rear wheel 6 which are arranged on the bottom of the frame 1 and supported on the track 7, and the crushing roller 4 is supported on the frame 1 on both sides. The hydraulic control system 8 is fixed on the frame 1, and it includes a crushing roller hydraulic control system 81 and a walking hydraulic control system 82. The traveling device 5 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com