Method for preparing polymer dispersed liquid crystal film

A technology for dispersing liquid crystals and polymers, applied in liquid crystals and related fields, can solve the problems of slow response speed, hysteresis of transmittance, low contrast of PDLC, etc. The effect of networking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

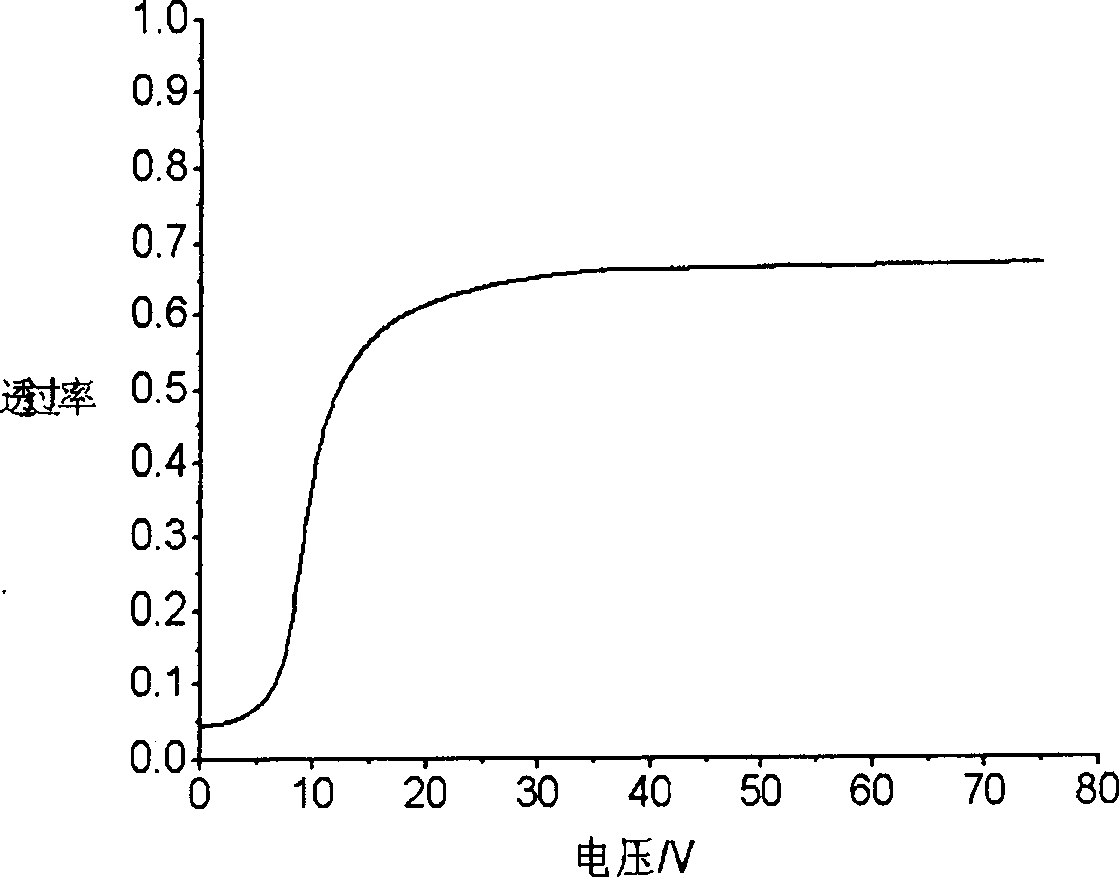

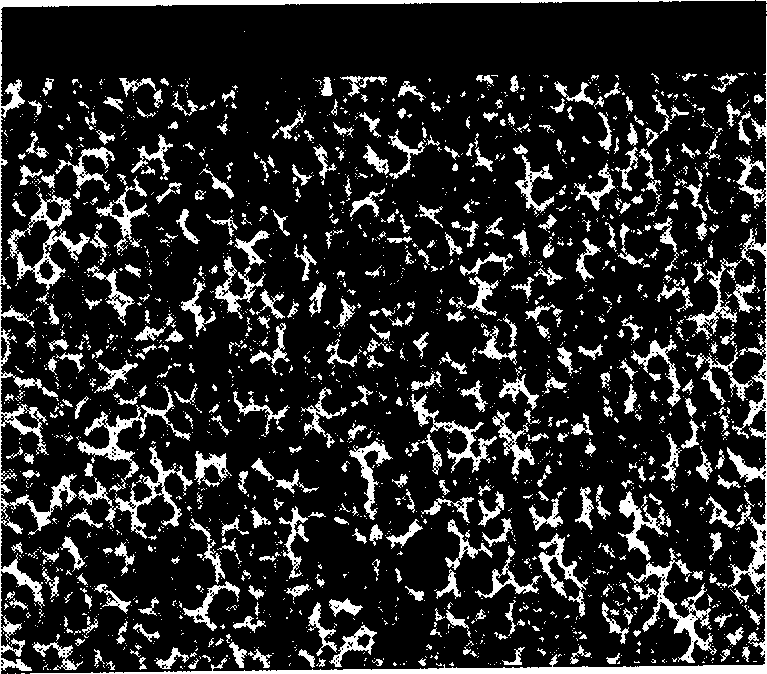

[0022] Add 5wt.% butylene glycol acrylate to hydroxypropyl acrylate containing -OH group (more than 99% in purity), and mix the monomer and liquid crystal (SLC7011-100, produced by Like Company) at a ratio of 20%: 80%. Mass ratio mixing, adding benzoin dimethyl ether and hexyl diisocyanate with 5% of the mass of the mixed monomers, stirring evenly, coating between two indium tin oxide films, and irradiating with 365nm ultraviolet light for 10 Minutes to photopolymerize the double bond in the monomer, and then heat to 120°C for 4 hours to thermally cross-link the -OH to obtain a polymer dispersed liquid crystal film. The film has good stability, good foldability, and good adhesion to the indium tin oxide film. The electro-optical performance curve of the film measured by a liquid crystal comprehensive parameter instrument is as follows: figure 1 . The photo of the monomer polymerization network under the scanning electron microscope is as follows figure 2 . -OH thermal pol...

Embodiment 2

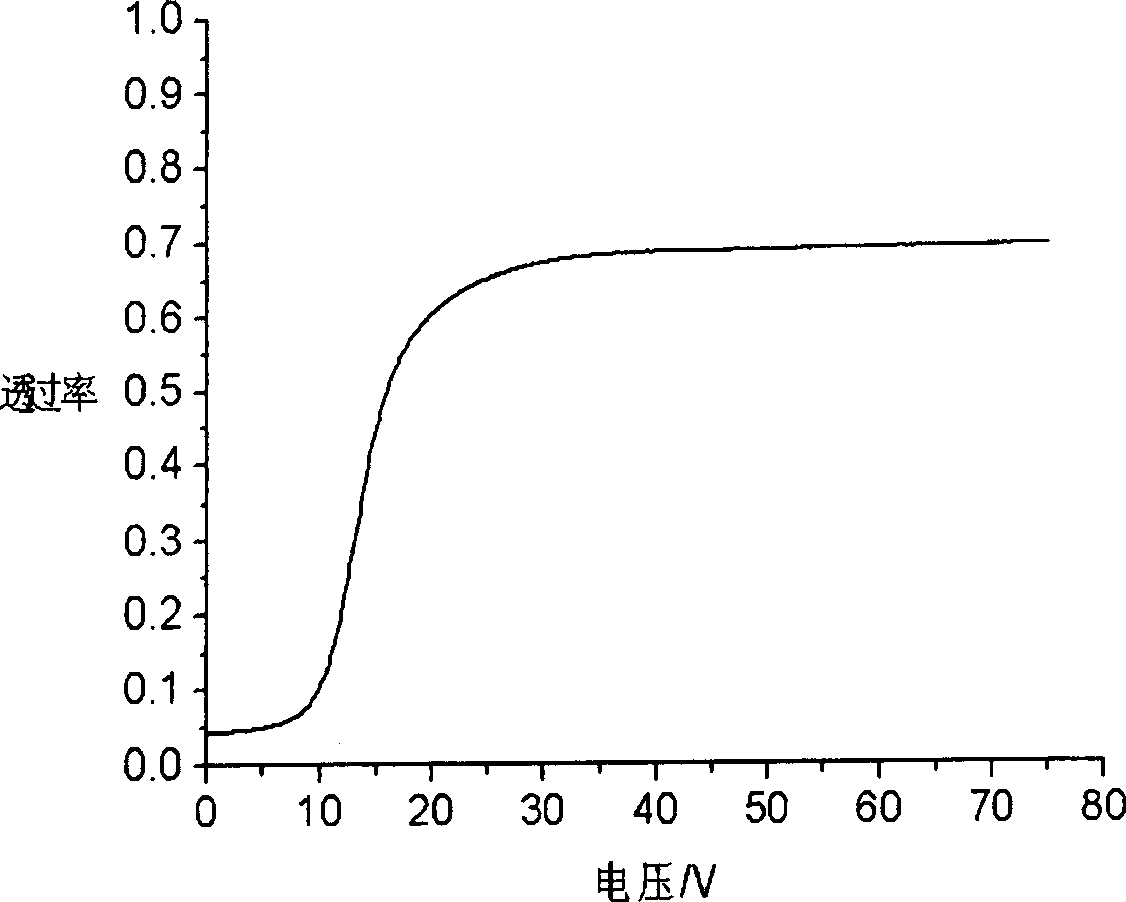

[0024] Add 5wt.% butylene glycol acrylate to hydroxypropyl acrylate containing -OH group (more than 99% in purity), and mix the monomer and liquid crystal (SLC7011-100, produced by Like Company) at a ratio of 10%:90%. Mass ratio mixing, adding benzoin dimethyl ether and hexyl diisocyanate with 5% of the mass of the mixed monomers, stirring evenly, coating between two indium tin oxide films, and irradiating with 365nm ultraviolet light for 10 Minutes to photopolymerize the double bond in the monomer, and then heat to 120°C for 4 hours to thermally cross-link the -OH to obtain a polymer dispersed liquid crystal film. The electro-optical performance curve of the film measured by a liquid crystal comprehensive parameter instrument is as follows: image 3 . The photo of the monomer polymerization network under the scanning electron microscope is as follows Figure 4 .

Embodiment 3

[0026] Add 5wt.% butanediol acrylate to hydroxypropyl acrylate (more than 99% in purity) containing -OH groups, and mix monomers and liquid crystals (SLC7011-100, produced by Like Company) at a ratio of 50%: 50%. Mass ratio mixing, adding benzoin dimethyl ether and hexyl diisocyanate with 5% of the mass of the mixed monomers, stirring evenly, coating between two indium tin oxide films, and irradiating with 365nm ultraviolet light for 10 Minutes to photopolymerize the double bond in the monomer, and then heat to 120°C for 4 hours to thermally cross-link the -OH to obtain a polymer dispersed liquid crystal film. The electro-optical performance curve of the film measured by a liquid crystal comprehensive parameter instrument is as follows: Figure 5 . The photo of the monomer polymerization network under the scanning electron microscope is as follows Image 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com