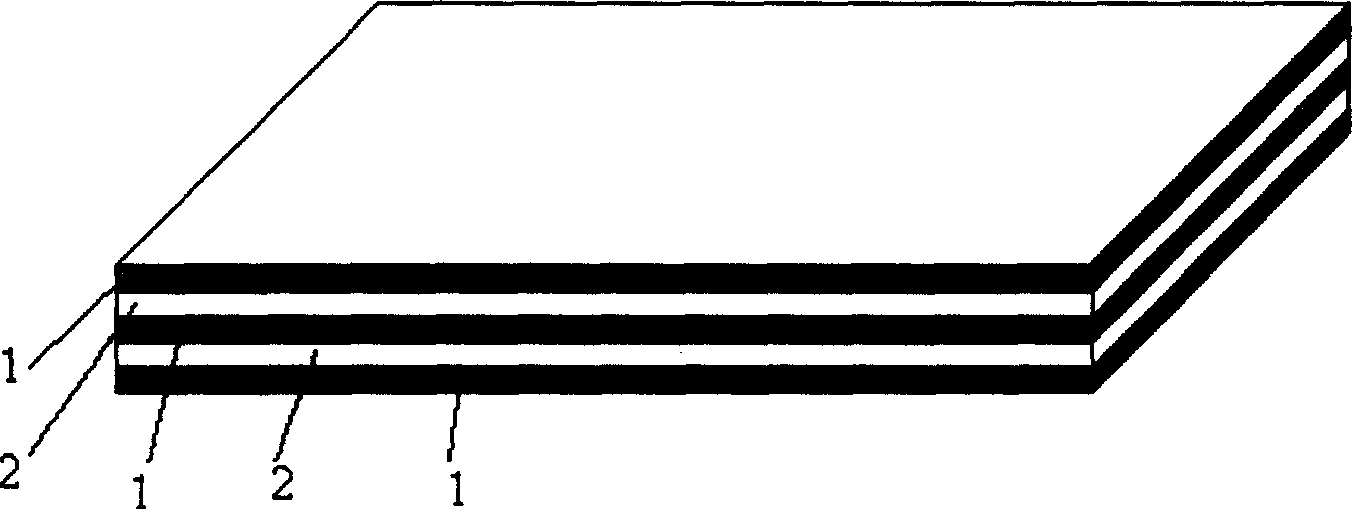

Swell type combustion-proof glass fiber reinforced polypropylene composite material and its preparation method

A flame retardant glass fiber and flame retardant polypropylene technology is applied in the field of flame retardant glass fiber reinforced polypropylene composite materials, which can solve the problems of insufficient flame retardant performance, can not meet the needs of fields with high flame retardant requirements, etc. performance, improved compatibility and effect of interfacial bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Polypropylene (Beijing Yanshan Petrochemical Company, brand K9035) 100 parts, ammonium polyphosphate (APP) (product of Jinan Taixing Fine Chemical Co., Ltd., polymerization degree greater than 1000) 18 parts, melamine (MEL) (Jinan Taixing Fine Chemical Co., Ltd. product) 12.5 parts, pentaerythritol (PER) (product of Jinan Taixing Fine Chemical Co., Ltd.) 8.5 parts, antioxidant 1010 (product of Shanghai Ciba Fine Chemical Co., Ltd.) 0.3 part, antioxidant 168 (product of Shanghai Ciba Fine Chemical Co., Ltd. ) 0.2 parts, the above raw materials were dried in an oven at 60°C for 24 hours, and after premixing, they were extruded and granulated in a twin-screw extruder with an aspect ratio of 40, a screw diameter of 30mm, and temperature control in 11 stages , the temperature of each section is as follows:

[0037] 1st stage: 130°C, 2nd stage: 150°C, 3rd stage: 175°C, 4th stage: 190°C, 5th stage: 190°C, 6th stage: 195°C, 7th stage: 195°C, 8th stage: 200°C, 9th stage: 200°C,...

Embodiment 2

[0041] In the preparation process of flame-retardant polypropylene pellets, 100 parts of polypropylene (Beijing Yanshan Petrochemical Company, brand K9035), 46 parts of APP (product of Jinan Taixing Fine Chemical Co., Ltd., polymerization degree greater than 1000), MEL (Jinan Taixing Fine Chemical Co., Ltd. product) 32 parts, PER (Jinan Taixing Fine Chemical Co., Ltd. product) 22 parts, all the other are with embodiment 1. Determination of its mechanical properties and oxygen index is shown in Table 1.

Embodiment 3

[0043] In the process of compounding with glass fibers, 7.5 parts of flame-retardant polypropylene pellets, 2 parts of glass fibers with a length of 6 mm, and the others are the same as in Example 2. Determination of its mechanical properties and oxygen index is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com