Heat treatment furnace employing heat pipe to quickly lower temperature

A heat treatment furnace and heat pipe technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as heat removal, achieve high heat exchange efficiency, and avoid large water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

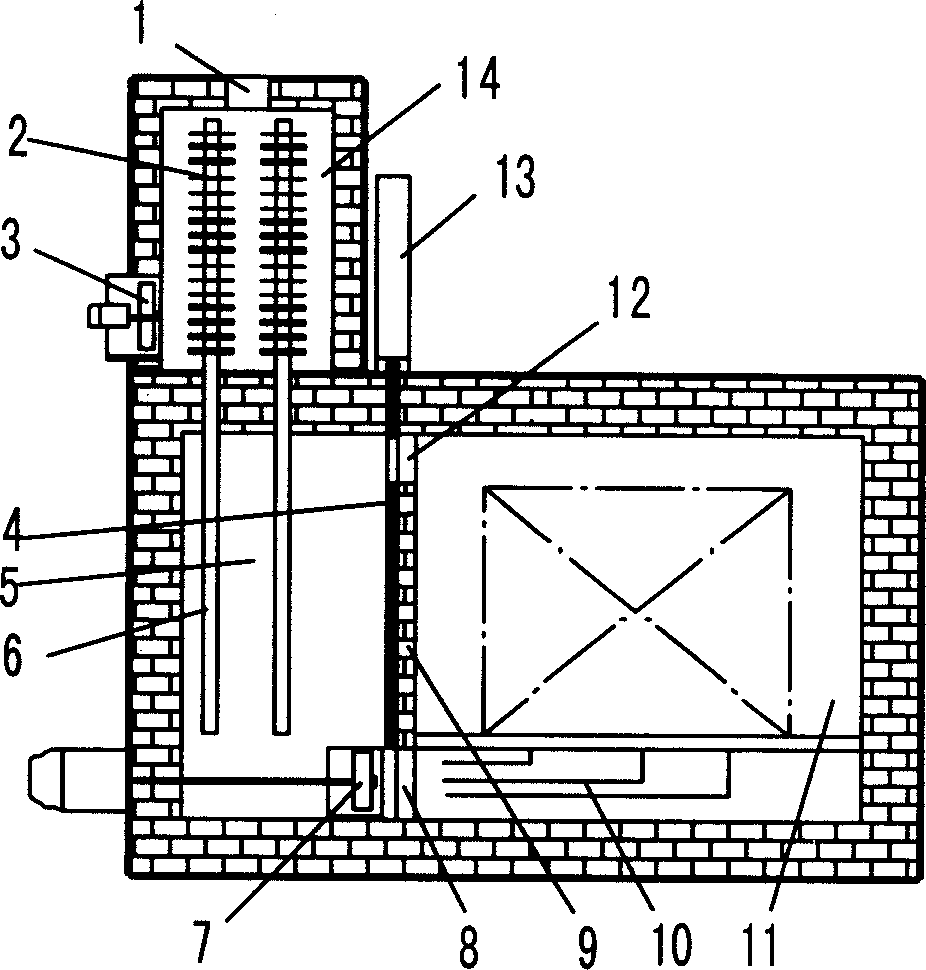

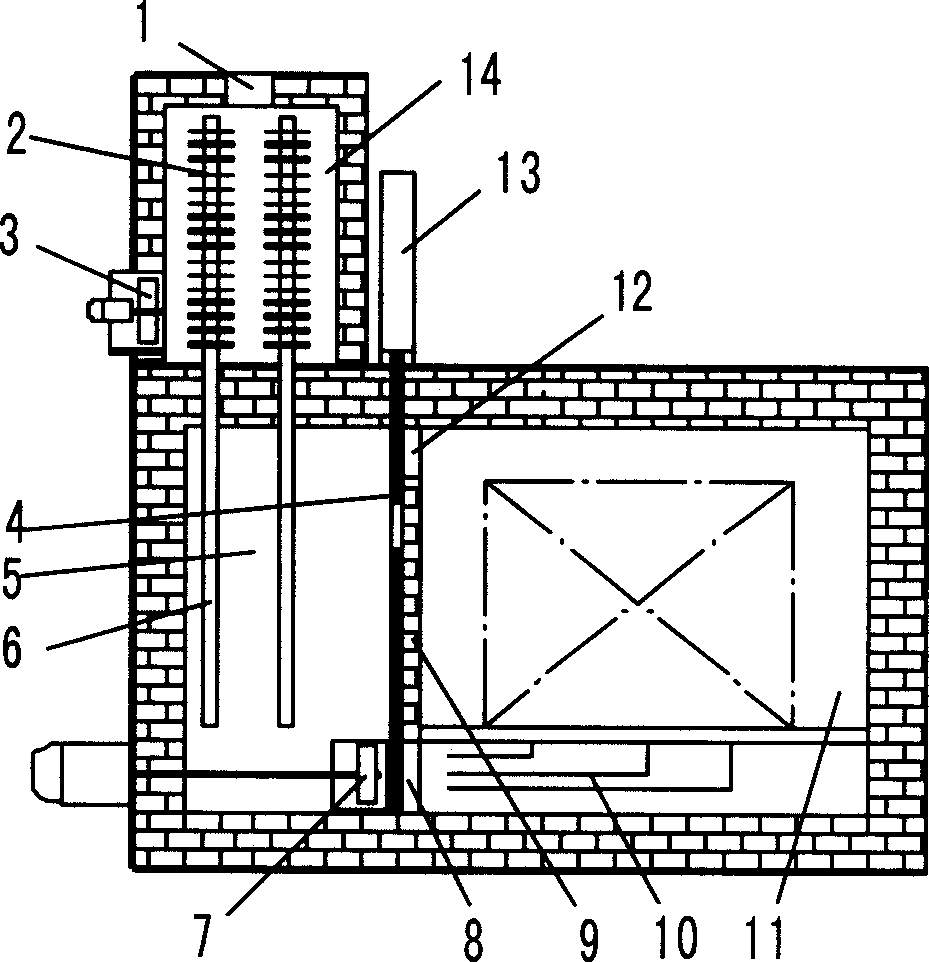

[0010] Such as figure 1 As shown, the present invention includes: hot air outlet 1, heat pipe heat dissipation end 2, cold air fan 3, windshield 4, heat exchange chamber 5, heat pipe heat absorption end 6, heat circulation fan 7, lower vent 8, heat insulation wall 9 , wind deflector 10, heating chamber 11, upper air vent 12, power push rod 13, cooling chamber 14, its connection mode is: the heat-absorbing end 6 of the heat pipe is installed in the heat exchange chamber 5, and the radiating end 2 of the heat pipe is installed in the cooling chamber 14, a cold air blower 3 is installed at the bottom of the cooling chamber 14, a hot air outlet 1 is set on the top of the cooling chamber 14, a heat insulating wall 9 is set between the heat exchange chamber 5 and the heating chamber 11, and a heat insulating wall 9 is provided on the heat insulating wall 9. The lower ventilation opening 8 and the upper ventilation opening 12 are provided with a windshield 4 adjacent to the heat insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com