Cylindrical flexible packed lithium ion storage cell with aluminum-plastic composite film

An aluminum-plastic composite film, lithium ion technology, used in secondary batteries, battery electrodes, battery pack components and other directions, can solve the problems of battery failure, heavy weight, battery performance deterioration, etc., to improve service life and reliability, The effect of reducing the likelihood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

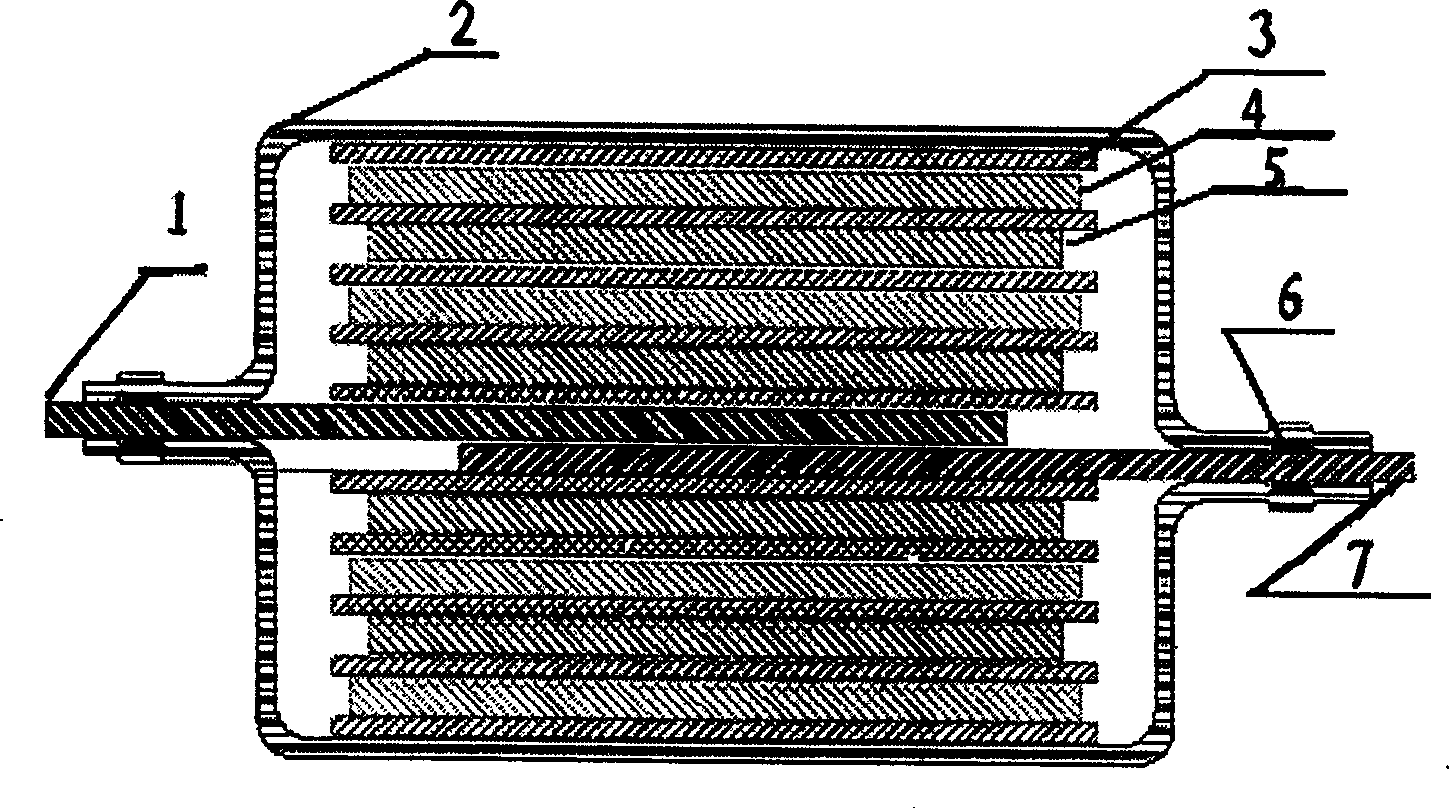

[0018] Cylindrical aluminum-plastic composite film flexible packaging lithium-ion battery, made of figure 1 As shown, the shell (2) is a cylindrical body of aluminum-plastic composite film flexible packaging, lithium manganate is selected as the positive electrode material, coated on the aluminum foil to make the positive electrode sheet (5), graphite is selected as the negative electrode material, coated on the copper foil The negative pole piece (4) is made, the aluminum foil is selected as the positive pole tab (1), the copper foil is used as the negative pole tab (7), and the casing is equipped with a diaphragm (3), a negative pole piece, a diaphragm and a positive pole piece Cylindrical electrode cores that are superimposed and wound together, the two ends and the middle of the electrode core are wound with fixed tape (not shown in the figure), and a pair of positive and negative pole tabs protruding from both ends are on the same center line, and The plane of the positiv...

Embodiment 2

[0020] Cylindrical aluminum-plastic composite film flexible packaging lithium-ion battery, made of figure 1 As shown, the shell is a cylindrical body of aluminum-plastic composite film flexible packaging, and the composition of lithium cobaltate and lithium nickelate in a weight ratio of 2:1 is selected as the positive electrode material, and is coated on an aluminum mesh to make a positive electrode sheet (5) , selecting soft carbon and hard carbon as the negative electrode material in a ratio of 2:1 by weight, coating it on a copper grid to make the negative pole piece (4), selecting aluminum foil as the positive pole lug (1), and nickel foil as Negative electrode tab (7), the shell is equipped with a cylindrical electrode core wound by the diaphragm (3), negative pole piece, diaphragm and positive pole piece, and the two ends and the middle part of the electrode core are wound and fixed Adhesive tape (not shown in the figure), the two pairs of positive and negative pole lug...

Embodiment 3

[0022] Cylindrical aluminum-plastic composite film flexible packaging lithium-ion battery, made of figure 1 As shown, the housing (2) is a cylindrical body of aluminum-plastic composite film flexible packaging, and the composition of lithium nickel cobaltate, lithium cobaltate and lithium iron phosphate in a weight ratio of 2:0.5:0.5 is selected as the positive electrode material, and coated on A positive pole piece (5) is made on stainless steel foil, metal lithium is selected as the negative pole material, coated on nickel foil to make the negative pole, aluminum foil is used to make the negative pole piece (4), and aluminum foil is chosen as the positive pole lug (1), The nickel foil is the negative electrode lug (7), and the shell is equipped with a cylindrical electrode core wound by the diaphragm (3), the negative pole piece, the diaphragm and the positive pole piece. The middle part is wound with fixed tape (not shown in the figure), the three pairs of positive and nega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com