Walking and bridging inner transport passage for open cast coal mine

An open-pit coal mine and stepping technology, which is applied to roads, roads, ground mining, etc., can solve the problems that affect the economic effect of open-pit mining, long distances of vehicles, and high transportation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

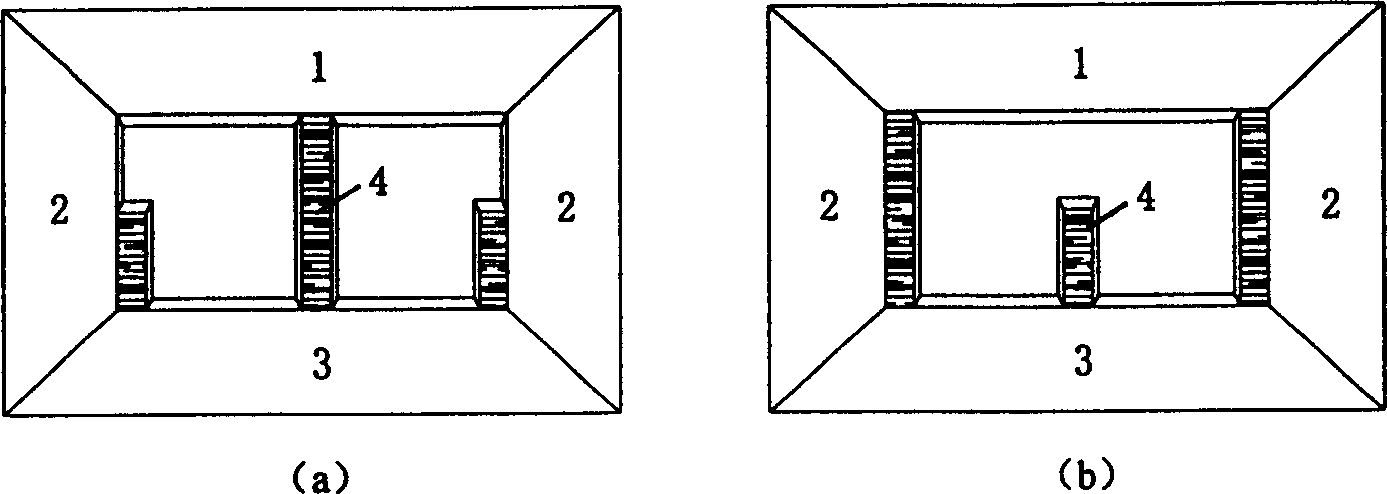

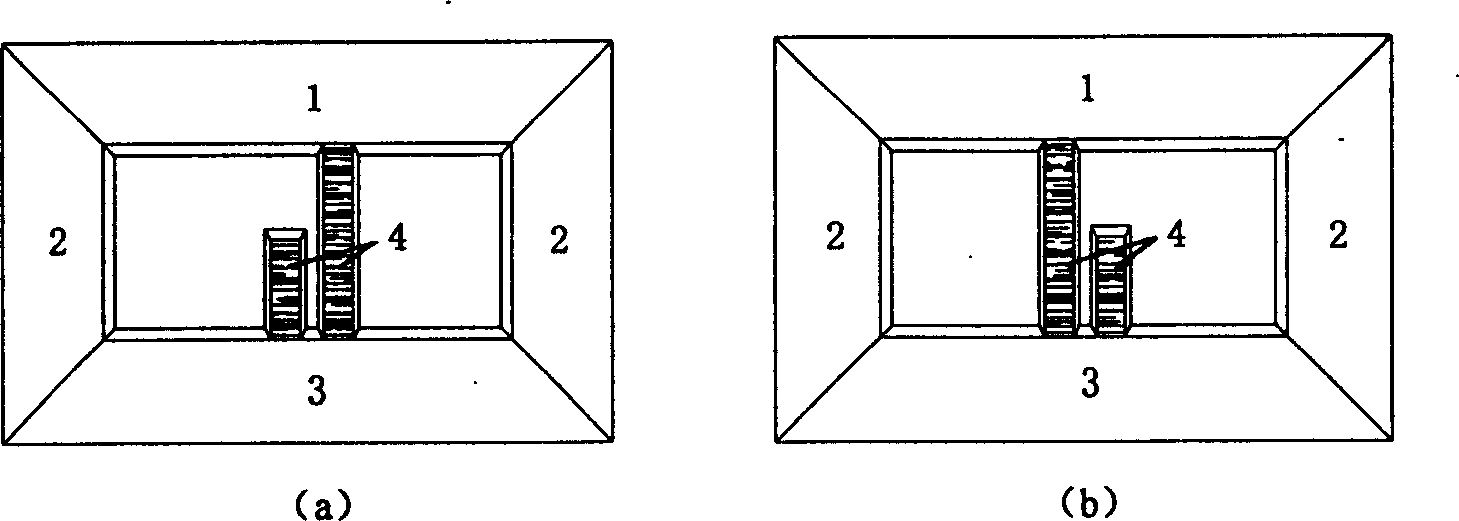

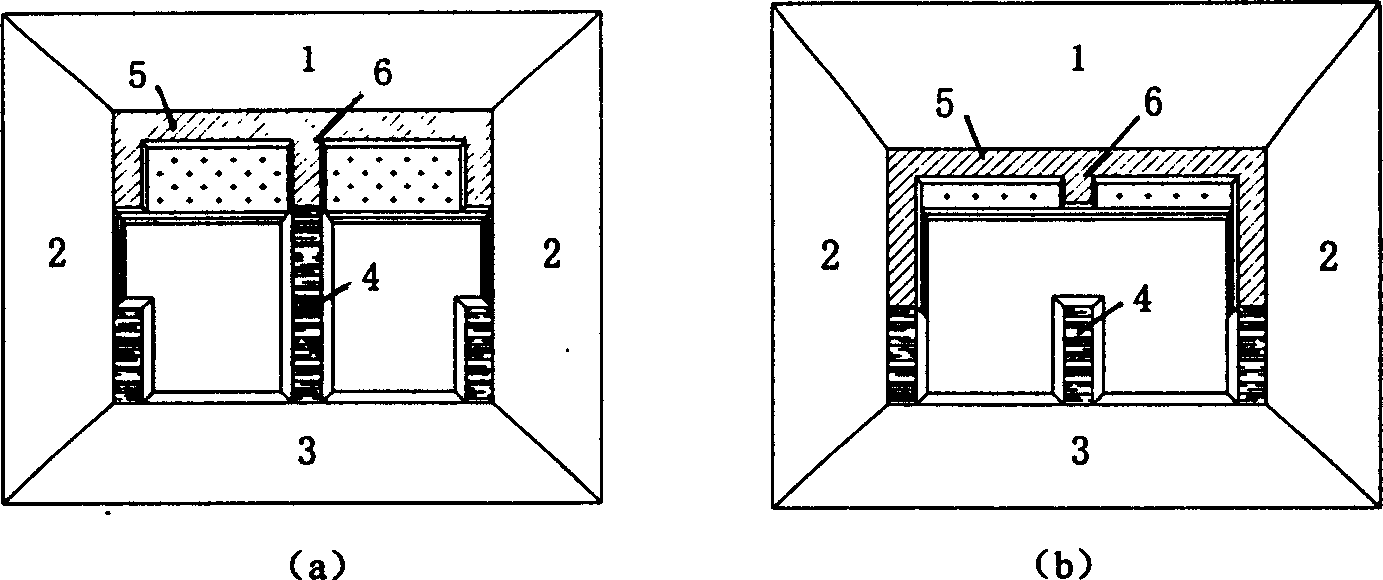

[0016] In the open-pit coal mine of the present invention, the step-by-step bridge connects the inner row of transportation passages. During the advancement of the open-pit coal mine excavation work side 1, the coal-bearing steps of the side sides 2 on both sides of the lower part of the stope are excavated according to the slope stability conditions, and the step-by-step method is adopted. Bridges are used to connect the inner row of transport passages, and the bridges are constructed in the following ways: a single bridge in the middle, a double bridge in the middle and a mixed bridge.

[0017] Take a single bridge in the middle: during the advancement process of the mining work gang 1 in the open-pit coal mine, the transportation path to the lower horizontal internal dump 3 is connected to an intermediate bridge 4 across the goaf, figure 1 As shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com