Automatic volume regulating and controlling method for gas-burning machine heat pump

A technology of capacity adjustment and gas engine, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., and can solve problems such as responsibility, poor real-time performance, lack of foundation, and impossible to establish mathematical models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

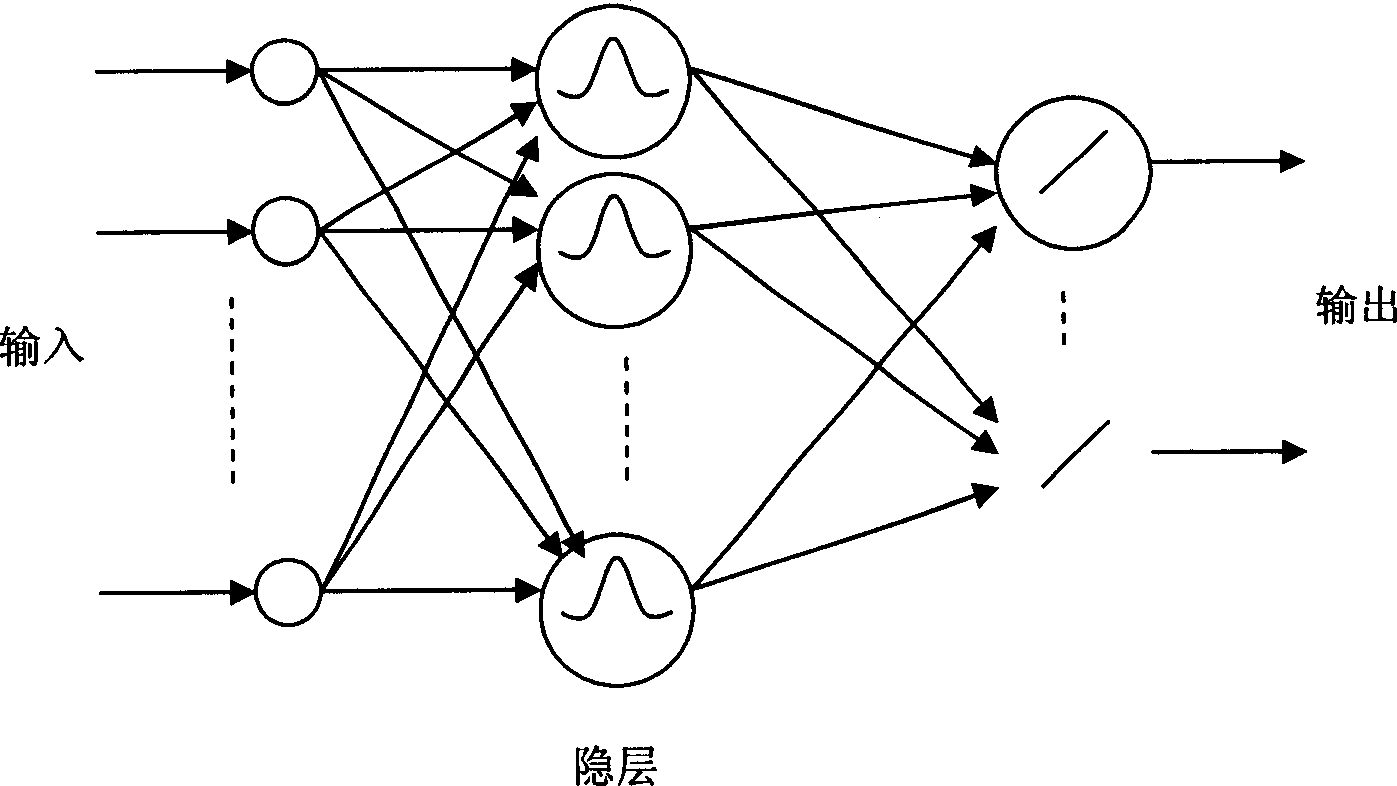

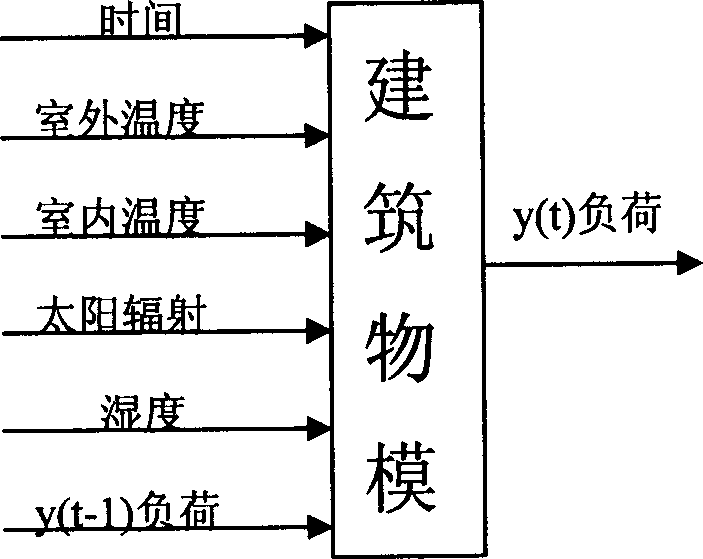

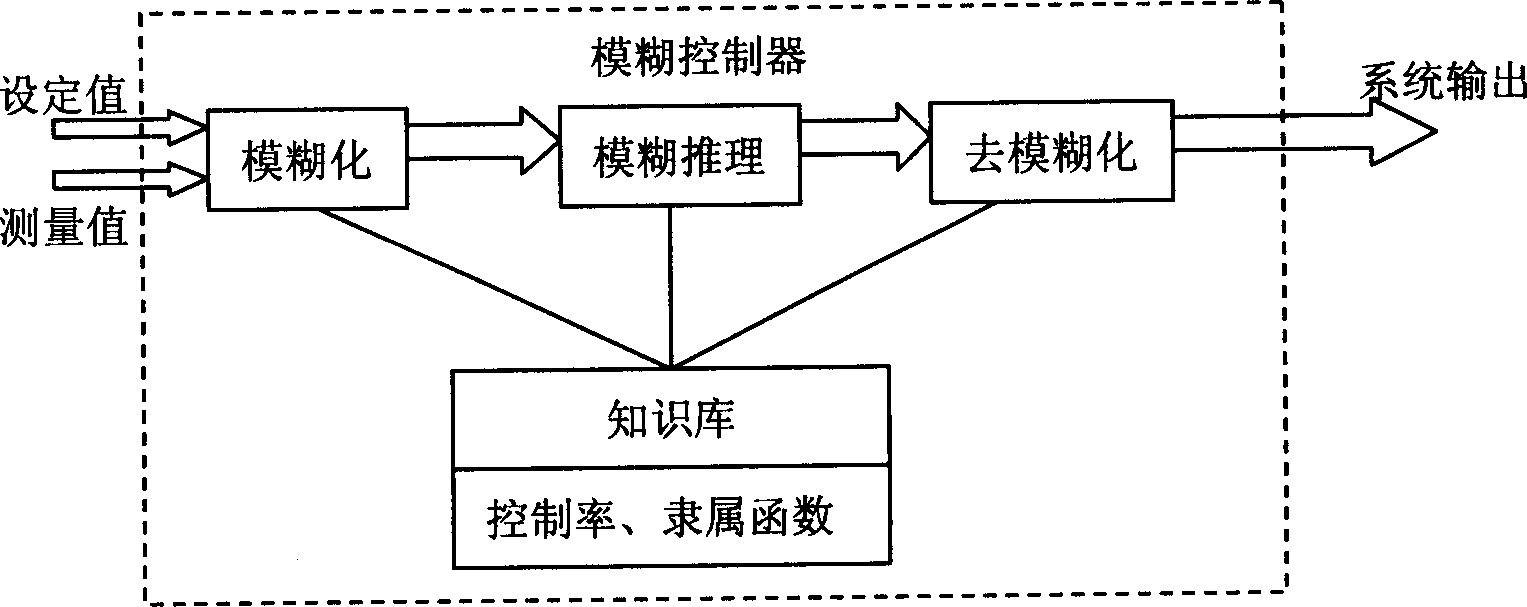

Method used

Image

Examples

Embodiment Construction

[0076] The following is attached Figure 4 , the implementation of the present invention is described as follows:

[0077] This embodiment is the operation of the hot and cold water unit of the gas engine heat pump, and the capacity adjustment method is to change the water supply temperature by fixing the water supply flow. The working process of this embodiment is as follows:

[0078] 1) Winter operation

[0079] Take the case of working on a certain day in winter as an example. When starting up in the morning, the outdoor temperature is 0°C. First, the weighted dynamic RBF neural network predicts that the building’s required heat load at the next moment will be 40kW, and this load is used as a feed-forward input. Then, the temperature sensor 15 detects the outlet water temperature of the heat pump unit, assuming that it is currently 20°C. Then the temperature 20°C and the set outlet water temperature of the unit (when the heating mode is running, the set outlet water temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com