Tin printing hidden antifake mark and producing method

An anti-counterfeiting label and production method technology, applied in the field of invisible anti-counterfeiting labels and production, can solve the problems of consumer inconvenience, high production cost, single method, etc., and achieve the effects of high printing accuracy, easy identification and unique process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

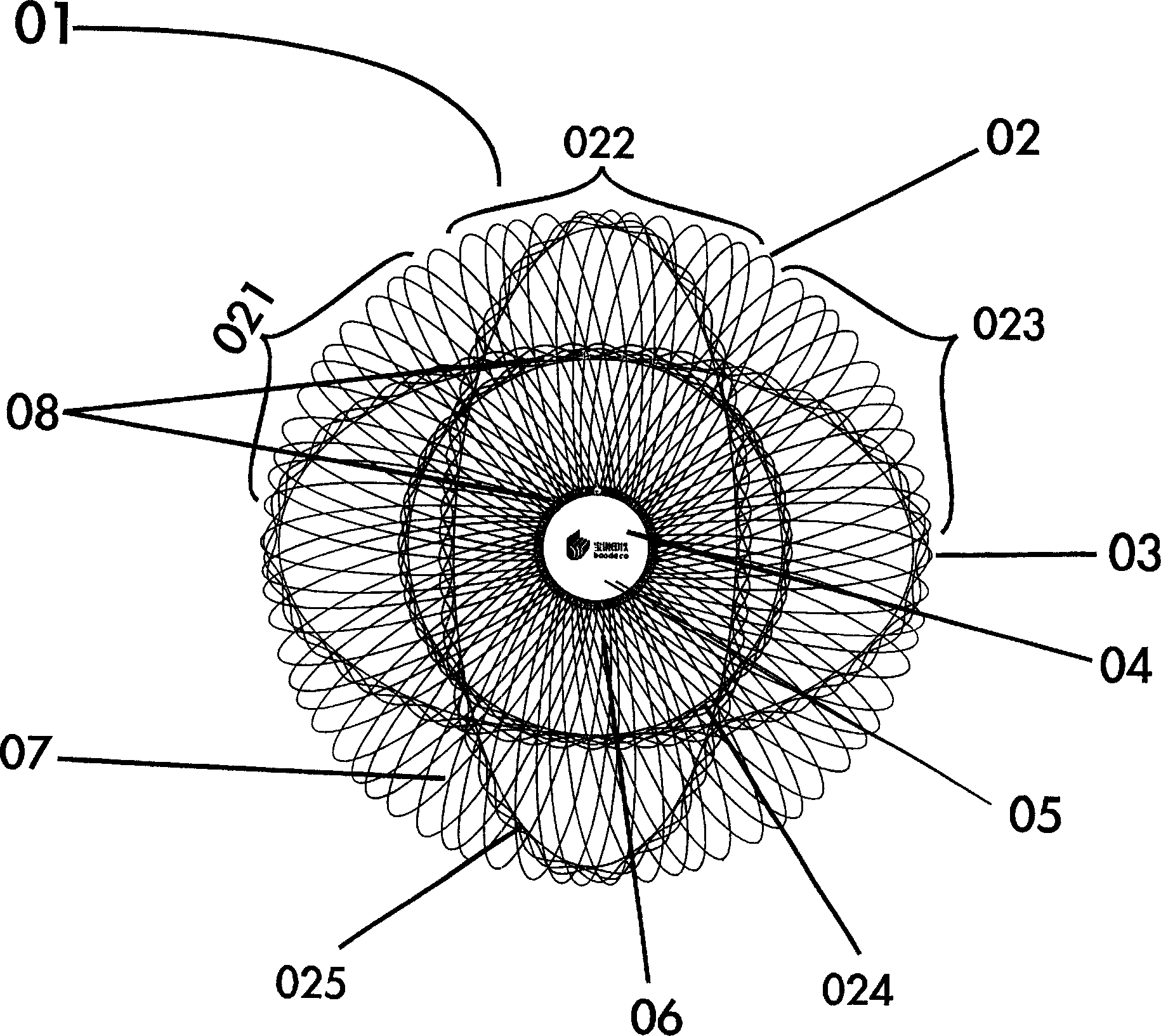

Image

Examples

Embodiment 1

[0074] The three major technological processes for making the method of printing iron anti-counterfeiting marks are as described above, and the specific process steps for making the invisible graphic relief printed on the colored anti-counterfeiting marks are:

[0075] (1) First make a flexible glazing plate

[0076] 1> make film (film) according to customer data file; In the present embodiment, customer's data file is " Baosteel printing iron ", and the film specification that makes is 1090 * 900mm format;

[0077] 2> drying out the flexographic plate with concave-convex three-dimensional relief on the flexible plate with the film made above; this flexographic plate is a polyester plate base resistant to ultraviolet varnish, and the thickness of the plate is 1.14 mm. Usually, there are three types of embossing on the flexo plate, one is to use the graphic part to protrude and the blank part to be concave; or to use the graphic part to be concave and the blank part to be protr...

Embodiment 2

[0093] All manufacturing processes are the same as in Example 1. Only in the conditions of the specific process steps of printing invisible graphic relief and printing color anti-counterfeiting marks, the proportion of ultraviolet fluorescent ink used by the sixth unit is different. The process step of concrete printing invisible graphic and text relief is identical with embodiment 1, and just condition and specific content are different, as:

[0094] Printing process steps of "invisible graphic relief":

[0095] (1) Making a flexible glazing plate

[0096] 1> make film (film) according to customer data file, in the present embodiment, customer data file is " ancient well ", what make is the film of 1090 * 50mm format specification;

[0097] 2>Use the film to print out the flexographic plate with concave-convex three-dimensional relief for the machine. This plate is a polyester plate base with UV-resistant varnish, and the plate thickness is 1.14 mm;

[0098] In this embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com