Martensitic stainless steel

一种马氏体不锈钢、化学组成的技术,应用在马氏体不锈钢领域,达到耐腐蚀性优良、韧性优良的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

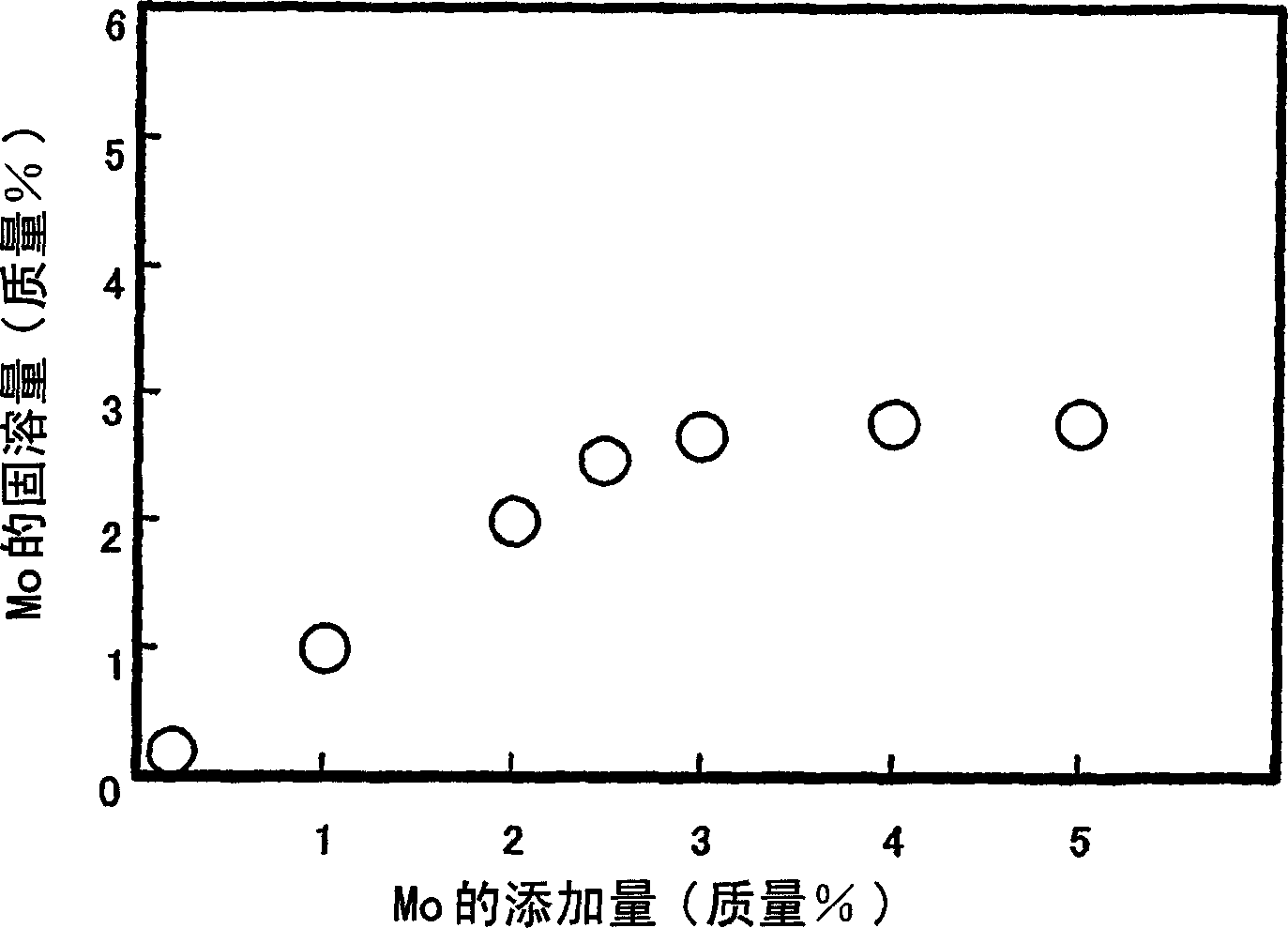

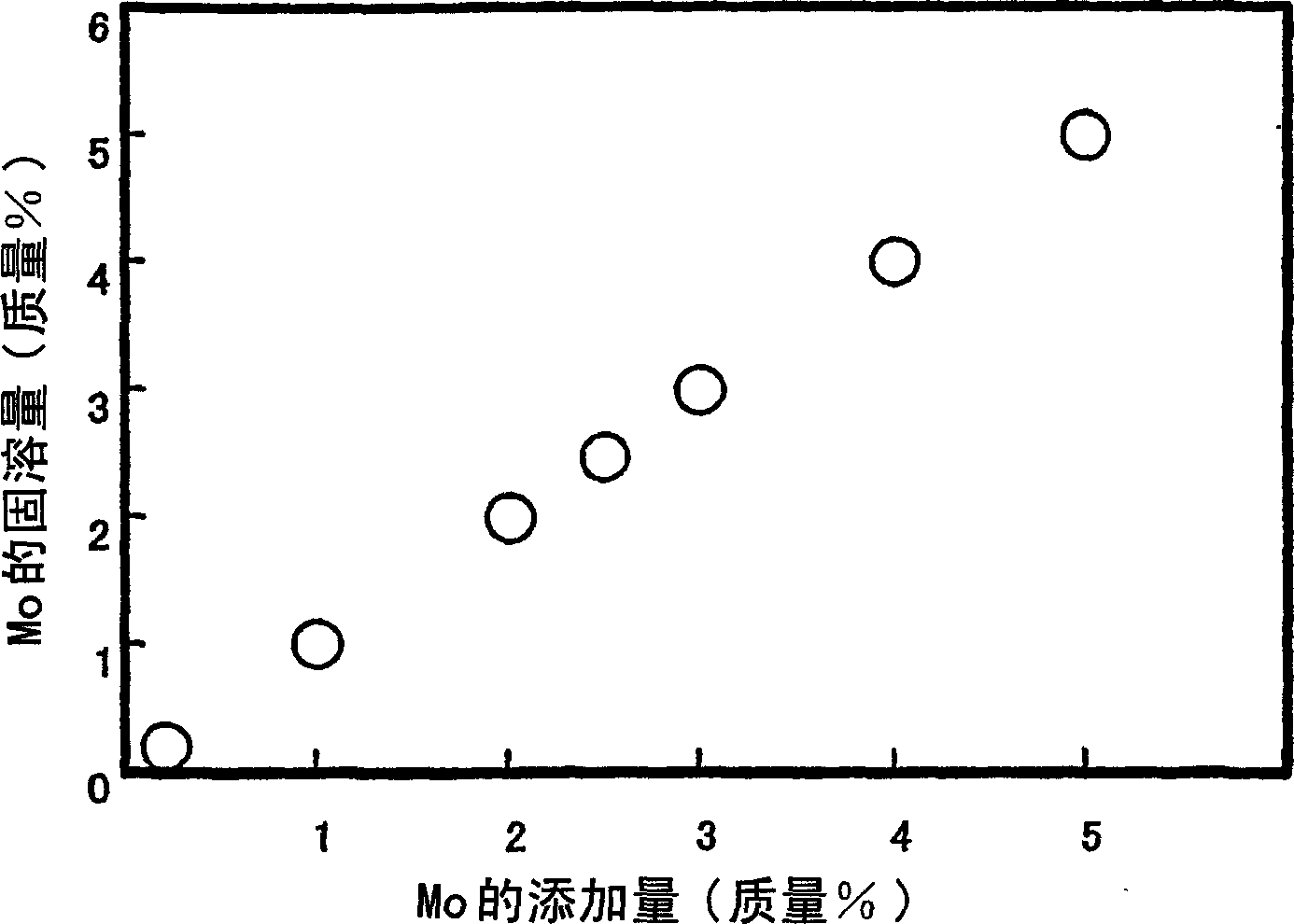

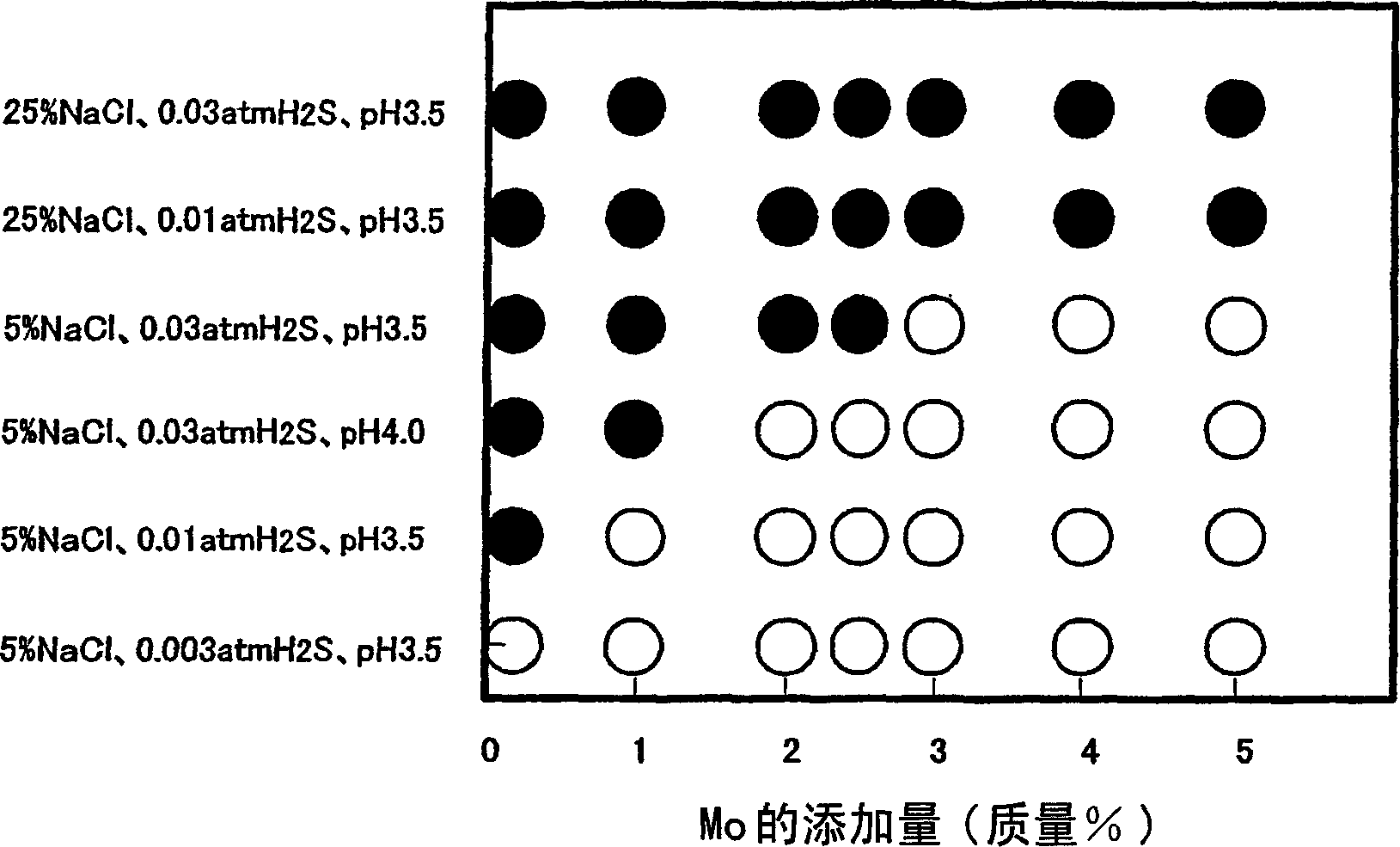

[0085] Steel having the chemical composition shown in Table 1 (the amount of Mo is the added amount) was melted and cast into ingot iron. These ingots were heated at 1250° C. for 2 hours, and then forged into ingots. These iron ingots were again heated at 1250° C. for 2 hours to obtain a rolled material having a thickness of 10 mm. After cooling down to room temperature, the calendered material was heated at 950° C. for 15 minutes, and then cooled with water. A part of them was left to stand after being cooled with water, and the remaining part was heat-treated by aging treatment at 100° C. to 620° C. for 1 hour after cooling with water.

[0086] In Table 1, steels A to U are steels with a high Mo content, steel V is a conventional super 13Cr steel, and steel W is a two-phase stainless steel. Among steels A to U with high Mo content, steels T and U do not satisfy the requirements of the present invention because the value of Ni-bal. is less than -4.5. The 2-phase stainless ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com