Method for welding shell belt by argon arc build-up welding with different copper double wires

A shell and heterogeneous technology, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of poor bonding strength between the elastic belt and the projectile body, poor weld formation, etc., to achieve increased strength, good weld formation, The effect of increased lethality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

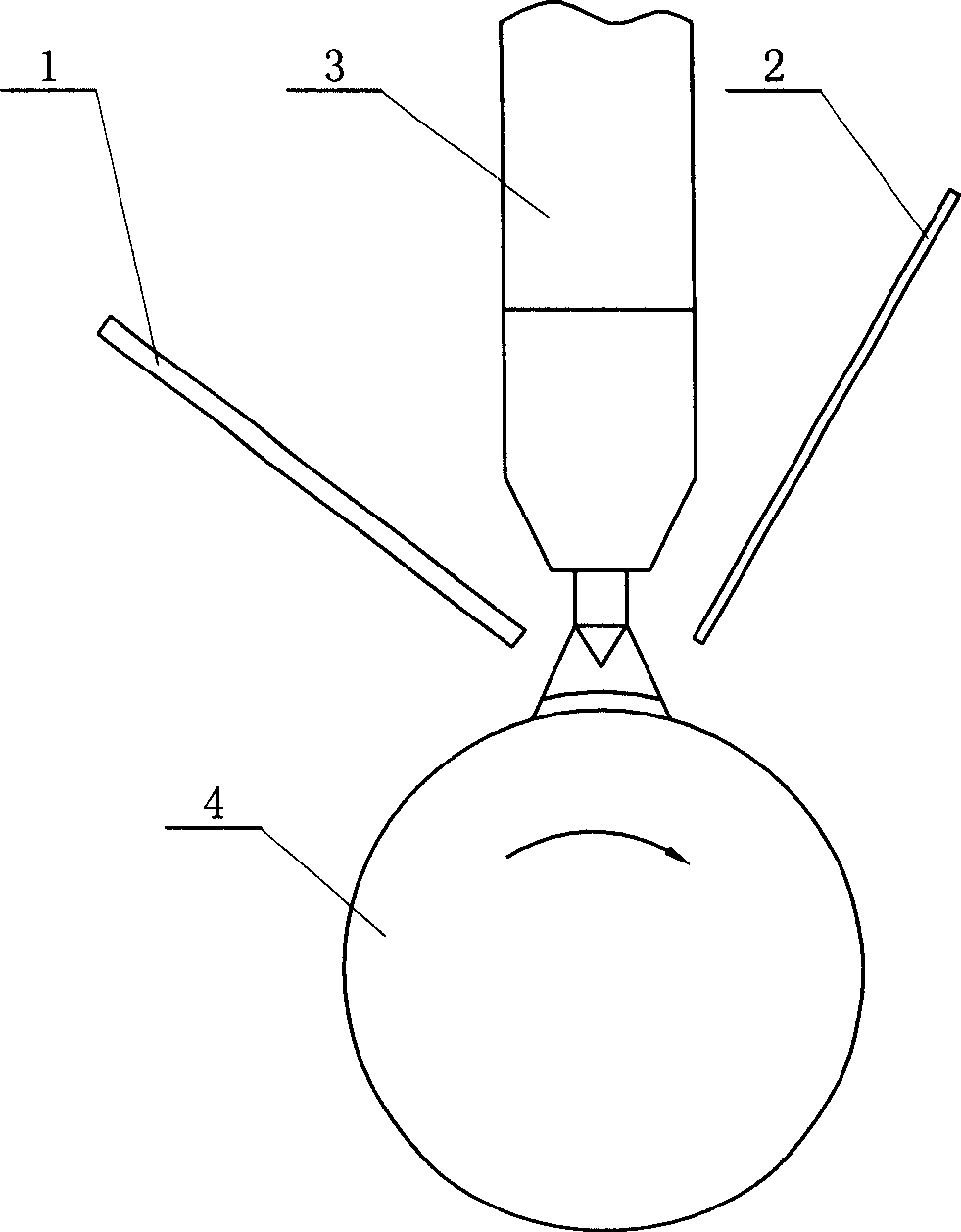

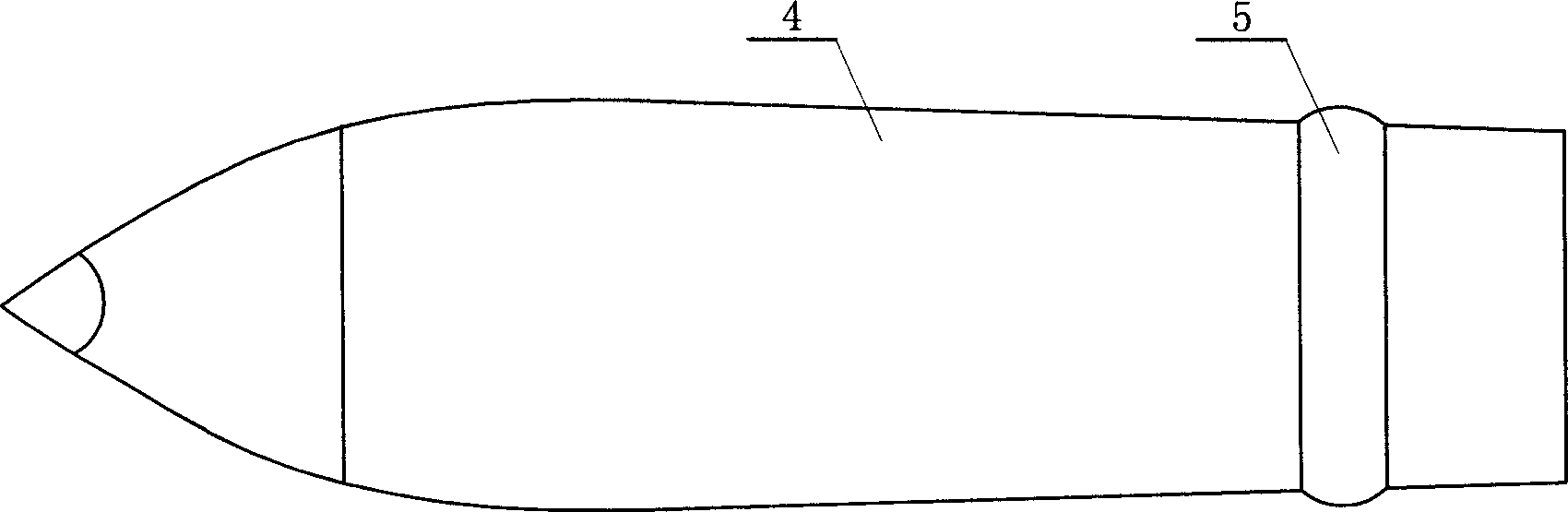

[0009] Specific implementation mode one: the steps of this implementation mode are as follows:

[0010] Step 1. Select red copper welding wire and brass welding wire. The brass welding wire with a zinc content of 5 to 35% is selected according to the weight percentage. ~1.6mm;

[0011] Step 2. Feed the red copper welding wire and the brass welding wire to the elastic belt welding place of the shell shell interface respectively by two TIG wire feeders. The feeding ratio of copper welding wire is 65-95% for red copper welding wire and 35-5% for brass welding wire according to the weight percentage. The circular interface is welded into a circular shell belt with a wall thickness of 2-5mm and a width of 5-50mm;

[0012] Step 3: Processing the surface of the shell band welded into a circular shape through step 2 by mechanical cutting.

[0013] For the elastic belt welded by the above method, two TIG wire feeders are used to feed the wire to the welded elastic belt, which can ef...

specific Embodiment approach 2

[0014] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the red copper wire is continuously heated during the wire feeding process. The temperature of heating the red copper wire is 200-600° C., and the heating of the red copper wire can improve the welding efficiency.

specific Embodiment approach 3

[0015] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in Step 2, the red copper wire is 65% and the brass wire is 35% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com