Iron and steel gas based smelting and reducing process with iron-ore powder pre-reduced

A technology of iron ore powder and process, which is applied in the fields of iron and steel metallurgy, non-blast furnace ironmaking and hydrogen energy metallurgy, can solve the problems of high energy consumption, high cost, long investment payback period, etc., and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

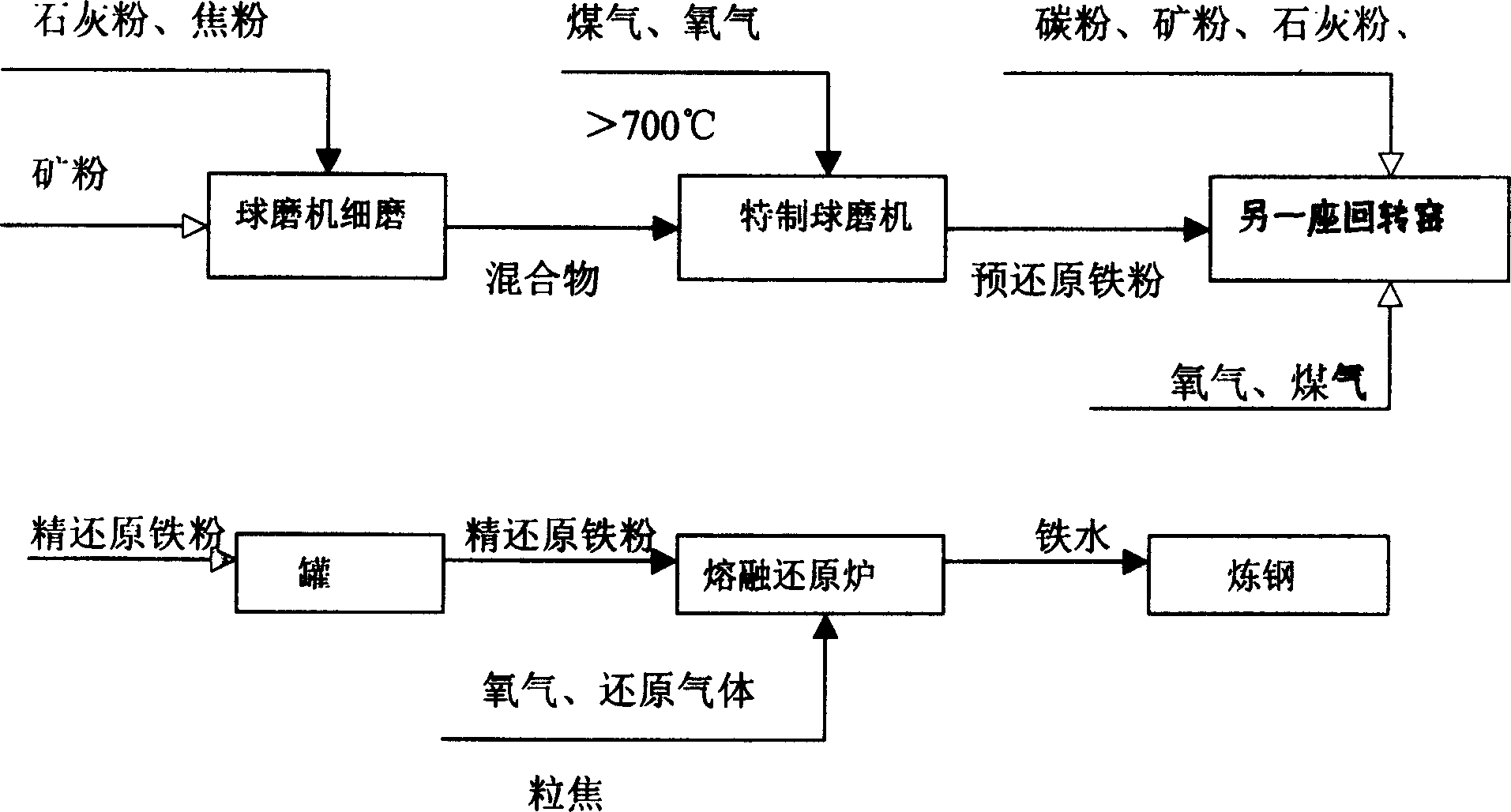

[0013] In the iron ore powder pre-reduction gas-based smelting reduction ironmaking and steelmaking process invented, the iron ore powder is used as raw material, which is directly fed into the mill together with coal powder or low-quality coke powder and lime powder, and finely processed by a special ball mill. Grinding, heating to 650-680°C, adding part of oxygen and gas for pre-reduction. The pre-reduced iron powder is added to the mixed carbon powder, mineral powder, lime powder, and reduced iron, and then blended into another rotary kiln. Oxygen and gas are added to make the pre-reduced iron powder go through the rotary kiln and heat up to 850°C-900°C. Further heating and fine reduction, the reduced product, after dust removal and secondary reduction, is put into a heat preservation tank while it is hot, and then poured into a smelting reduction furnace, and oxygen and coal gas are used as heat sources, and hot reduced iron and part of granules are added. Coke (low-streng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com