Electret microphone comprising spring washer

A technology of electret microphones and gaskets, which is applied to electret electrostatic transducers, electrostatic transducer microphones, sensors, etc., can solve the problems of reducing manufacturing output, diaphragm bending, and errors, and prevent manufacturing costs from increasing , The effect of preventing an increase in the number of parts and improving manufacturing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

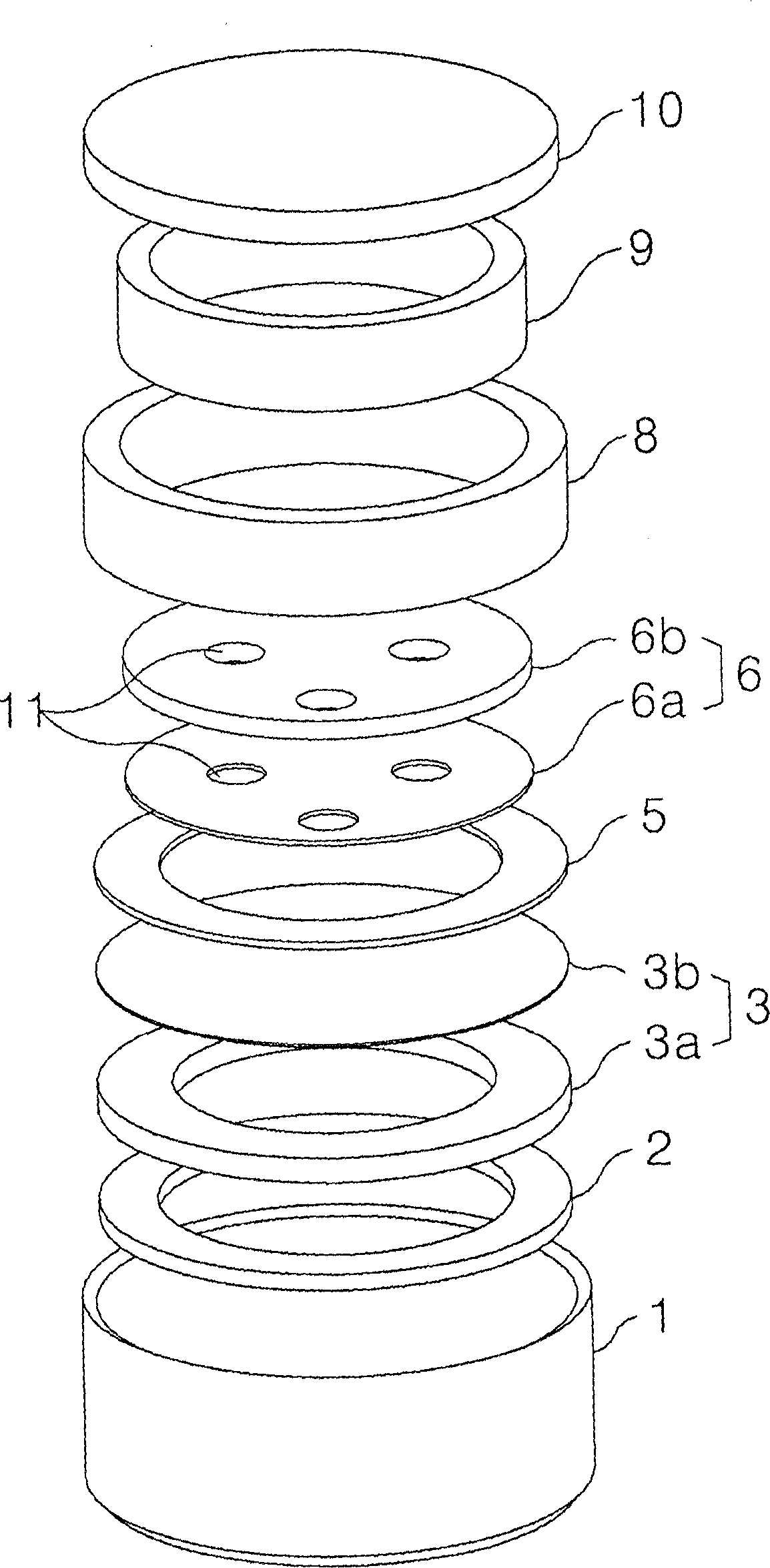

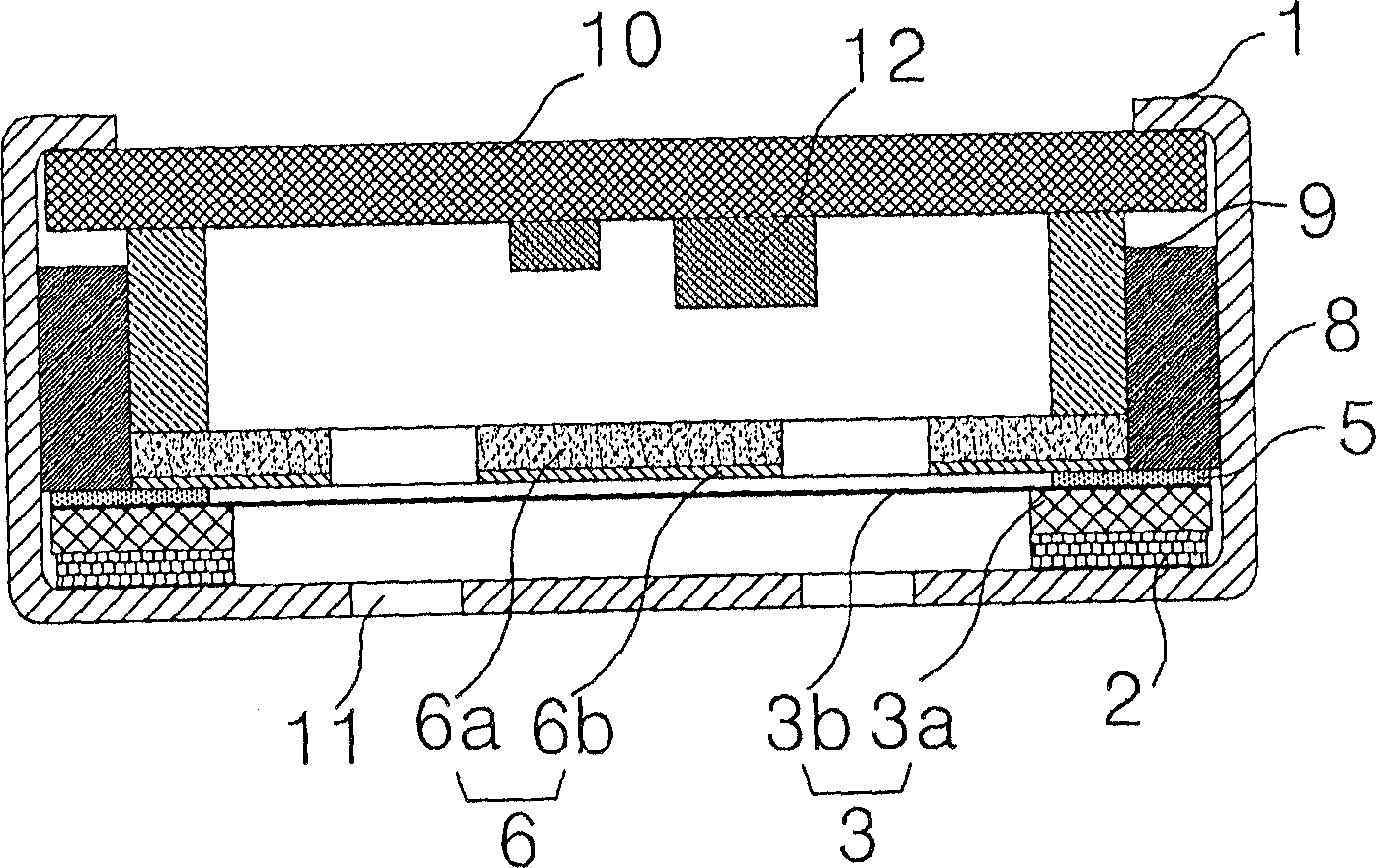

[0038] figure 1 is a sectional view showing a back-type electret condenser microphone according to a first embodiment of the present invention, and figure 2 is the assembled figure 1 Cutaway view of a condenser microphone.

[0039] refer to figure 1 and figure 2 , The ECM according to the present invention includes: a housing 1 , a washer spring 2 , a vibration plate 3 , a spacer 5 , a back plate 6 , a first base ring 8 , a second base ring 9 and a printed circuit board 10 .

[0040]The housing 1 accommodates the washer spring 2, the vibrating plate 3, the spacer 5, the back plate 6, the first base ring 8 and the second base ring 9, and protects internal components from external impact. In addition, the casing 1 prevents noise and electromagnetic interference noise from entering from the outside, so that the conversion of sound into electrical signals can be performed smoothly. The casing 1 is electrically connected to the vibration plate 3 and the printed circuit board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com